Of course you're right, it's just that it's so interesting.The more I see of this project, the more I wonder why you are reinventing the drive train.

Measurements of the Cutlass Bearing?

- Thread starter RSHunter27

- Start date

Well the manager of the marina let me know that I got less than 30 days to still be in a position with any electricity and such. All the docs are getting moved further out on to the lake. Unless we get a storm with a bunch of water I'll not be able to stay on the boat. So I'm going to try and finish off all my projects. And between now and then, I need to decide whether I want to leave her here in the middle of a lake where I can't do much with her and go back to Florida and find my blue water boat. Or maybe just have her hauled out of here and sail her to Florida. Anyway that's another story. I understand what you guys are getting at. Sometimes simple is better. But I have a problem. I always have to make things better. And if things are problematic, I have a need to solve the problems. When I started the project on this boat there were a few that thought I was going too far like taking the teak rails off and putting on stainless steel so on and so forth. The bottom line is I'm likely going to do what I'm likely going to do. Whatever others have to say about it. Kind of been that way my whole life. I really don't expect any praise or anything from anybody. I'm doing what I want to do just cuz I want to do it. Right wrong or indifferent. Just thought this was a good forum too share my endeavor with. I'm going to see it through, so stick with me and comment if you feel like it and we'll see if my hair brained plans are worth it.Of course you're right, it's just that it's so interesting.

I hate to keep pissing on your corn flakes like this @RSHunter27 , but if you do decide to incorporate the tapered roller bearing as a thrust bearing, you will have to agree never use the engine in reverse. And I don't know if that's really the best idea for your boat.

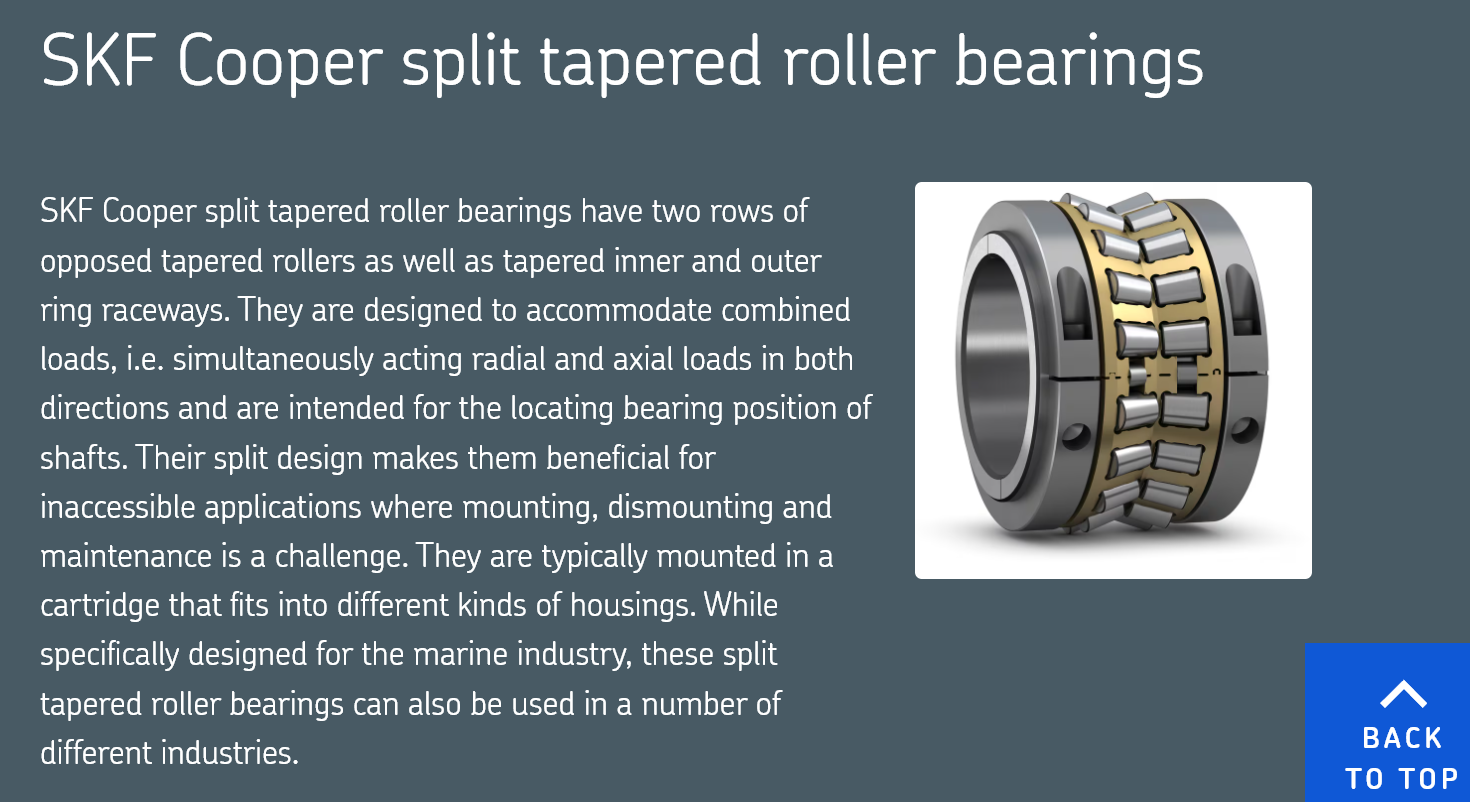

In order to have resistance to the thrust supplied by the shaft, you'll need a double ended, tapered, roller bearing to accommodate both forward and reverse thrust.

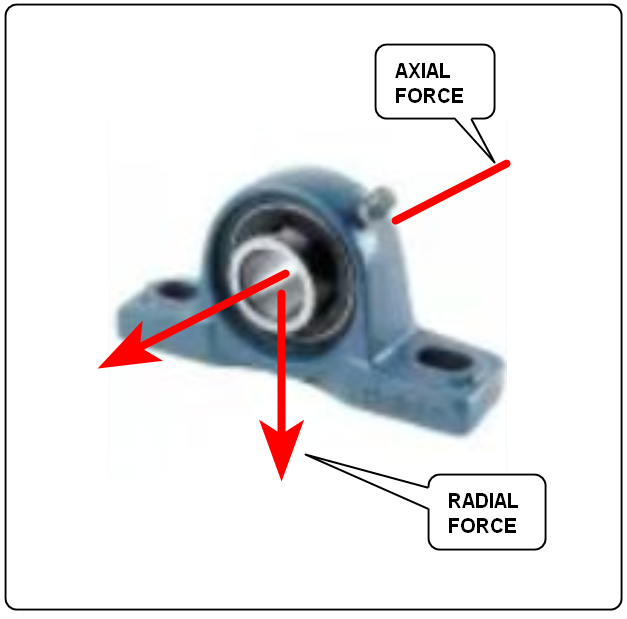

If it turns out your newly acquired bearing will not tolerate axial forces, you may find yourself looking at this bearing for the internals of a new pillow block housing should you go for that mounting configuration :

A pillow block enclosure is the ideal device to absorb minor misalignment as your hull flexes.

In order to have resistance to the thrust supplied by the shaft, you'll need a double ended, tapered, roller bearing to accommodate both forward and reverse thrust.

If it turns out your newly acquired bearing will not tolerate axial forces, you may find yourself looking at this bearing for the internals of a new pillow block housing should you go for that mounting configuration :

A pillow block enclosure is the ideal device to absorb minor misalignment as your hull flexes.

Your boat, and your decisions certainly.Well the manager of the marina let me know that I got less than 30 days to still be in a position with any electricity and such. All the docs are getting moved further out on to the lake. Unless we get a storm with a bunch of water I'll not be able to stay on the boat. So I'm going to try and finish off all my projects. And between now and then, I need to decide whether I want to leave her here in the middle of a lake where I can't do much with her and go back to Florida and find my blue water boat. Or maybe just have her hauled out of here and sail her to Florida. Anyway that's another story. I understand what you guys are getting at. Sometimes simple is better. But I have a problem. I always have to make things better. And if things are problematic, I have a need to solve the problems. When I started the project on this boat there were a few that thought I was going too far like taking the teak rails off and putting on stainless steel so on and so forth. The bottom line is I'm likely going to do what I'm likely going to do. Whatever others have to say about it. Kind of been that way my whole life. I really don't expect any praise or anything from anybody. I'm doing what I want to do just cuz I want to do it. Right wrong or indifferent. Just thought this was a good forum too share my endeavor with. I'm going to see it through, so stick with me and comment if you feel like it and we'll see if my hair brained plans are worth it.

I have my ways of doing things, and I can certainly be labeled obsessed in certain ways.

Sounds like you have a lot going on, and a lot of decisions to make…and only you can make them…just trying to offer some friendly advice and ask questions to try and understand your issues.

Keep us posted, I am interested in the CV joint idea….As @Ralph Johnstone said “…darn interesting”.

Greg

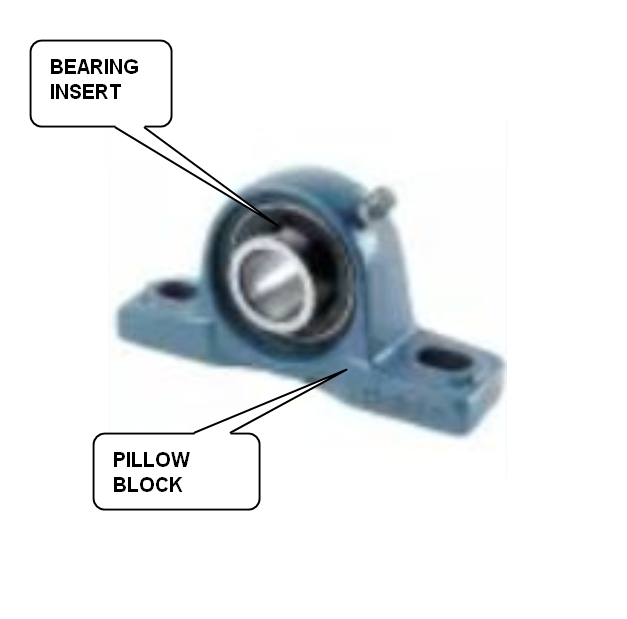

It is a pillow block.I hate to keep pissing on your corn flakes like this @RSHunter27 , but if you do decide to incorporate the tapered roller bearing as a thrust bearing, you will have to agree never use the engine in reverse. And I don't know if that's really the best idea for your boat.

In order to have resistance to the thrust supplied by the shaft, you'll need a double ended, tapered, roller bearing to accommodate both forward and reverse thrust.

If it turns out your newly acquired bearing will not tolerate axial forces, you may find yourself looking at this bearing for the internals of a new pillow block housing should you go for that mounting configuration :

View attachment 219012

A pillow block enclosure is the ideal device to absorb minor misalignment as your hull flexes.

It is a pillow block.

Attachments

-

32.1 KB Views: 89

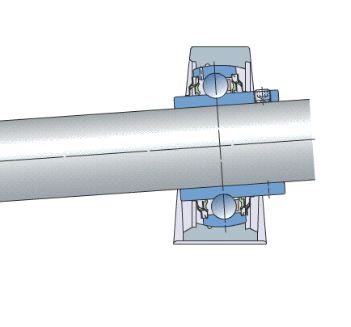

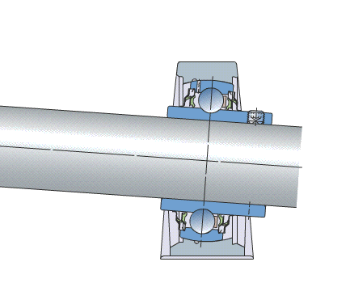

A pillow block is the housing for the bearing "guts" or insert which allows for a few degrees of misalignment by allowing the bearing to rotate a few degrees within the pillow block :

The exterior of the bearing insert and the interior of the pillow block are slightly spherical to allow for this small amount of movement.

It's the bearing insert which does not appear to be able to withstand any axial thrust as described in the label which you posted in your post #38

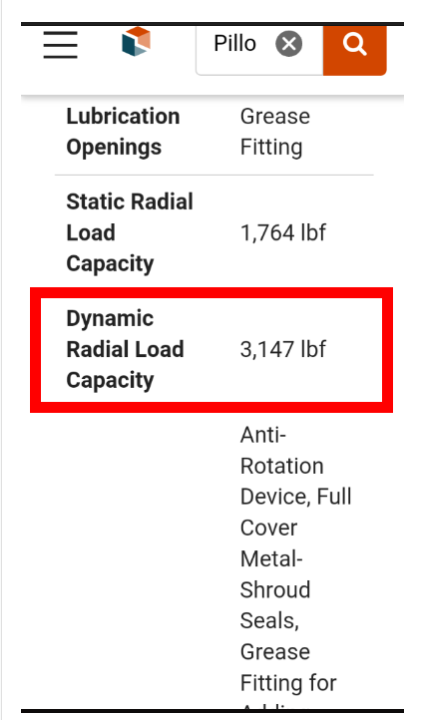

It can only withstand a radial force of 3,147 lbs. when rotating:

The exterior of the bearing insert and the interior of the pillow block are slightly spherical to allow for this small amount of movement.

It's the bearing insert which does not appear to be able to withstand any axial thrust as described in the label which you posted in your post #38

It can only withstand a radial force of 3,147 lbs. when rotating:

LoadsA pillow block is the housing for the bearing "guts" or insert which allows for a few degrees of misalignment by allowing the bearing to rotate a few degrees within the pillow block :

View attachment 219040 View attachment 219041

View attachment 219042

The exterior of the bearing insert and the interior of the pillow block are slightly spherical to allow for this small amount of movement.

It's the bearing insert which does not appear to be able to withstand any axial thrust as described in the label which you posted in your post #38

View attachment 219043

It can only withstand a radial force of 3,147 lbs. when rotating:

View attachment 219044

Equivalent bearing loads, minimum load, axial load carrying capacity

For detailed information, refer to Insert bearings / Loads.

Permissible housing loads

Pillow block housings made of cast iron or stainless steel, accommodate at least the same dynamic and static loads as the incorporated insert bearings. They can also endure peak loads or varying axial loads.

Housings made of composite material (including SKF Food Line units) accommodate at least the same static loads as the incorporated insert bearings.

Pressed steel housings have a lower load carrying capacity than the suitable insert bearings. The permissible radial load for the selected housing is listed in the technical specifications for each product (product table). The axial load should not exceed 20% of the permissible radial load.

Loads parallel to the support surface

When the load angle acting on the housing is between 55° and 120° (fig. 1), one of the following precautions should be taken:

- Stops should be provided in the direction of the load.

- Cast iron housings can be dowelled to the support surface.

SY and SYJ series units have dimples indicating dowel pin positions. Dimensions are listed in the technical specifications for each product (product table).

This is from the manual for my gearbox. Hurth zf 5 HBW50

2.6 Connection of gearbox with

propeller

We recommend a flexible connection

between the gearbox and the propeller

shaft, when the engine is flexibly

mounted, in order to compensate for

angular deflections. The installation of a

special propeller thrust bearing is not

required, since the propeller thrust will

be taken by the transmission bearing,

provided the value specified under

«Technical data», item 1.2, is not exceeded.

However, the output shaft

should be protected from additional

loads. Special care should be taken to

prevent torsional vibration. When using

a universal joint shaft, make certain to

observe the manufacturer’s instructions.

First of all, I believe you enjoy relieving your self upon breakfast cereals. Did you ever work for Kellogg or C.W. Post? Curiosity. Where this obviously deep seated requisite may have initially sprung roots. Q. When you were a child, did anyone ever repeatedly urinate upon your porridge. Crap in your rice Krispy's or otherwise defile or disrupt your morning breaking of the fast?

Secondly, I do not eat Corn Flakes. I preferer to partake in rasinbran. Usually with fresh banana slices or other fruit. I always pour milk on the mixture... never urine.

Now, having gone off on a rant, it occurred to me that it is entirely possible that you may never take the Mickey Bliss on the give-and-go. And may merely be giving me a porkie. In any event, I would like to assume that you are attempting to provide constructive advice or instruction and not an attempt at animus.

Understanding that "the anima" is the personification of all female psychological tendencies in man, while the animus is the personification of all male psychological tendencies in woman. They form part of the collective unconscious, as archetypes or collectively inherited patterns of behavior, which are autonomous, making them particularly difficult to integrate into one’s personality. The integration of the shadow, or the realization of the personal unconscious, marks the first stage in Jungian psychology. I digress.

2.6 Connection of gearbox with

propeller

We recommend a flexible connection

between the gearbox and the propeller

shaft, when the engine is flexibly

mounted, in order to compensate for

angular deflections. The installation of a

special propeller thrust bearing is not

required, since the propeller thrust will

be taken by the transmission bearing,

provided the value specified under

«Technical data», item 1.2, is not exceeded.

However, the output shaft

should be protected from additional

loads. Special care should be taken to

prevent torsional vibration. When using

a universal joint shaft, make certain to

observe the manufacturer’s instructions.

"I hate to keep pissing on your corn flakes like this"...It is a pillow block.

First of all, I believe you enjoy relieving your self upon breakfast cereals. Did you ever work for Kellogg or C.W. Post? Curiosity. Where this obviously deep seated requisite may have initially sprung roots. Q. When you were a child, did anyone ever repeatedly urinate upon your porridge. Crap in your rice Krispy's or otherwise defile or disrupt your morning breaking of the fast?

Secondly, I do not eat Corn Flakes. I preferer to partake in rasinbran. Usually with fresh banana slices or other fruit. I always pour milk on the mixture... never urine.

Now, having gone off on a rant, it occurred to me that it is entirely possible that you may never take the Mickey Bliss on the give-and-go. And may merely be giving me a porkie. In any event, I would like to assume that you are attempting to provide constructive advice or instruction and not an attempt at animus.

Understanding that "the anima" is the personification of all female psychological tendencies in man, while the animus is the personification of all male psychological tendencies in woman. They form part of the collective unconscious, as archetypes or collectively inherited patterns of behavior, which are autonomous, making them particularly difficult to integrate into one’s personality. The integration of the shadow, or the realization of the personal unconscious, marks the first stage in Jungian psychology. I digress.

Interesting reading. So that's the max. axial load for your purchased bearing.

As long as your max. shaft thrust is less than :

3,147 lbs. X 0.25 = 787 lbs.

.......... you're in business. Not too sure what they refer to as the "properly applied locking mechanism" unless that's the two set screws on the bearing collar being installed into heavy dimples on the shaft. Set screws only applied to the shaft do not impress me for being able to resist axial forces. Any idea what your max. shaft thrust is ?

My solution to the above problem would be to use the largest bolts possible the pillow block will accept and then tighten the bejabbers out of them to eliminate the possibility of the block sliding sideways.

Yes I have seen that number somewhere in one of my files for this motor. The one I'm putting back in is a BMW bd7 which is a six to seven max horsepower motor. The transmission is rated to handle 5000 RPM the bd7 only puts out 35. I think it's somewhere around a two to one reduction. The limited spec sheet that I was able to find and send to you on the pillow bearing from the manufacturer stated that there are two dimples in the casing that you would drill through and put a sort of post in that would reduce or disallow the slop or radial agitation. I think I posted about my gearbox and they recommend a soft or flexible prop shaft and or connections. It certainly didn't have any when I bought it. That doesn't mean that the sailboat manufacturer cared to follow those instructions or suggestions. I think there's a lot of we've been doing it this way and been successful so we'll keep on doing it this way. I'm not a mechanical engineer but I did sleep in Holiday inn Express once. Seriously, I hung around with my grandfather a lot when I was a child he was a machinist an inventor, a mechanic and a carpenter. I think that a bit of my grandfather rubbed off on me. He was never afraid to tackle any project. And I had a front row seat for some of it. He used to tell me that problems were just a thing that would wait around for me to show up. Anyway if I mess up I'll learn something. Wasn't it Thomas Edison it said he didn't have failed experiments only that he had figured out hundreds of ways not to make a light bulb. I'll keep you all posted. I'm painting lettering and striping my above the water line.View attachment 219045

Interesting reading. So that's the max. axial load for your purchased bearing.

As long as your max. shaft thrust is less than :

3,147 lbs. X 0.25 = 787 lbs.

.......... you're in business. Not too sure what they refer to as the "properly applied locking mechanism" unless that's the two set screws on the bearing collar being installed into heavy dimples on the shaft. Set screws only applied to the shaft do not impress me for being able to resist axial forces. Any idea what your max. shaft thrust is ?

View attachment 219046

My solution to the above problem would be to use the largest bolts possible the pillow block will accept and then tighten the bejabbers out of them to eliminate the possibility of the block sliding sideways.

Back again.First of all, I believe you enjoy relieving your self upon breakfast cereals. Did you ever work for Kellogg or C.W. Post? Curiosity. Where this obviously deep seated requisite may have initially sprung roots. Q. When you were a child, did anyone ever repeatedly urinate upon your porridge. Crap in your rice Krispy's or otherwise defile or disrupt your morning breaking of the fast?

Egads

Absolutely not ! ! !And may merely be giving me a porkie.

Your approach to this problem has been logical every inch of the way. And for this, you are receiving constructive observations and criticism. The

that some people (mostly first timers) post on this site defies description. Idiots that have problems with their engines and so they look at their plumbing for the answer. People who come to this site with preconceived answers to their own question who proceed then proceed to tell everyone else they are wrong while not having a trace of common sense. The best way to get rid of these clowns is to ask them to provide a picture of the boat part in discussion. No bloody way and that's the end of the discussion. Too much work on their part.

that some people (mostly first timers) post on this site defies description. Idiots that have problems with their engines and so they look at their plumbing for the answer. People who come to this site with preconceived answers to their own question who proceed then proceed to tell everyone else they are wrong while not having a trace of common sense. The best way to get rid of these clowns is to ask them to provide a picture of the boat part in discussion. No bloody way and that's the end of the discussion. Too much work on their part.As @Tally Ho has said and I fully agree, you are pretty much re-inventing and complexifying (is that even a word) the small boat propulsion system BUT you are going about it in a correct manner, and me ? I'm just looking over your shoulder. I've never spent much time on bearing selection on the job but I've certainly learned more now than I even knew about bearings back then. Hell, this information was most unlikely unavailable back in my time when all bearings were made of iron wood and greased with tallow

I'll look at your motor(s) tomorrow and see if anything useful can be pulled out of there like max. tolerable thrust ?

Why do Brits call lies porkie?Back again.

Egads! I may never eat breakfast again after reading that colourful dissertation. I would have thought I would have had flashbacks back to my childhood had that ever happened. But I too digress.

Absolutely not ! ! !

Your approach to this problem has been logical every inch of the way. And for this, you are receiving constructive observations and criticism. Thethat some people (mostly first timers) post on this site defies description. Idiots that have problems with their engines and so they look at their plumbing for the answer. People who come to this site with preconceived answers to their own question who proceed then proceed to tell everyone else they are wrong while not having a trace of common sense. The best way to get rid of these clowns is to ask them to provide a picture of the boat part in discussion. No bloody way and that's the end of the discussion. Too much work on their part.

As @Tally Ho has said and I fully agree, you are pretty much re-inventing and complexifying (is that even a word) the small boat propulsion system BUT you are going about it in a correct manner, and me ? I'm just looking over your shoulder. I've never spent much time on bearing selection on the job but I've certainly learned more now than I even knew about bearings back then. Hell, this information was most unlikely unavailable back in my time when all bearings were made of iron wood and greased with tallow.

I'll look at your motor(s) tomorrow and see if anything useful can be pulled out of there like max. tolerable thrust ?

The Cockney population has a rhyme for all kinds of lies—or Porky Pies. This term dates back to the very beginning of Cockney slang around the mid-1850s and is also one of many terms still in use in present day England. Porky Pies stems from a British delicacy, the humble pork pie.

“You're telling me porkies.” Here, the two words are combined to create the word porkies. If someone tells you something you don't believe, let them know that you think they are telling porkies.

When someone arbitrarily gives me a little guff , I generally give a retort at length that requires at least considerable thought to decipher and possibly even some research. This usually makes them either come around or go away. In either case the Guff is restrained.

Good Lord man, I now understand your obsession with the the mechanical detail you are giving to your drive train. I just didn't put your name together on this posting with your first posting here way back in Feb. of this year. Your personal work in the restoration of your 1980 hunter 27 cherubini to date has been nothing less than incredible.

I've got to head out into the forest fire smoke around here today but will get back to your previous transmissions later if I don't get lost in the smoke.I have been reading posts for quite some time, I finally decided to join up. I own a 1980 hunter 27 cherubini. I am retired and have been living aboard. I just wanted to say hello.

LOL. I thought you were well aware. It's actually pretty funny Ralph. I'm literally laughing my ass off here.Good Lord man, I now understand your obsession with the the mechanical detail you are giving to your drive train. I just didn't put your name together on this posting with your first posting here way back in Feb. of this year. Your personal work in the restoration of your 1980 hunter 27 cherubini to date has been nothing less than incredible.

I've got to head out into the forest fire smoke around here today but will get back to your previous transmissions later if I don't get lost in the smoke.

Yeah it's because I thought that you were right along with me the whole time, is why I gave you the gas over the corn flakes deal. My back is angry at me again today for pushing it so hard doing the striping yesterday. My plans were to wet sand and clean them up, pinstripe them out and get a couple coats of clear on them. Don't know if my back is going to allow me to today. Got so much to do. Be safe with all that smoke and fire going on out there. My thoughts are with you all.LOL. I thought you were well aware. It's actually pretty funny Ralph. I'm literally laughing my ass off here.

Starting back at your post #52, you're going to have to do some translation for me starting with the BMW bd7 which seems like a model railroad engine. It's diesel I trust ? Isn't it a little underpowered for a Hunter 27 ?The one I'm putting back in is a BMW bd7 which is a six to seven max horsepower motor.

3500 I presume ?The transmission is rated to handle 5000 RPM the bd7 only puts out 35.

I've got ot make up a sketch of this. I had been concerned about the thrust on the transmission but I forgot that was the purpose of the thrust bearing to keep the transmission free from thrust.

Is this close enough to represent the basic concept ?

Do you have anything picked out for the universal joint and how are you doing for space for all of this equipment ?

Yeah I think you've hit it just about right. Although I'm thinking about using a CV joint instead of a U joint. There's a link to the BMW D7 motor I'm using: The BMW D7 Marine Engine: 4.5 kW (6 bhp). https://www.bmwmarine.com/media/d7_detail_info08.pdfStarting back at your post #52, you're going to have to do some translation for me starting with the BMW bd7 which seems like a model railroad engine. It's diesel I trust ? Isn't it a little underpowered for a Hunter 27 ?

3500 I presume ?

I've got ot make up a sketch of this. I had been concerned about the thrust on the transmission but I forgot that was the purpose of the thrust bearing to keep the transmission free from thrust.

Is this close enough to represent the basic concept ?

View attachment 219085

Do you have anything picked out for the universal joint and how are you doing for space for all of this equipment ?

I have purchased a u-joint here's a pic.

Attachments

-

261.2 KB Views: 107

That's a pretty cool program it appears that you make these graphic designs with. What program are you using if you don't mind I ask? And yes space is tight when I get my flexible shaft seal in then I'll know what I've got. I am flying by the seat of my pants at this moment. But that's pretty much my usual. If I add much more to the shaft system I won't have to move my engine I can just hook it up right there in the salon.