Hello from Toronto,

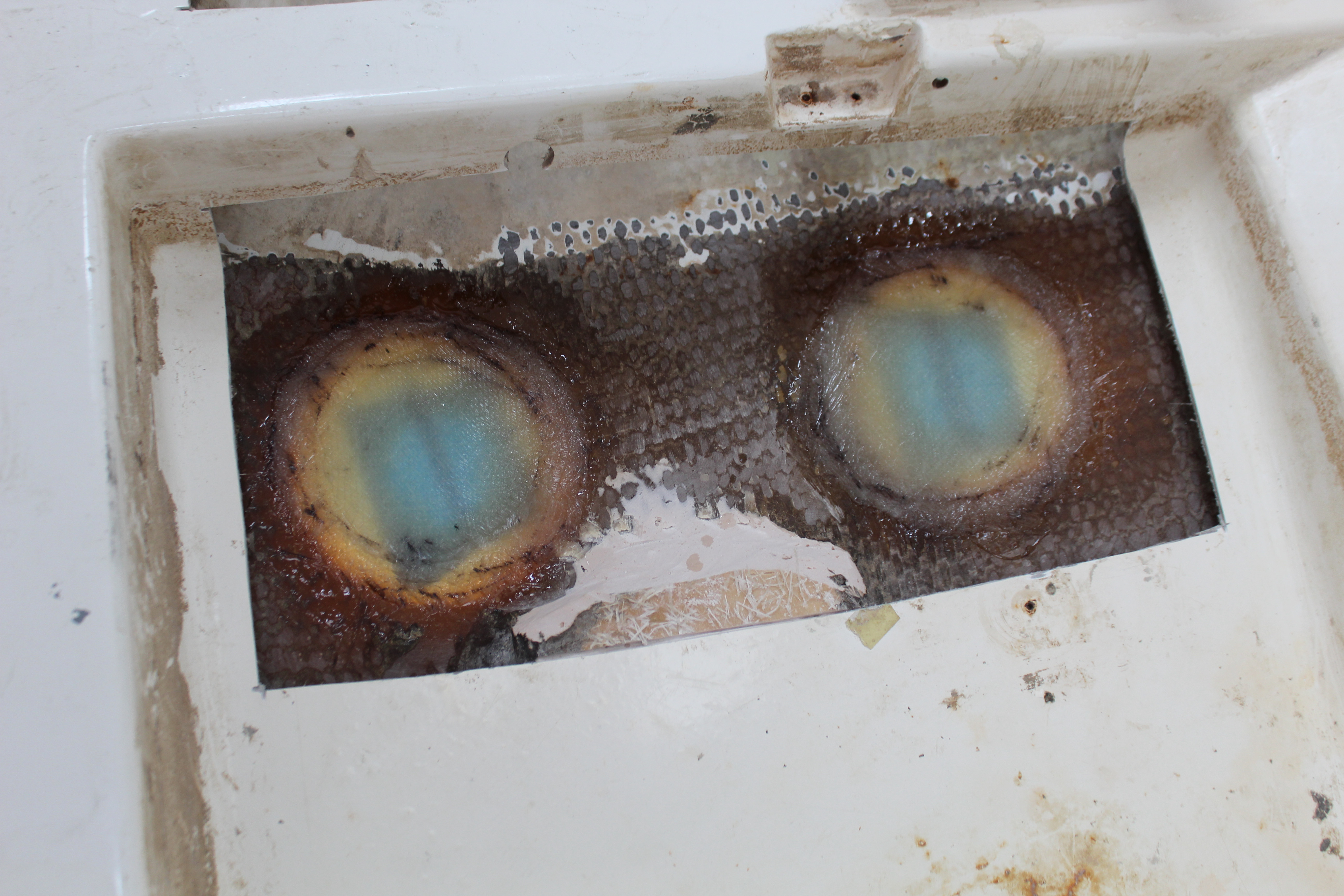

I also have a 1985 Hunter 40 and have been following your repair work. I have a question with regard to your keel /haul joint. Looking at the bow, image above, just behind your repair of the 2 thru hauls, on the outside. The 2 lead pods, which are part of the keel design, on port and starboard, approiximately 10 inches apart, , as I call them are showing signs of rust, i'm sure the other 2 at rear are in the same condition , along with the whole joint, mine is also showing the same signs of rust. Most of the rust accumulates at the bootom of the sump/keel attachment after the boat is hauled out, this being the lowest part of haul keel joint, water will flow to lowest point.

How will you repair the rust area.

Hunter used a product to seal the gap orignally, i believe similar to 3m 5200

I going to proceed by first sanding out the area, down to iron on one side, and gelcoat on the other side, 2" on each side, then cut out a v groove in the joint and then applying petis rust lock, 3m 5200, interlude 200 expoxy,then gflex, then anti fouling paint.

The other option is to drop keel, and proceed as this owner did,

Well its been a long time since my last blog but the dream is still alive and the projects have been continuing on Zingara. The big project...

myzingara.blogspot.com

.

The keels bolts have been torqued to hunter specs, all went well, nothing broke on mine. No rust or water in the bilge when boat in water,

I belive this keel/haul joint design to be one of the best, spreading out stress through haul strength.

Looking forward to your answer, excuse my fragmented explanation, reading too many ikea instructions

Thank you

Paul

Emerald II