Parting out H170 in AZ

- Thread starter Mik

- Start date

"Thinking Chair".BTW that’s a pretty comfy looking captains chair in the bow!!!

So that’s the infamous thinking chair."Thinking Chair".. I'm tempted to actually take it out some day and enjoy the quarreling for who gets to use it.

Today is News(Good | Bad) day.

Got the port side bench all sanded down and faired in. When all edges are ready, i will glue those in. At least i can sit on the benches without glass bits running me through.

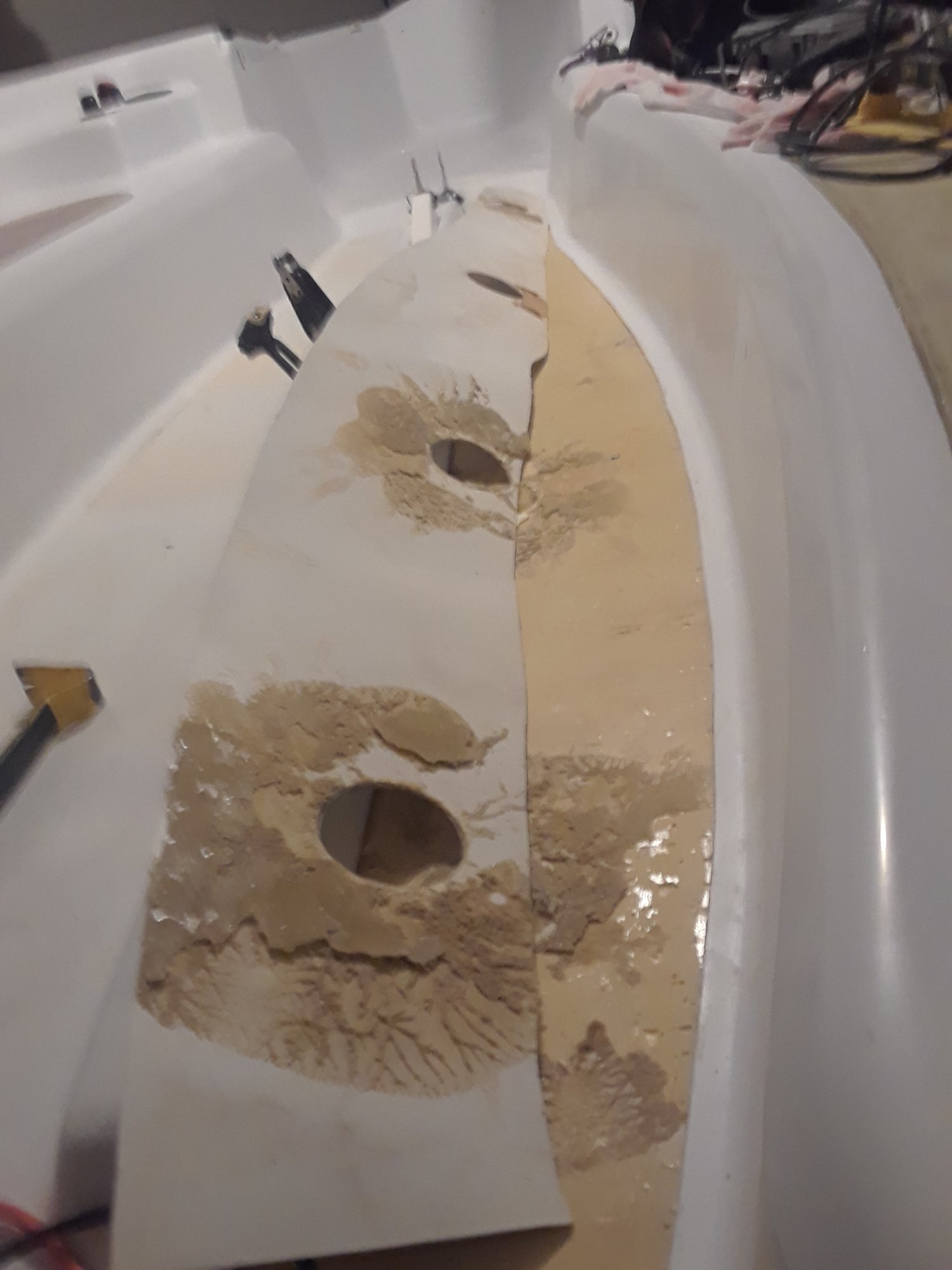

Starting on the floor. Starboard panel has been removed. That was a mess. The luran is just floating over the foam core. Where i glued the pucks down it was permanent. It took some agressive crow bar action to get all the luran off. Its easy here to see what it looks like when 4" pucks are cut off and glue is spread around. Check out the massive glue coverage versus the port side bench with tiny gorilla glue sqirts. The glued pucks took some foam with them as well. Seriously, if you need to fix delamination, cut five four inch pucks per square

foot, you will get 100% coverage. Still have 100% confidence in PL3X, but any 5200 would work great too.

With the luran off, i see there are more challenges ahead.

The deck between the centerboad and the mainsheet swivel is floating. I didnt support this area when i did the others since it felt more solid . With the luran gone its obviously needing support.

. With the luran gone its obviously needing support.

Right next to the puck (very well attached here) is a block of plywood embedded in the foam. I suspect Hunter had that wood epoxied to the centerboard housing. The epoxy is still there, the pkywood delaminated. One layer of plywood is still attached to the luran, and some epoxy is on the sidewall. The core deck moves up and down about and inch each way. I could fix this with a foam piller, but my mind is going a mile a minute with ideas.

I wanted to leave the center foot stop since that area is clearly the strongest part of the boat, but...I think it would be a better repair to simply cut the whole deck off. Once the deck is rebuilt i could use the luran foot stop as a 2part foam mold. The area near the centerboard will be a bear. I may have to grind the luran off that area.

So I'm removing the mainsheet swival and the mast step. The pin for the swivel is bent, so ill make a stop by WM to get a replacement. I'm thinking, that mast step is going to need a philips extenstion since its on so tight and in a deep confined space. Nope, finger tight. The wood under the mast step is rotten, I could smell the moist wood as soon as I pulled the screws out. So all the luran on the deck is getting removed, including the central foot stop. I'm thinking I either get some thin plywood and bond it to the foam, or actually say f it, cut out the foam too and make a new foam floor with real foam stringers glassed in.

Its not too hard pulling the centerboard out.

Got the port side bench all sanded down and faired in. When all edges are ready, i will glue those in. At least i can sit on the benches without glass bits running me through.

Starting on the floor. Starboard panel has been removed. That was a mess. The luran is just floating over the foam core. Where i glued the pucks down it was permanent. It took some agressive crow bar action to get all the luran off. Its easy here to see what it looks like when 4" pucks are cut off and glue is spread around. Check out the massive glue coverage versus the port side bench with tiny gorilla glue sqirts. The glued pucks took some foam with them as well. Seriously, if you need to fix delamination, cut five four inch pucks per square

foot, you will get 100% coverage. Still have 100% confidence in PL3X, but any 5200 would work great too.

With the luran off, i see there are more challenges ahead.

The deck between the centerboad and the mainsheet swivel is floating. I didnt support this area when i did the others since it felt more solid

Right next to the puck (very well attached here) is a block of plywood embedded in the foam. I suspect Hunter had that wood epoxied to the centerboard housing. The epoxy is still there, the pkywood delaminated. One layer of plywood is still attached to the luran, and some epoxy is on the sidewall. The core deck moves up and down about and inch each way. I could fix this with a foam piller, but my mind is going a mile a minute with ideas.

I wanted to leave the center foot stop since that area is clearly the strongest part of the boat, but...I think it would be a better repair to simply cut the whole deck off. Once the deck is rebuilt i could use the luran foot stop as a 2part foam mold. The area near the centerboard will be a bear. I may have to grind the luran off that area.

So I'm removing the mainsheet swival and the mast step. The pin for the swivel is bent, so ill make a stop by WM to get a replacement. I'm thinking, that mast step is going to need a philips extenstion since its on so tight and in a deep confined space. Nope, finger tight. The wood under the mast step is rotten, I could smell the moist wood as soon as I pulled the screws out. So all the luran on the deck is getting removed, including the central foot stop. I'm thinking I either get some thin plywood and bond it to the foam, or actually say f it, cut out the foam too and make a new foam floor with real foam stringers glassed in.

Its not too hard pulling the centerboard out.

Last edited:

Wow that looks like the areas you fixed were REALLY stuck down!

Lots to consider here, I’m sure the chair is getting a good workout.

When you mention removing the foam I’m not sure if you mean all of it down to the FRP layer or just some slots where you could insert stringers.

In post #96 Parting out H170 in AZ

you show the foam pucks. If you remove all of the foam would you risk the “top” of the puck column delaminating from the

FRP layer?

Lots to consider here, I’m sure the chair is getting a good workout.

When you mention removing the foam I’m not sure if you mean all of it down to the FRP layer or just some slots where you could insert stringers.

In post #96 Parting out H170 in AZ

you show the foam pucks. If you remove all of the foam would you risk the “top” of the puck column delaminating from the

FRP layer?

Its a worse case scenario but needs to be considered...take a saws all and cut completly through the foam and the stitch matt. When its done, there will be a huge opening where one could stand in the hull and see the centerboard casing coming up. Leave just enough foam to reconnect a replacement. This would mean removing the foam columns as well and replacing with lighter and stronger grp foam core stringers. The deck coring is fine, just needs support so likely will not saws all the floor. If I do you can be sure i show pictures afterwards.Wow that looks like the areas you fixed were REALLY stuck down!

Lots to consider here, I’m sure the chair is getting a good workout.

When you mention removing the foam I’m not sure if you mean all of it down to the FRP layer or just some slots where you could insert stringers.

In post #96 Parting out H170 in AZ

you show the foam pucks. If you remove all of the foam would you risk the “top” of the puck column delaminating from the

FRP layer?

If i remove the foot stop i think i will be able to figure out how to support the deck around the centerboard case.

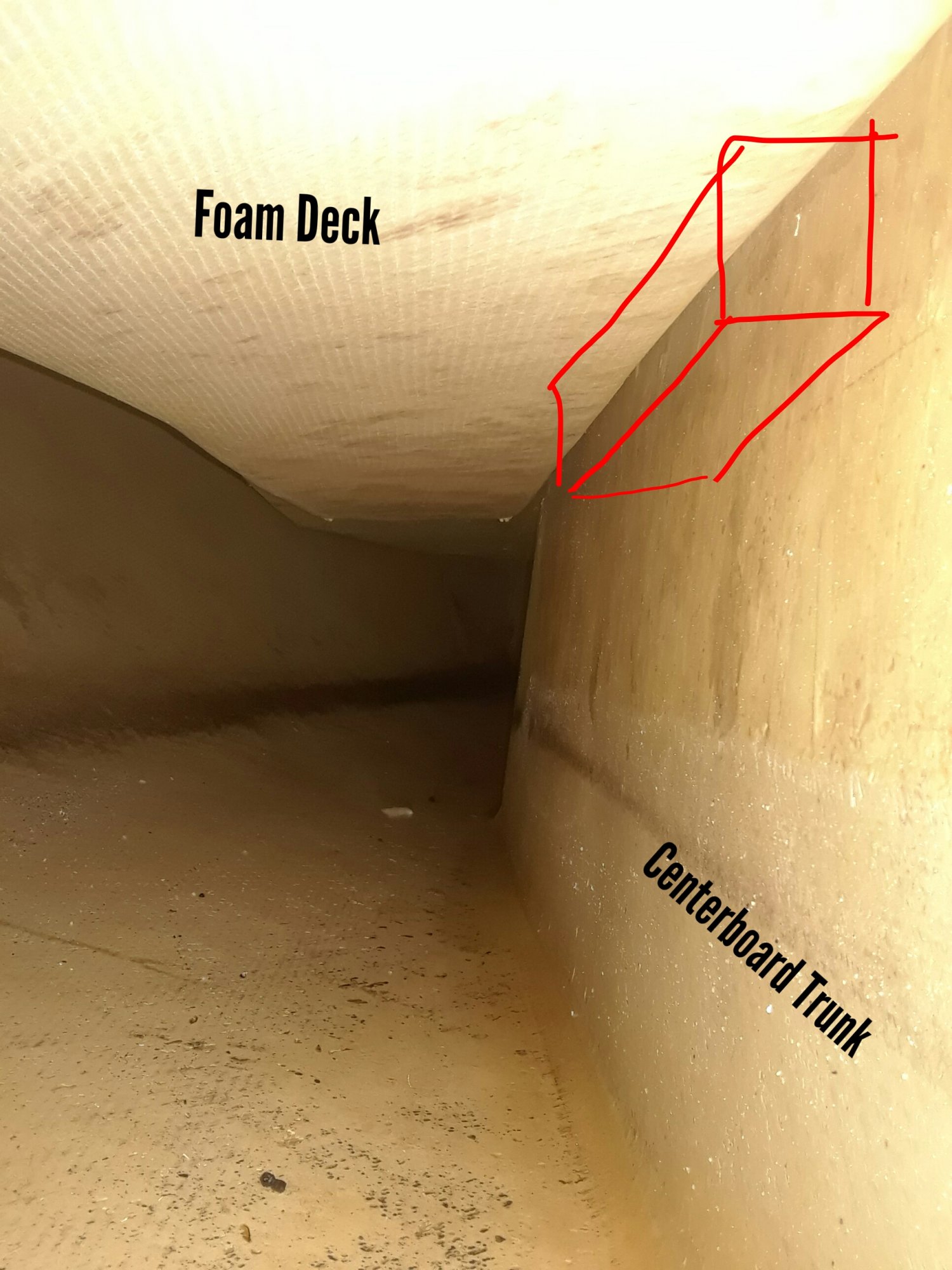

I will consider myself lucky. The port side deck is gone. The deck on the other side is equally messed up and sinking down about 3/4 inch. There is a rotten wood piece there as well. I have no clue, no clue what problem those bits solve. The deck is completly free floating, by design, completly around the centerboard trunck.

The center foot stop is not going away. I made a mediocre effort to crowbar it off and it just twist and flexes, but does not pull off whatever it is glued to. Good, ill use it to give the foam something to stick to.

The sweet glass repair i did to fix the crack earlier is gone. It took some serious crowbar activity time to pull that off the foam. I cant tell where the crack on the foot stop is anymore, even with me trying to crowbar the stop off. Not impressed with the home depot fiberglass cloth. Stick with stitch matt if you can. The crowbar split the GRP lamination at a layer that didnt absorb enough expoxy. Thats not happening with the new layup. Had to pause to study a fantastic hologram effect on the luran that was well attached to the GRP. Looked like it was about 1 inch of clear GRP, but was really one layer of lightweight weave.

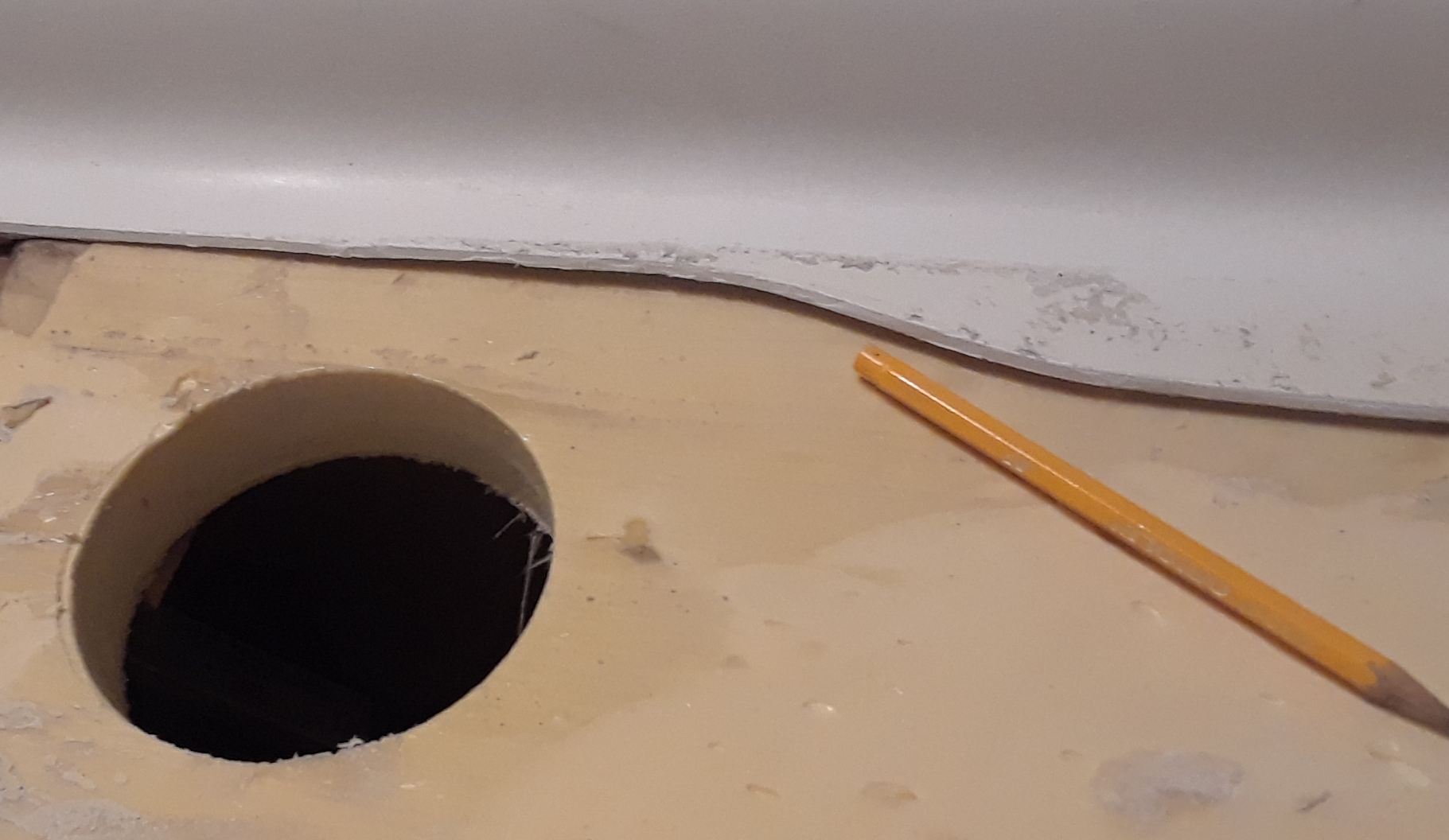

The foam deck is in good condition so no saws all action. Thinking about lifting the deck with a crane to level it with the foot stop, then epoxying a shelf to the centerboard trunk. That should support the deck and still let it "float".

Already have recalled tbe 4" hole saw back to active duty.

The colums are doing great.

The center foot stop is not going away. I made a mediocre effort to crowbar it off and it just twist and flexes, but does not pull off whatever it is glued to. Good, ill use it to give the foam something to stick to.

The sweet glass repair i did to fix the crack earlier is gone. It took some serious crowbar activity time to pull that off the foam. I cant tell where the crack on the foot stop is anymore, even with me trying to crowbar the stop off. Not impressed with the home depot fiberglass cloth. Stick with stitch matt if you can. The crowbar split the GRP lamination at a layer that didnt absorb enough expoxy. Thats not happening with the new layup. Had to pause to study a fantastic hologram effect on the luran that was well attached to the GRP. Looked like it was about 1 inch of clear GRP, but was really one layer of lightweight weave.

The foam deck is in good condition so no saws all action. Thinking about lifting the deck with a crane to level it with the foot stop, then epoxying a shelf to the centerboard trunk. That should support the deck and still let it "float".

Already have recalled tbe 4" hole saw back to active duty.

The colums are doing great.

Attachments

-

247.7 KB Views: 476

-

268.8 KB Views: 521

Last edited:

Random thought on your process to get it to the height you want.. could you place wedges or jacks between the “inside’ of the bottom of the boat and the “bottom” of that surface to “lift” it?

As you know Hunter typically inserted wood in places to let them use screws to attach stuff, could that be why this wood is there?

Not that it’s funny, you struggling to get your previous fixes apart (well maybe a little ) but that's the price you pay for doing things properly. I worked a lot with my Dad and he was fond of using extra nails when he built something, fun driving them in, not so much taking it apart later.

) but that's the price you pay for doing things properly. I worked a lot with my Dad and he was fond of using extra nails when he built something, fun driving them in, not so much taking it apart later.

As you know Hunter typically inserted wood in places to let them use screws to attach stuff, could that be why this wood is there?

Not that it’s funny, you struggling to get your previous fixes apart (well maybe a little

I like the wedge idea, the problem with lifting the deck up with a crane is i use the 4" holes for the "hook". I then dont have enough room to add the shelf support, also risky sticking my arm in the hole with the tension. If i can get the wedges in there ill have room to work, then remove the wedge supports afterwards.

It was interesting scraping off the luran with GRP attached to it. I got the port side off on one piece, which was surprising.

The luran is soft, pliable, and cuts like butter with a dremel. The GRP is none of those. The luran came off like a bad sunburn all warped, but whole, the small GRP section cracked and splintered, destroyed, held together with the weave of the cloth. The GRP removed, took core foam with it.

When hunter bragged about the durability of luran they were talking about it not shattering on impact, but GRP is much more stable.

Hiking straps...those blocks can only be for hiking straps...unless you want to back flip off the side like a seal diver when the screws in rotten wood give out.

It was interesting scraping off the luran with GRP attached to it. I got the port side off on one piece, which was surprising.

The luran is soft, pliable, and cuts like butter with a dremel. The GRP is none of those. The luran came off like a bad sunburn all warped, but whole, the small GRP section cracked and splintered, destroyed, held together with the weave of the cloth. The GRP removed, took core foam with it.

When hunter bragged about the durability of luran they were talking about it not shattering on impact, but GRP is much more stable.

Hiking straps...those blocks can only be for hiking straps...unless you want to back flip off the side like a seal diver when the screws in rotten wood give out.

Last edited:

Could you place two small (fit through the 4" hole) bottle jacks at either end of a length of 2X4 or something stiff to lift the foam to level, place your temp wedges and then carry on. The two jacks would let you adjust for the curve of the bottom etc. so you get the foam exactly where you want.

I also was wondering if the foam "pillars" you installed will restrict your ability to lift the foam up?

Yes I think the Luran is pretty "puncture" proof but by no means overall tuff. I had our boat at a dock at a marina for about a month and notice where the fender was between the hull and dock now isn't as shiny as the rest of the side of the boat. Good quality fender so I'm thinking the Luran scuffed a bit. That wouldn't happen on a glass boat!

I also was wondering if the foam "pillars" you installed will restrict your ability to lift the foam up?

Yes I think the Luran is pretty "puncture" proof but by no means overall tuff. I had our boat at a dock at a marina for about a month and notice where the fender was between the hull and dock now isn't as shiny as the rest of the side of the boat. Good quality fender so I'm thinking the Luran scuffed a bit. That wouldn't happen on a glass boat!

I’m thinking you use the jack to get the foam in place as it’s infinitely adjustable in very small increments. The wedge goes in to hold that section up while you move the jack.

Once you have the entire area lifted and wedged you place your permanent “brace”. Once that sets up you remove the wedges.

Once you have the entire area lifted and wedged you place your permanent “brace”. Once that sets up you remove the wedges.

Started cleaning up the foam. Pulled out a scissor jack from my car and lifted the deck. That should work nice. The gap closes right up.

I need to see if i can get any foam that i can glass up for a brace. Also need to look for a lightweight filler for the foam. The west system light density is too expensive to slather over the foam.

As the jack is lifting the floor the perimeter luran can be glued down. Going to be a busy weekend.

I need to see if i can get any foam that i can glass up for a brace. Also need to look for a lightweight filler for the foam. The west system light density is too expensive to slather over the foam.

As the jack is lifting the floor the perimeter luran can be glued down. Going to be a busy weekend.

What about this stuff for the brace? Home Depot or scraps from construction site for freeI need to see if i can get any foam that i can glass up for a brace.

Just don’t get a flat tire on the way there!

Which Dremel tool did you use to cut with?The luran is soft, pliable, and cuts like butter with a dremel.

Model 395 type 5 with a heavy duty cut off wheel. Ive used the same wheel for this entire project. Usually, the cut off wheel wears down or they break as i put the tool down. A larger grinder would have been more efficient.Which Dremel tool did you use to cut with?

I feel like ill tear a hole in the space time continuum if i dial it more than 4, but 3 was a good compromise between time cutting and starting a fire or melting luran. The heat does distort the luran so more cutting is better than turning your cutting tool into a broco rod.

Last edited:

That’s good info to have documented for anyone who might choose to do this type of repair. I wonder if a skill saw with a fine toothed blade would work. You mentioned getting hit with some hot slag that the blade housing of the saw would prevent.

Came close. The yellow foam with foil would be the only product in home depot..polyiso foam. safe for polyester resin and epoxy. I didnt need alot so i was thinking of driving by a couple boat repar facilites for scraps.What about this stuff for the brace? Home Depot or scraps from construction site for free

View attachment 170716

Just don’t get a flat tire on the way there!

I had some extra foam in a can for the rudder mount repair so went all redneck and what not.

I turn loctite high-density spray foam, pop-tart box, and 1700 biaxial stitch matt into new deck support braces.

That foam is junk so i cant recommend it, but its good enough for this application. 6lb density 2-part foam should aways be laying around a boat owners home.

The braces look third-party, but they are only 3oz each and are very robust. They will be epoxied to the centerboard trunck and the deck will rest on the large flat top area.

Attachments

-

422.7 KB Views: 487

-

319.8 KB Views: 457

-

422.5 KB Views: 445

If i had a tiny handheld skill saw i would try it. I have never tried those oscillating cutters. Those might work. Jig saw would be the worst choice. You dont want the luran getting pulled up up.That’s good info to have documented for anyone who might choose to do this type of repair. I wonder if a skill saw with a fine toothed blade would work. You mentioned getting hit with some hot slag that the blade housing of the saw would prevent.