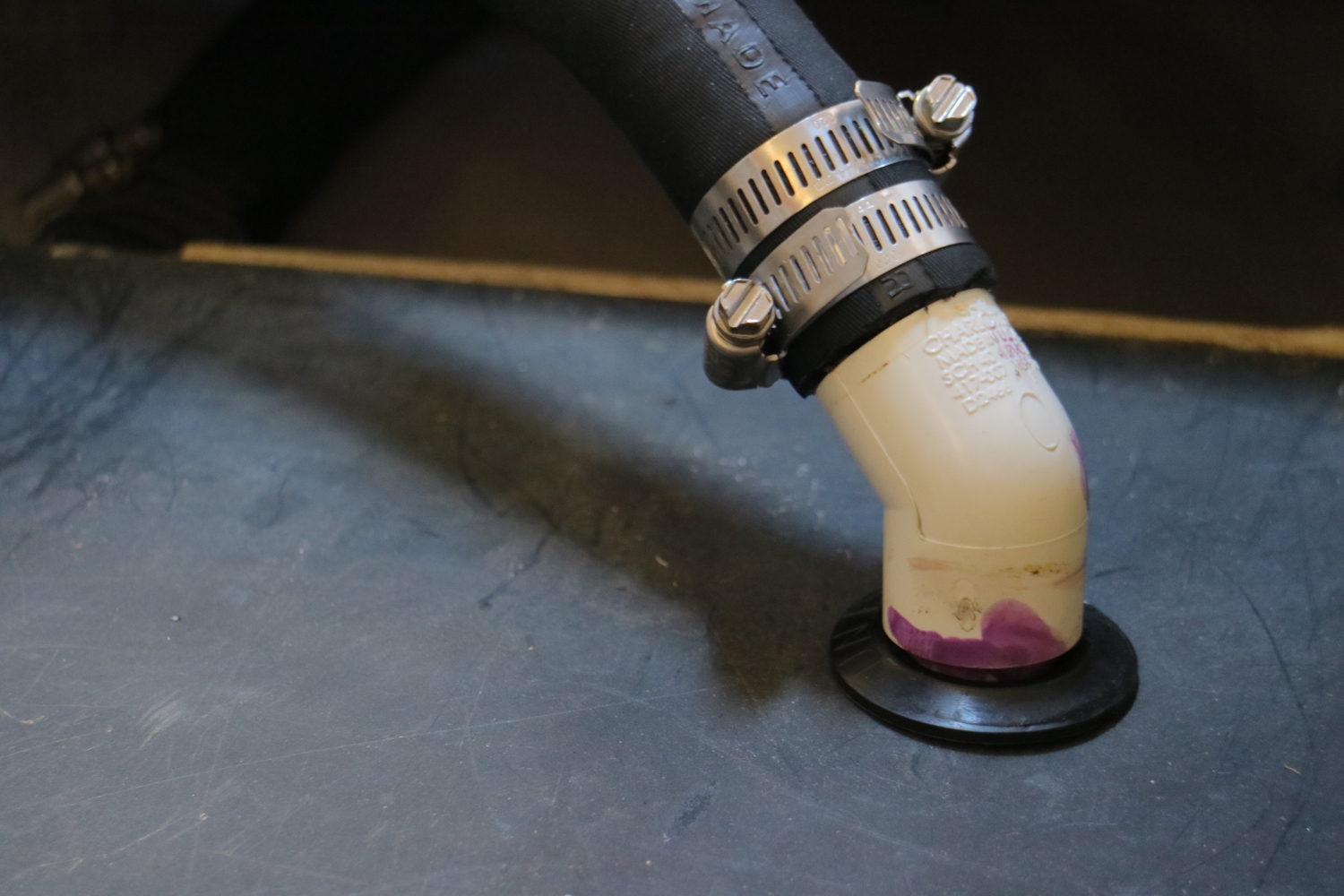

I am going to reroute the vent for the ware and water tanks to a mushroom vent located just belie the toe rail.

My question is where to locate the vent. It is currently located above the head and locker.

When I look at this locations there are several screws below the toe rail that suggest that there is some sort of reinforcement there. Can’t prove it.

Anyone know if there is?

Should I never the hoses toward the stern and go through the small storage cabinets to the stern side of the bulkheads?

Any opinions?

Steve Goldman

Peenhonin

1985 Catalina 30 TRBS

Waukegan, IL

My question is where to locate the vent. It is currently located above the head and locker.

When I look at this locations there are several screws below the toe rail that suggest that there is some sort of reinforcement there. Can’t prove it.

Anyone know if there is?

Should I never the hoses toward the stern and go through the small storage cabinets to the stern side of the bulkheads?

Any opinions?

Steve Goldman

Peenhonin

1985 Catalina 30 TRBS

Waukegan, IL