suddenly I found myself done with all of the BIG projects that take up days on end. I stumbled for a few days completely overwhelmed with all of the small tasks remaining. I finally put it all down on paper (well, excel) and prioritized. it was then that I realized that I am ready for the keel but the keel is not ready! so back to the keel it is! I put down a layer of 1708 along the leading edge (I intentionally left the leading edge of the profile low for this reason) in a attempt to help reduce any damage caused by hitting something under water. in hindsight, I should have done the same on the bottom, but I didn't.

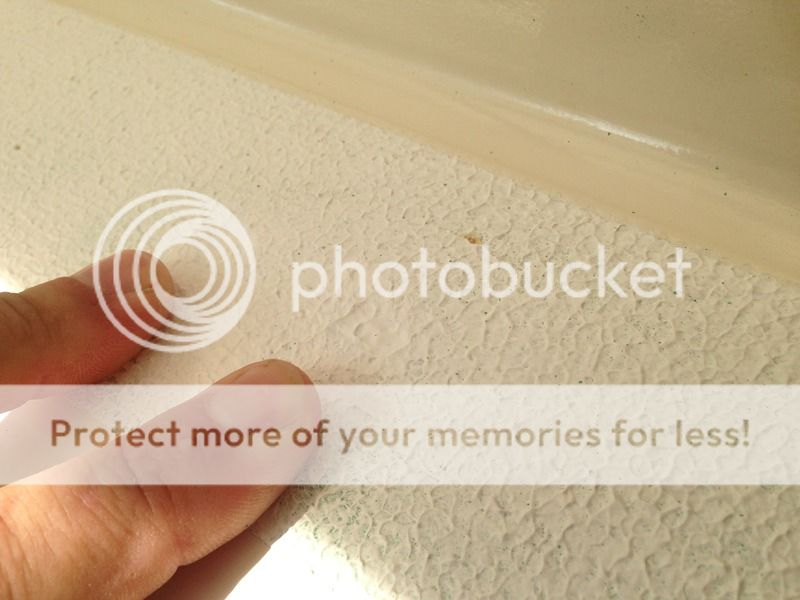

since I decided to ditch the factory nylon 2 bolt cleats and go with some hereshoff style stainless cleats I had to fill the holes. unfortunately I didn't decide this until after paint a kiwigrip. then I realized that this would be a good test of how easy both the paint (foreward cleats) and kiwigrip (aft cleats) would be to touchup. needless to say, I will be ALOT less concerned about bumps now. here is the touched up area, note that it is not where the cleat is in the pic but the area to the left where the kiwi grip is (its filthy from sanding dust, excuse the mess)

and here I am pointing to where the two holes are. not too bad for my first repair attempt, as least I think

I don't have pics of the bow repair yet, it is still being painted.

I also worked on the sliding hatch as well as the other hatch. got them sanded and first coat of paint.