Whats the opinion on the structural soundness of fixing the top this way? Reason being I have a houseboat with an overhang that did not get sealed properly when removing the rails. The screw holes let water into the plywood causing decay. The area will never see any weight on it. It would sure be so much easier to clean out the area and fill with thickened epoxy and some mat instead of cutting the section out and replacing it.

when something little turns in to something more

- Thread starter hawk232

- Start date

I would use foam wherever possible. Thickened epoxy will be heavy, you'd be surprised how much volume that is. Even for structurally loaded areas, high density foam core remains light but still has excellent compressive strength while being easy to cut, shape, and bend.

Whats the opinion on the structural soundness of fixing the top this way? Reason being I have a houseboat with an overhang that did not get sealed properly when removing the rails. The screw holes let water into the plywood causing decay. The area will never see any weight on it. It would sure be so much easier to clean out the area and fill with thickened epoxy and some mat instead of cutting the section out and replacing it.

if I had your kind of money I would order up a bunch of $50-$75 foam for this small area as well!! in reality, this is a budget build where I am using materials I have on hand ( I do have 4 sheets of coosa but that's for another project) I will be sure to pay attention to how much filler I use there and weigh it up so that we will know...

hillbilly- in my situation it should be stronger than stock. 1/4" of fiberglass is stronger and lighter than 1/4" of wood that it is replacing. I am also planning to fill the space where the mast step is with actual fiberglass, not just thickened epoxy that will be IMMENSELY stronger than the peanut butter that was under it before. now, all of that being said, it doesn't need to be done that way... it lasted the way it was for 40 years!!!

hillbilly- in my situation it should be stronger than stock. 1/4" of fiberglass is stronger and lighter than 1/4" of wood that it is replacing. I am also planning to fill the space where the mast step is with actual fiberglass, not just thickened epoxy that will be IMMENSELY stronger than the peanut butter that was under it before. now, all of that being said, it doesn't need to be done that way... it lasted the way it was for 40 years!!!

I didn't mean to imply you should throw money at it, believe me I'm all about using materials on hand. I mentioned the foam directly related to Hillbilly's comment about the overhang on his houseboat. Divincell foam costs more than gold by weight, but I've heard (never tried it) that DOW Blue Core and Owens Corning Pink foam board are great alternatives. The compressive and/or sheer strength might not be as high as Divincell and such, but they still still have excellent core properties that are just fine for decks and overheads. The 1/8th sheets are easy to work with and make the light curves for decks.

I am for sure not made of money... this last year has been really rough. In 2013 I was laid off from my job in the solar energy sector and then went to work for the DoD at 1/2 of my previous salary, almost losing my house on the way. Right now I'm scratching and clawing my way back up to where I need to be financially. I've given up many things (like bike racing) to be able to spend the money where I need it on my restoration project. Putting in the work with my hands is the only thing keeping me sane right now, lol!

I am for sure not made of money... this last year has been really rough. In 2013 I was laid off from my job in the solar energy sector and then went to work for the DoD at 1/2 of my previous salary, almost losing my house on the way. Right now I'm scratching and clawing my way back up to where I need to be financially. I've given up many things (like bike racing) to be able to spend the money where I need it on my restoration project. Putting in the work with my hands is the only thing keeping me sane right now, lol!

if I had your kind of money I would order up a bunch of $50-$75 foam for this small area as well!! in reality, this is a budget build where I am using materials I have on hand ( I do have 4 sheets of coosa but that's for another project) I will be sure to pay attention to how much filler I use there and weigh it up so that we will know...

hillbilly- in my situation it should be stronger than stock. 1/4" of fiberglass is stronger and lighter than 1/4" of wood that it is replacing. I am also planning to fill the space where the mast step is with actual fiberglass, not just thickened epoxy that will be IMMENSELY stronger than the peanut butter that was under it before. now, all of that being said, it doesn't need to be done that way... it lasted the way it was for 40 years!!!

For what it worth, I've used the blue construction foam in the past to make an epoxy composite support frame on a sailboat that required some extensive structural repaire. I cut out the foam, shaped it, then covered it with several layers of fiberglass cloth saturated with WEST epoxy,(of course :dance , and epoxied it into the hull. Actually pretty simple, and extremely strong.

, and epoxied it into the hull. Actually pretty simple, and extremely strong.

Don

Don

using that foam to "mold" a shape out of fiberglass works very well. it should be noted though that (unlike core-cell foams) the foam itself provides little to no strength. if your layup is relying on the core for strength you should look elsewhere, if you use enough mat to provide ALL of the strength the foam is an EXCELLENT shape holder!

Why even bother with putting skins back on? You have the top sealed in fiberglass and I am sure you are painting the surface. Might be a stupid question but I was curious.

that is a VERY good question, and honestly, I hadn't considered just making new skins. in thinking about it throughout the day, I started off planning to build new skins. then I remembered that this fiberglass is supposed to be for my speedboat project. it would take 4-5 more layers of glass to build a new skin. I think I am going to be a cheapskate with my biax and just re-use the skins...

thanks for the suggestion and honestly building all new skins at the same time as laminating the rest would result in a stronger end result.

thanks for the suggestion and honestly building all new skins at the same time as laminating the rest would result in a stronger end result.

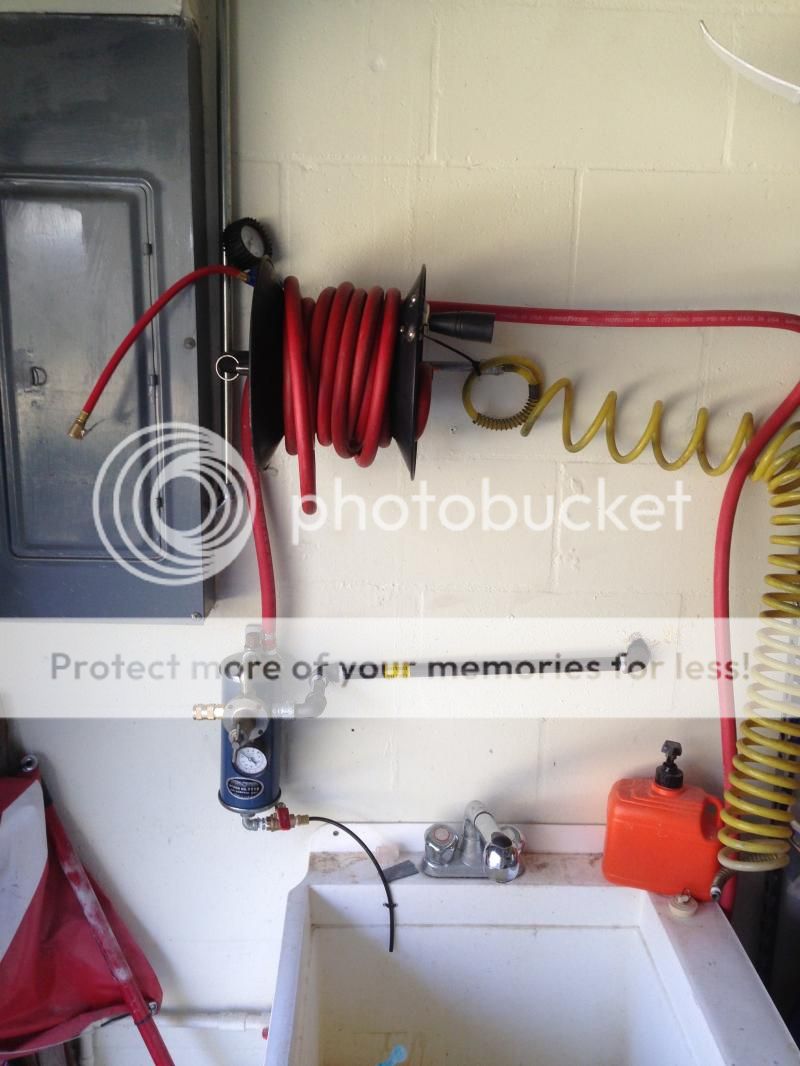

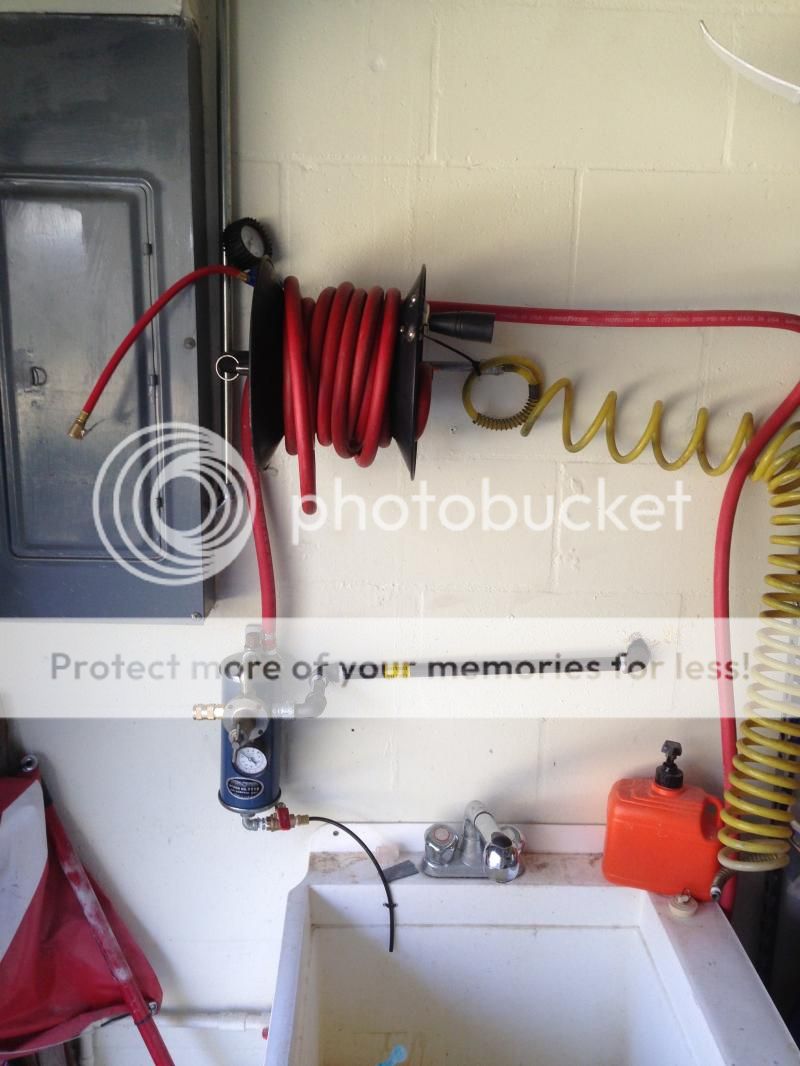

yesterday we had guests so I worked in the yard in the morning and finished up running air lines in the afternoon

then this morning I finished sanding down the old skins, cut out two more layers of mat then got to work mocking things up:

then took it all apart and coated each of my "filler" wood pieces with resin

then I started laminating (pic was taken after second layer, there are 4 layers total with an additional 5 (done beofe the bigger pieces) for the mast step)

then weight it all down and wait...

ok, so maybe not really wait. after I did that I sanded down the keel and put on a coat of thickened epoxy (the first thickened coat on the second side) no pics of that though

then this morning I finished sanding down the old skins, cut out two more layers of mat then got to work mocking things up:

then took it all apart and coated each of my "filler" wood pieces with resin

then I started laminating (pic was taken after second layer, there are 4 layers total with an additional 5 (done beofe the bigger pieces) for the mast step)

then weight it all down and wait...

ok, so maybe not really wait. after I did that I sanded down the keel and put on a coat of thickened epoxy (the first thickened coat on the second side) no pics of that though

well today I decided to move on to the cockpit floor. I had some soft spots that I was confident were either rotten or beginning to rot. the odd thing was that when I looked underneath the cockpit floor from inside the lazerette, all of the wood looked fine. here is why. it seems that the factory put down some thickened resin to bond the cockpit sole to the wood core, well evidently they did a poor job on my boat and left some voids, no rotten (or even wet) wood to be found

then I started working on removing the windows and chainplates. I don't know why but for some reason it didn't feel "real" until I removed these items. it was nasty weather today so glassing it all back together was out of the picture

then I sanded the stbd cabin top and part of the stbd hull side

then I started working on removing the windows and chainplates. I don't know why but for some reason it didn't feel "real" until I removed these items. it was nasty weather today so glassing it all back together was out of the picture

then I sanded the stbd cabin top and part of the stbd hull side

I think one of the reasons C22's continue to remain so popular is the amount of care we give to our boats that would otherwise be candidates for a scuba park underwater feature. Not saying anything bad about yours, this is meant as a commendation for a fellow boat restorer! After all, when you put in the kind of time and effort it takes to bring something back to a thing of beauty, you cannot deny the attachment felt towards it!

I can't wait to see what it will be like once we get our boat launched.

Keep up the good work, it will pay off with all the heads that will turn when she's done!

I can't wait to see what it will be like once we get our boat launched.

Keep up the good work, it will pay off with all the heads that will turn when she's done!

poor boat has just been sitting!! I was building a chicken coop all weekend and it was raining today. I did plan to work on the boat some but gene decided to prevent that! he hung around just long enough so that it wasn't worth me getting covered in fiberglass, then he left!!

I did just order a raymarine st2000+ though and just finished reading Don Guillette's Sail Trim Guide, at least I am of the sailing mindset, does that count??

I did just order a raymarine st2000+ though and just finished reading Don Guillette's Sail Trim Guide, at least I am of the sailing mindset, does that count??

All the work you've been doing getting her back in shape, you deserve a day off. By the way, you'll LOVE the ST2000. It's an overkill, but with the faster reaction time over the ST1000, you'll not regret it. It will turn into almost your favorite Mate. I couldn't think of sailing without ours.

Don

Don

Thanks Don! You are partially to blame, I seem to recall several threads where you stated that you could not imagine not having yours.

Today I did a lot of sanding on the cabintop to get it smooth in prep for fairing. I also countersunk all of my inboard genoa track holes so that I can fill them also. I want to move the track further aft and I want to bend it slightly to match the curve of the cabin.

I also cut the holes for my cockpit drains. now I just need some fiberglassing weather!!!

Today I did a lot of sanding on the cabintop to get it smooth in prep for fairing. I also countersunk all of my inboard genoa track holes so that I can fill them also. I want to move the track further aft and I want to bend it slightly to match the curve of the cabin.

I also cut the holes for my cockpit drains. now I just need some fiberglassing weather!!!

I wish I were rich like you two! My auto tiller is a dock line stretched across the cockpit with a sail tie wrapping it to the tiller.

It works okay, but no one makes a remote control for it yet.

It works okay, but no one makes a remote control for it yet.

you do too, in fact, have a remote control!!! "Hey Carlotta, fall off a bit would you?" Man, yours is even voice command!!!I wish I were rich like you two! My auto tiller is a dock line stretched across the cockpit with a sail tie wrapping it to the tiller.

It works okay, but no one makes a remote control for it yet.

Don't tell her I said that... ill be in trouble!! :X

in case anyone is interested, I finished the scuppers

then I made a new spacer for my mast step (the PO used a piece of wood that was deteriorating at this stage, so I used starboard)

then through today I have been sanding and fairing and sanding and fairing and sanding and fairing and sanding and fairing.... and repeat... finally got the rest of the hardware off too. I am hoping to begin painting by the weekend.

then I made a new spacer for my mast step (the PO used a piece of wood that was deteriorating at this stage, so I used starboard)

then through today I have been sanding and fairing and sanding and fairing and sanding and fairing and sanding and fairing.... and repeat... finally got the rest of the hardware off too. I am hoping to begin painting by the weekend.

oh and I have also been slowly whittling away at the keel. I have it fully shaped and just need to smooth the leading edge and trailing edge and drill/tap the hole for the eye bolt. that will be done while waiting for paint to dry.