I figure I should put everything I’m doing to fix up my 1988 O’Day 192 in one place so here I go.

So here’s the boat when it arrived to me and some shots from before.

When I got the boat I made a list of things that needed to get done and discovered more along the way.

Oxidized Hull

The hull was oxidized all over the place. After some research and checking the boat I figured out it was a failed coating of Poliglow. Took a bit of experimenting to find the best way to remove it but here’s what worked best:

Zep Heavy Duty Floor Stripper

1000 grit wet sand

3M Heavy Duty Rubbing Compound

Presta Polish

Colonite Fleet Wax

Test area, you can already see the difference.

And here’s some of the progress.

After finishing the hull I had a week of hard rain every day. Killed any chance I had to work but also revealed that there were multiple leaks. So I spent the next week finding and repairing everything I could find. Here’s the spots I found leaking:

Back stay chainplate

Stern light

Stern lifeline stanchions

Stern cleats

Bulkhead mounted compass

Bulkhead mount knotmeter

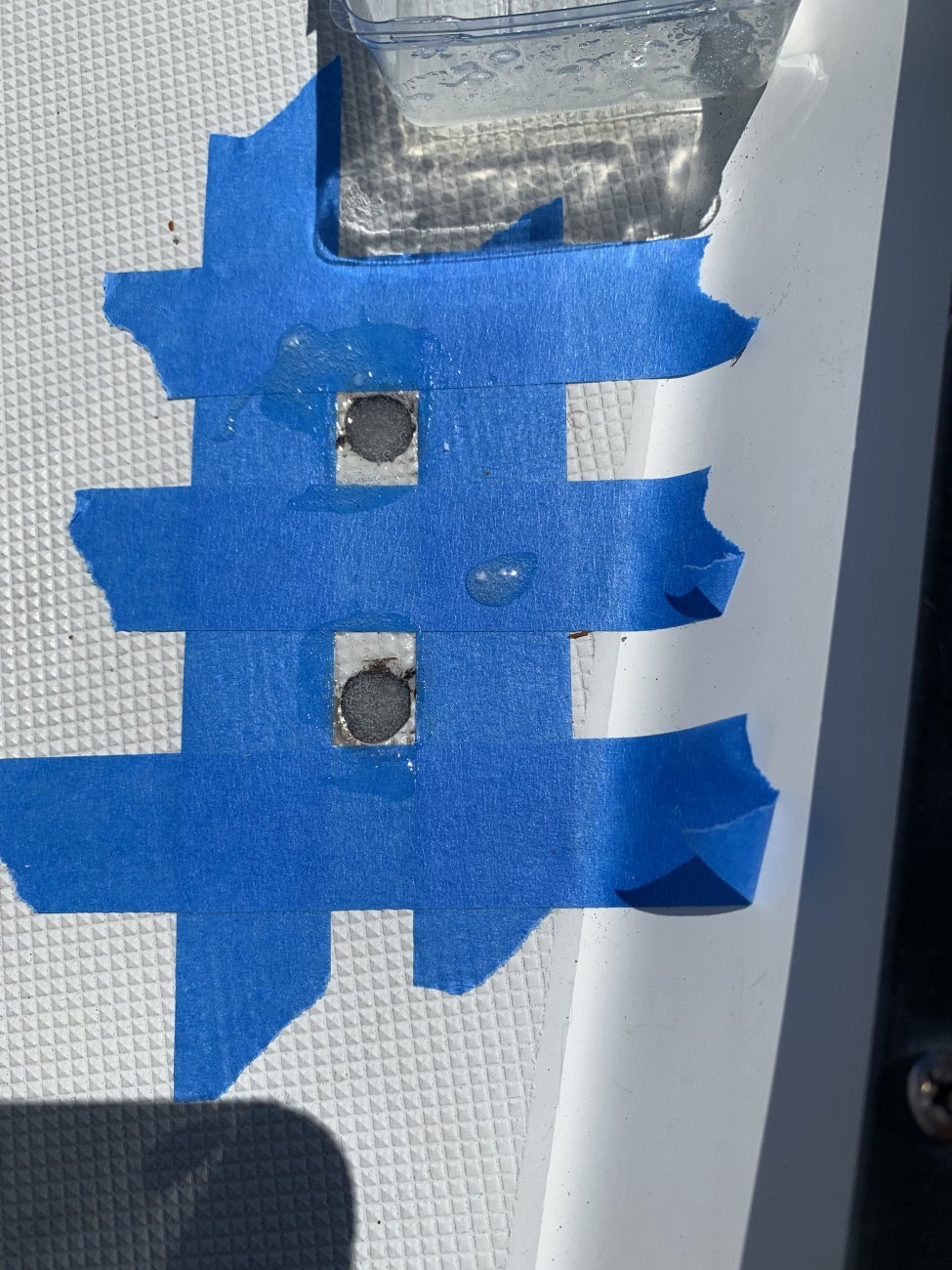

I used Bed It butyl tape to re bed everything. Then I found another leak and this one a bit more serious. The side stay chain plates were leaking. Figured I’d remove them and re bed like everything else. Wrong. The holes drilled through the deck were much larger than the bolt needed and leaked water into the cabin.

So I cleaned them out, chipped away at some of the core that was exposed, and filled them with thickened epoxy. Since I was already mixing epoxy I figured I might as well just do both sides (port and starboard).

The plan is to drill those holes to the proper size then re bed the chainplates with butyl tape.

Here’s a shot from when I finally got to put up the mast to see what was going on. Unfortunately, in the process I bent the home made hinge step that the previous owner made. It’s super heavy duty but has very tight tolerances and I was just off enough that I bent it. Going to take the bent step to a machine shop to get repaired hopefully.

With the rig I found that one of the spreaders was bent. RigRite wanted about $200 for a single spreader so I broke out the heat and got the spreader straight again. Just need to replace the sheaves for the internal boom lines.

Up next:

- Fixing the mast step

- Fixing the ding in the centerboard

- Gelcoat touch up on the hull by the bow

- Installing an inspection port so I can put a new motor mount on.

- Replacing the fuel fittings

- Replacing the cockpit drain hose

- Replace mast head light

- Replace sheaves at outboard end of boom

- Install a vang

- And I’m sure more as I go along

I’ll keep updating as I go. If you have any questions please feel free to ask.

So here’s the boat when it arrived to me and some shots from before.

When I got the boat I made a list of things that needed to get done and discovered more along the way.

Oxidized Hull

The hull was oxidized all over the place. After some research and checking the boat I figured out it was a failed coating of Poliglow. Took a bit of experimenting to find the best way to remove it but here’s what worked best:

Zep Heavy Duty Floor Stripper

1000 grit wet sand

3M Heavy Duty Rubbing Compound

Presta Polish

Colonite Fleet Wax

Test area, you can already see the difference.

And here’s some of the progress.

After finishing the hull I had a week of hard rain every day. Killed any chance I had to work but also revealed that there were multiple leaks. So I spent the next week finding and repairing everything I could find. Here’s the spots I found leaking:

Back stay chainplate

Stern light

Stern lifeline stanchions

Stern cleats

Bulkhead mounted compass

Bulkhead mount knotmeter

I used Bed It butyl tape to re bed everything. Then I found another leak and this one a bit more serious. The side stay chain plates were leaking. Figured I’d remove them and re bed like everything else. Wrong. The holes drilled through the deck were much larger than the bolt needed and leaked water into the cabin.

So I cleaned them out, chipped away at some of the core that was exposed, and filled them with thickened epoxy. Since I was already mixing epoxy I figured I might as well just do both sides (port and starboard).

The plan is to drill those holes to the proper size then re bed the chainplates with butyl tape.

Here’s a shot from when I finally got to put up the mast to see what was going on. Unfortunately, in the process I bent the home made hinge step that the previous owner made. It’s super heavy duty but has very tight tolerances and I was just off enough that I bent it. Going to take the bent step to a machine shop to get repaired hopefully.

With the rig I found that one of the spreaders was bent. RigRite wanted about $200 for a single spreader so I broke out the heat and got the spreader straight again. Just need to replace the sheaves for the internal boom lines.

Up next:

- Fixing the mast step

- Fixing the ding in the centerboard

- Gelcoat touch up on the hull by the bow

- Installing an inspection port so I can put a new motor mount on.

- Replacing the fuel fittings

- Replacing the cockpit drain hose

- Replace mast head light

- Replace sheaves at outboard end of boom

- Install a vang

- And I’m sure more as I go along

I’ll keep updating as I go. If you have any questions please feel free to ask.

Last edited: