More odds & ends:

One area I knew about and had debated for a while on the best way to address was a grid-tie on the starboard side behind the galley. This panel used to be behind the original cooler/frig. A little history first:

Years ago, one of the items noted on the initial survey was a soft spot on the floor around the galley sink. the surveyor said it should be easy to fix, just inject some epoxy and that should take care of it. Heck, I didn't know any better so - ok!

I didn't do anything about it for a few years, but after (I think) I'd owned the boat for about 3 years I had a leak coming from the water heater (close to the same area). I pulled the water heater to fix the leak and found that the floorboards under it had rotted completely away! The reason: Hunter used OSB for the floors! I'm not a fan of OSB in any type of construction, but it's definitely a bad idea in a boat. As soon as it gets wet it dissolves!

I have said before that I have been fairly impressed with the construction of the boat and I mean that. But in several areas they went cost over quality, and the floors are one. Interestingly, the bulkheads are all marine ply and tabbed in!

Back to the original floors - the rotted floor under the water heater encompassed essentially the entire galley area which included the soft spot under the galley sink. I started repairs with the intent of just putting new floors in but the more I got into things the more I found. Turns out the foam used to insulate the outside of the reefer box trapped water and had mold. That was the source of the water that had rotted the floor around the sink. Long story short, when I finished I had totally redesigned the galley! Reefer gone, replaced by side loading refrigerator and separate freezer, lots of other mods. All the OSB floor was replaced with marine ply during the interior remodel,

So, this area of the grid was behind the original reefer box. There were (definitely not cracks) cuts in the transverse bulkheads that had been covered by a glass layup. From the looks of it, it almost had to have been that way from the factory. I didn't like the looks of the glass around the cuts but initially only intended to repair those areas. However, after digging a little deeper, I found foam behind the glass filling the gaps between the bulkheads and hull!

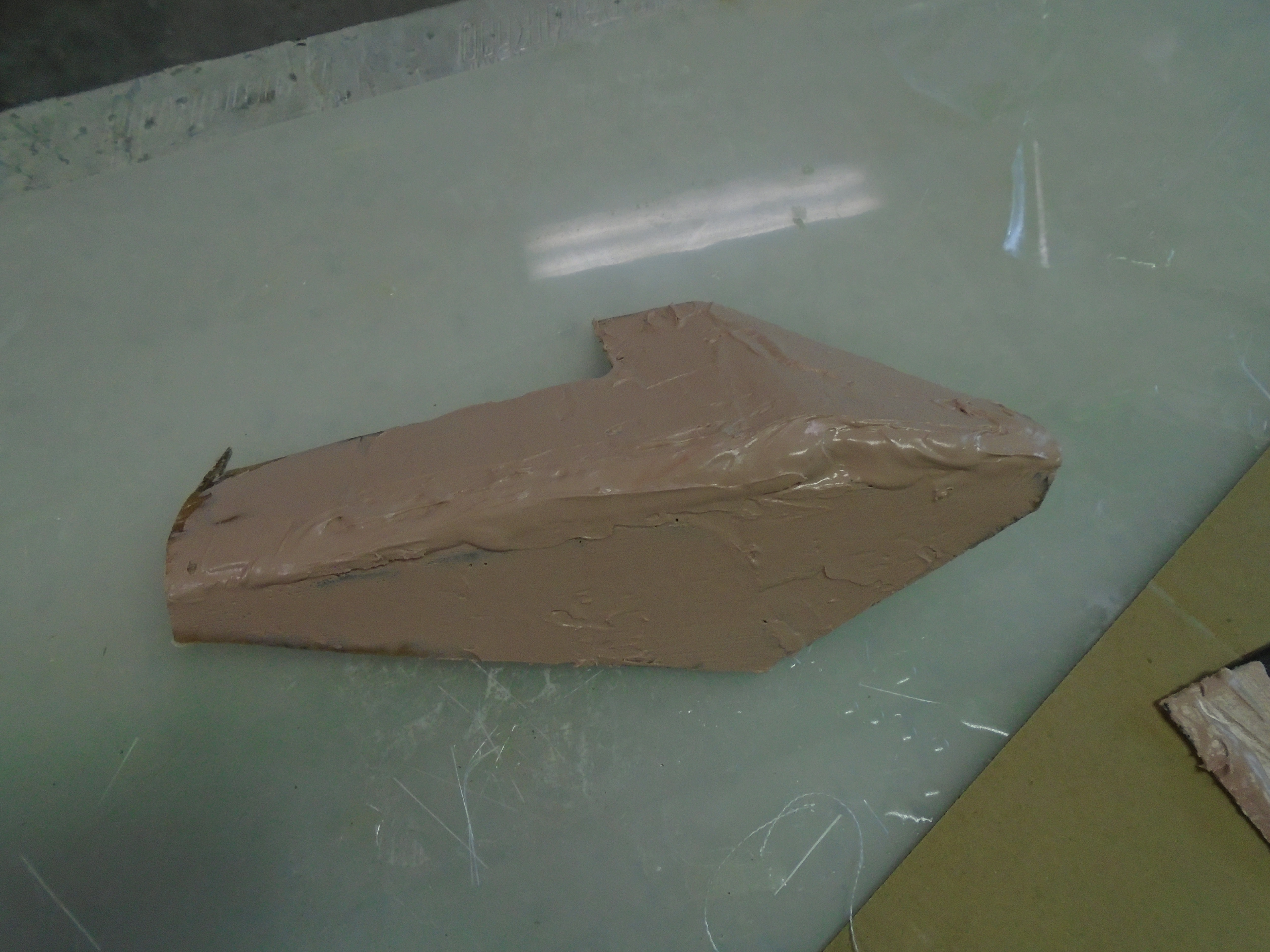

Note: the pics are not before shots, I didn't have my camera with me. These pics are after I had already cut away parts of the panel.

Ummm, No! I also found that the glass had been layed over gelcoat and had delaminated in a few spots so I decided to redo the entire grid-tie panel. Ground properly and prepped:

Today I addressed the cuts in the bulkheads:

Tomorrow I'll lay in the replacement glass to tie the liner to the hull and that's pretty much the last of the big jobs (requiring a grinder anyway, lots of big jobs ahead!) and this catches the narrative up to the present! From now on it's real-time on the progress reports. I've got good temps for most of the next week and just got a shipment of epoxy so I should get lots done. Stay tuned!

Cheers,

Mark