After losing a winch when the bolts busted clean off, I got a pair of Lewmar 40 winches. Are standard stainless bolts from the hardware store really strong enough for this application?

Which winch bolts will work for me new winches?

- Thread starter Project_Mayhem

- Start date

O day 25 and a Lewmar 40? I can't imagine they wouldn't be. The winch can exert something like 3000 lbs of shear force spread across 5 bolts 600 lbs each. 60,000 psi for steel ( at a guess) so the bolt diameter should be over 1/100 of an inch? How old were those bolts? The fiberglass should be giving before the bolts I would imagine.

There are virtually no marks in the fiberglass on the winch that popped off! They're Harken 32's from the 90s. The six original Harken bolts were in good condition when I rebedded it over the winter. The female sex bolt that I pulled out of the fiberglass appeared to have thread failure

The boat the new winches came off of had 1/4-20 stainless screws holding them on. Are you calculations based on 1/4" fasteners?

The boat the new winches came off of had 1/4-20 stainless screws holding them on. Are you calculations based on 1/4" fasteners?

Last edited:

SS 316 bolts, backed up and torqued should be fine. My Lewmar 48s have 316 SS 5/16" and they take much more abuse than your winches.

Make sure the winch is set on a flat surface, the bolts are long enough there is a backing plate of adequate size and strength and the deck is solid. I use double thick fender washers on my winches. Use 316 nyloc nuts. If one of the nuts starts to loosen, the stresses on the winch change potentially overloading the other bolts.

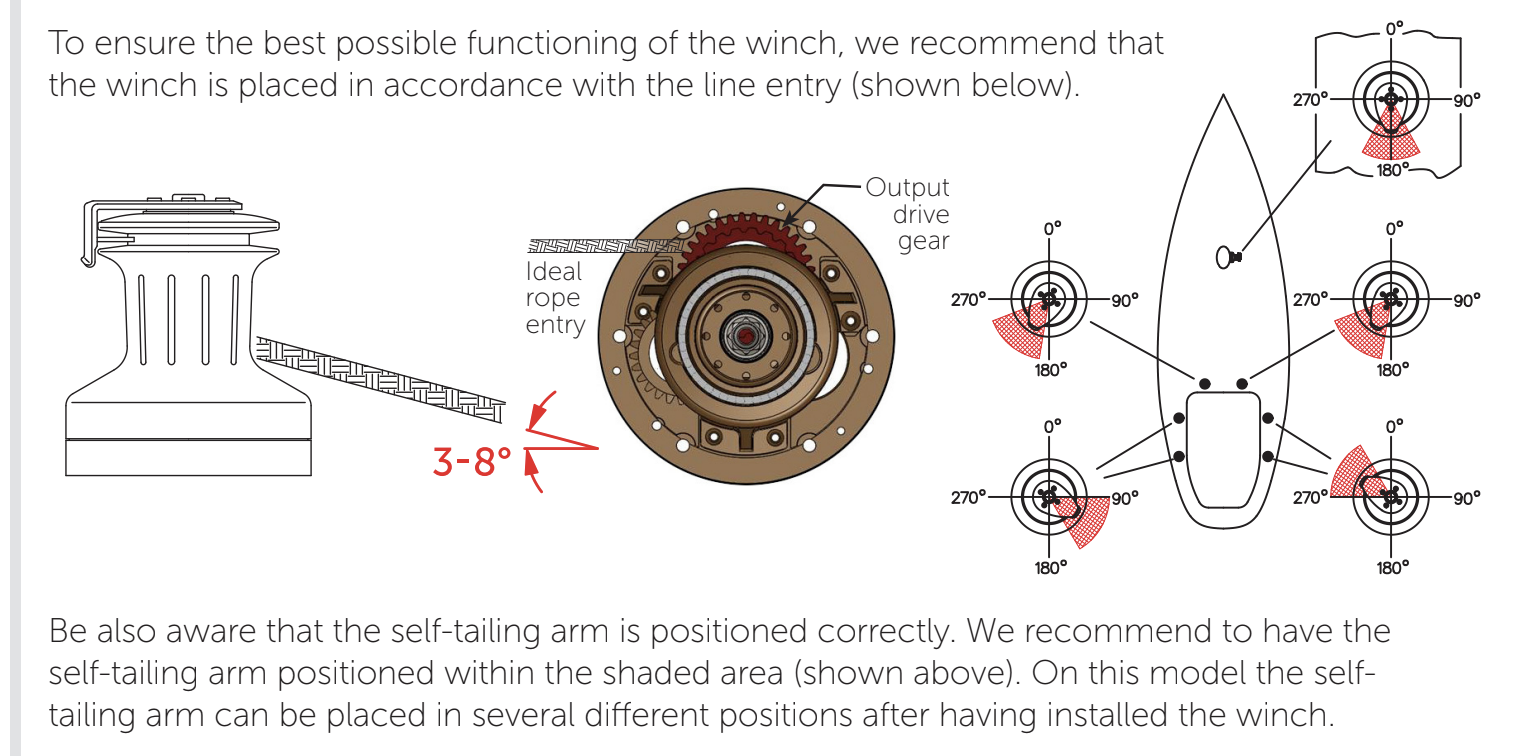

Winches also have to be correctly oriented to the loads. Check the installation manual to get the correct orientation.

Make sure the winch is set on a flat surface, the bolts are long enough there is a backing plate of adequate size and strength and the deck is solid. I use double thick fender washers on my winches. Use 316 nyloc nuts. If one of the nuts starts to loosen, the stresses on the winch change potentially overloading the other bolts.

Winches also have to be correctly oriented to the loads. Check the installation manual to get the correct orientation.

I just installed a pair of Lewmar 45ST's on my boat. 6 bolts. 5/16 flat head 2 inches long. thru the deck, backed by 1/4 plate of aluminum washer and nylock nuts.

If you have the room in your cockpit then it should be no problem.

Install went smoothly with a friend on deck using a large Phillips screwdriver to hold the screw in place while I tightened the nuts from inside the lazarette.

If you have the room in your cockpit then it should be no problem.

Install went smoothly with a friend on deck using a large Phillips screwdriver to hold the screw in place while I tightened the nuts from inside the lazarette.

A 40 power winch amplifies the force on the winch handle by 40X so you can push with 50 lbs say then the load on the sheet is 2000 lbs. Call it 3000lbs. That is supported by the 5? fasteners. How strong is steel? I seem to remember 100kpsi so calling it 60 for some safety margin in any case almost no thickness of steel is needed to support 3000 lbs. ( think of your shrouds for instance)There are virtually no marks in the fiberglass on the winch that popped off! They're Harken 32's from the 90s. The six original Harken bolts were in good condition when I rebedded it over the winter. The female sex bolt that I pulled out of the fiberglass appeared to have thread failure

The boat the new winches came off of had 1/4-20 stainless screws holding them on. Are you calculations based on 1/4" fasteners?

I am not a mech E so this calculation is worth what you paid for it.

I like the Andersen manual on winch orientation. It is clean and simple.

Works for all winches.

Relevant for my EVO Lewmar winches. You can of course use your own judgment/experimentation .

Works for all winches.

Relevant for my EVO Lewmar winches. You can of course use your own judgment/experimentation .

Depends on where you want the tail to fall. That is an individual and boat specific issue. We have horn cleats aft of the winches so the strippers are set up to allow the tail to be cleated.Thanks everyone! Thanks @dlochner for pointing out the orientation. I'll try to fit 5/16" if not, 1/4" will have to do. Any recommendations on stripper position or is that personal preference?

I would not enlarge the holes to use larger bolts.. The base needs enough meat around the bolt hole. Enlarging that will weaken the base, maybe a lot, maybe not, but why risk it?

Are you in fresh or salt water? Typical hardware stores don't carry 316 fasteners to any extent, unless you are lucky.After losing a winch when the bolts busted clean off, I got a pair of Lewmar 40 winches. Are standard stainless bolts from the hardware store really strong enough for this application?

From your description I would look at how your backing plates are setup. You say the female threads stripped. Maybe those were not the same alloy as the bolts?

If you feel you need extra strength you could go to 17-4 PH threaded fasteners but I don't see any pressing need. If you are in salt water 316 stainless should be fine.

dj

The old winches were Harken 32's. The manual showed the bolts that I found them installed with. The bolts snapped when TowBoatUS tried to tie off to the winch with a 4' line that had no stretch so it's totally possible that the load was far higher than what my jib will put on the new ones. The male portion of the bolt is in the bottom of the lake so no chance of post failure inspection. I'm in fresh water so 304 will be fine. It should have a higher carbon content so in theory they should be stronger.Are you in fresh or salt water? Typical hardware stores don't carry 316 fasteners to any extent, unless you are lucky.

From your description I would look at how your backing plates are setup. You say the female threads stripped. Maybe those were not the same alloy as the bolts?

If you feel you need extra strength you could go to 17-4 PH threaded fasteners but I don't see any pressing need. If you are in salt water 316 stainless should be fine.

dj

304 and 316 both have the same carbon contents. They also both have the L version as in 304L and 316L. Those were developed for weldability.The old winches were Harken 32's. The manual showed the bolts that I found them installed with. The bolts snapped when TowBoatUS tried to tie off to the winch with a 4' line that had no stretch so it's totally possible that the load was far higher than what my jib will put on the new ones. The male portion of the bolt is in the bottom of the lake so no chance of post failure inspection. I'm in fresh water so 304 will be fine. It should have a higher carbon content so in theory they should be stronger.

Today, virtually all 304 and 316 alloys are produced to be dual certified - meaning their chemistry conforms to the L and standard requirements. Modern production technology has made it as easy to produce the L version as not.

That being said, often, especially in fasteners, the 304 alloy may have higher mechanical values than the 316 due to the fact 304 responds faster to cold working than 316. As threaded fasteners are often formed through die rolling the 304 threaded fasteners will often have higher mechanical properties than their 316 counter parts. This is not due to carbon content but rather the response to cold working. Now the trade off is that as you increase mechanical properties through cold working, you lower corrosion resistance.

The advantage of 316 over 304 besides it being more resistant to chloride pitting corrosion it is also a tougher alloy than the 304. Toughness is, in simple terms, the ability to withstand forces within the plastic deformation regime... But this is all getting way to heavy for a sailing forum.

In a nutshell both 304 and 316 should work for you especially as you are in fresh water.

dj

Last edited:

Almost all of my SS hardware on my O’day 25 and now on my C30 was bought at an Ace Hardware. A few specialty bits came from McMaster Carr and I chose 316 when offered.After losing a winch when the bolts busted clean off, I got a pair of Lewmar 40 winches. Are standard stainless bolts from the hardware store really strong enough for this application?

Are you sure those 40s will fit? Sound a bit big. Regardless, just use the bolt size the winches are drilled for. No need to reengineer things.

I’d be more concerned that the larger bolt pattern may limit the room for proper sized washers/backing plates.

As far as I know Ace Hardware stuff is pretty good, Home Depot and the others not so much. Biggest problem is most of it is just labeled "Stainless Steel" so you don't know what alloy you're getting. If I need something now I'll go to Ace if there's one around, if I have time I order from BoltDepot.Com. They have most things in 304, 316, silicon bronze, hot dip galvanized and if course regular steel all listed separately so you can specify what you want. Good prices and the quality appears to be excellent.

One of the difficulties especially within the fastener world, is if they aren't saying what stainless, for example 304 or 316, it is possible you are getting 303 stainless. That is a free machining stainless steel often used in fasteners. It does not have the same properties of 304.As far as I know Ace Hardware stuff is pretty good, Home Depot and the others not so much. Biggest problem is most of it is just labeled "Stainless Steel" so you don't know what alloy you're getting. If I need something now I'll go to Ace if there's one around, if I have time I order from BoltDepot.Com. They have most things in 304, 316, silicon bronze, hot dip galvanized and if course regular steel all listed separately so you can specify what you want. Good prices and the quality appears to be excellent.

dj

Oh, what a Pandora's box we have opened.One of the difficulties especially within the fastener world, is if they aren't saying what stainless, for example 304 or 316, it is possible you are getting 303 stainless. That is a free machining stainless steel often used in fasteners. It does not have the same properties of 304.

dj

For the most part I buy fasteners from reputable sources like McMaster-Carr or Bolt Depot and only buy 316 unless the fastener I want is not available in 316.

This does mean, one has to buy more fasteners at a time than one needs. It also means that usually have the fastener I need at sometime in the future. It also means that one fastener rebels and heads to deepest darkest sections of the bilge I have a new recruit at the waiting.

Okay so that was the real problem. In fact count yourself lucky that the bolts snapped. If the bolts were stronger maybe the deck would have given. Boneheaded move on TBUSA's part.The old winches were Harken 32's. The manual showed the bolts that I found them installed with. The bolts snapped when TowBoatUS tried to tie off to the winch with a 4' line that had no stretch so it's totally possible that the load was far higher than what my jib will put on the new ones. The male portion of the bolt is in the bottom of the lake so no chance of post failure inspection. I'm in fresh water so 304 will be fine. It should have a higher carbon content so in theory they should be stronger.

Which begs the question, why was TowBoat US tying a line to your winch? Enquiring minds want to know.The bolts snapped when TowBoatUS tried to tie off to the winch with a 4' line that had no stretch so it's totally possible that the load was far higher than what my jib will put on the new ones.

Pray tell - explain. I truly only wish to provide knowledge...Oh, what a Pandora's box we have opened.

dj