Today it gets real:

- Thread starter pclarksurf

- Start date

Some Thursday night progress in preparation for what will hopefully be an uninterrupted (and not a 100+ degree ) weekend:

Garage cooled off enough to get two layers (one each side of the leading edge ) of 7.5 oz cloth and a cap of biaxial on the ridge. I also had a chance to pull the last remaining small pieces of wood off the deck, I was assuming the blocks were beyond repair-- but as usual nothing is truly beyond repair

Garage cooled off enough to get two layers (one each side of the leading edge ) of 7.5 oz cloth and a cap of biaxial on the ridge. I also had a chance to pull the last remaining small pieces of wood off the deck, I was assuming the blocks were beyond repair-- but as usual nothing is truly beyond repair

I can't recall who to thank for the idea of using PVC as a mast cradle-- but during my wait times between potting all my deck penetrations with Epoxy I took a stab at creating both a mast caddy and a mast step support. Used a 4" PVC sewer pipe for the grand investment of $13.00. Pretty happy with the result and I'll find some appropriate edging material to rim the supports with and I think it will be a winner:

Score! Very hard to find used boat stands out here in the desert: worth the two hour drive to snag 4 for under 40 bucks a pop:

Looks like I have a bit more work to do! Was just going to do some investigatory sanding on my hatch tonight in preparation to repair the slides: good thing I looked -- all 4 corners are open and this poor hatch has been repaired at some point. The light color is delaminated / or at least showing separation from the plywood below. This glass layer may or may not be original.

I'll have to grind the corners back to good wood and see what we can do. Did I mention I love this boat?!

I'll have to grind the corners back to good wood and see what we can do. Did I mention I love this boat?!

Last edited:

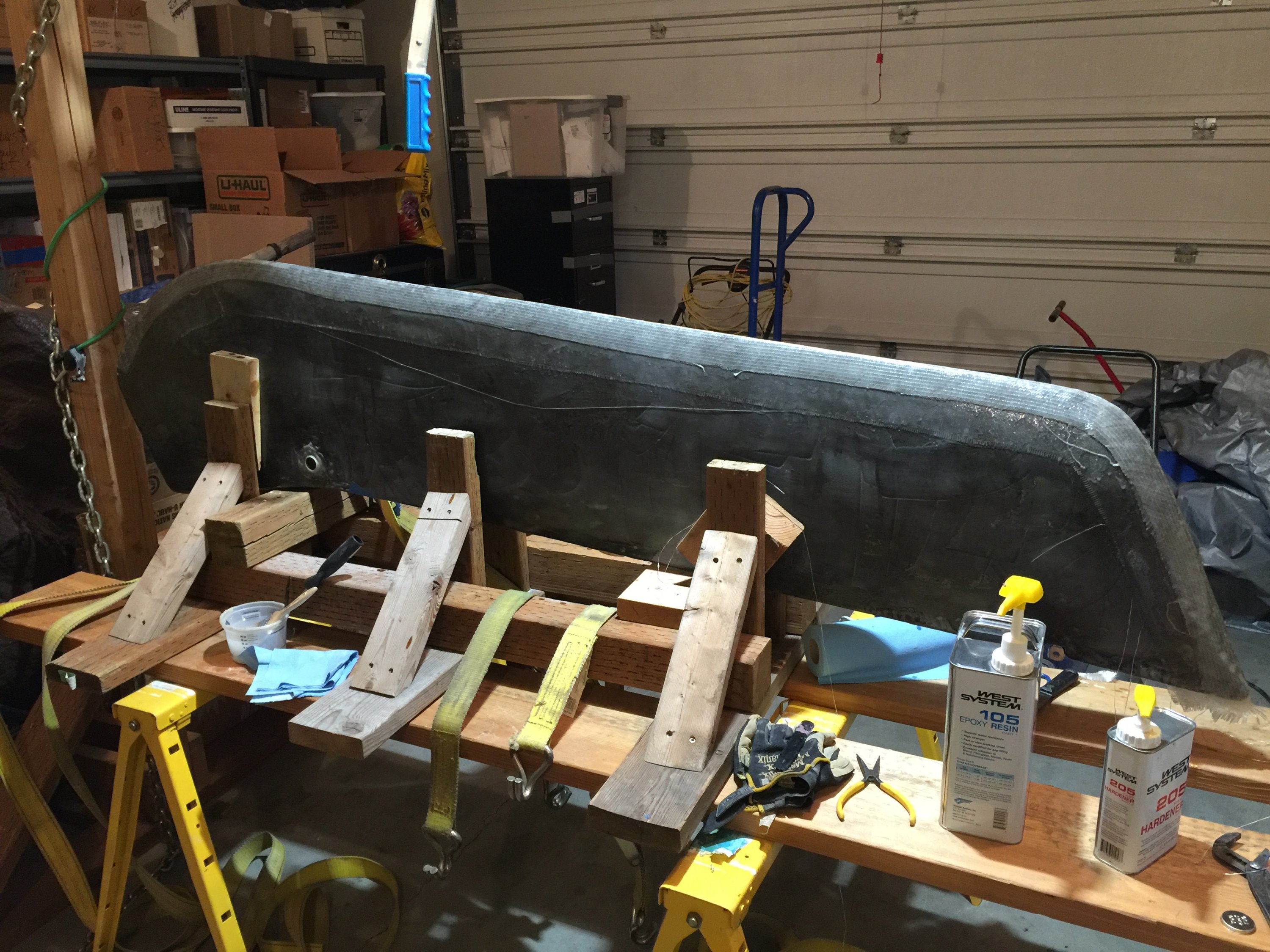

Like everyone else the dog days of summer seem to pile up the work and progress seems fleeting. With vacation complete its back to the keel!

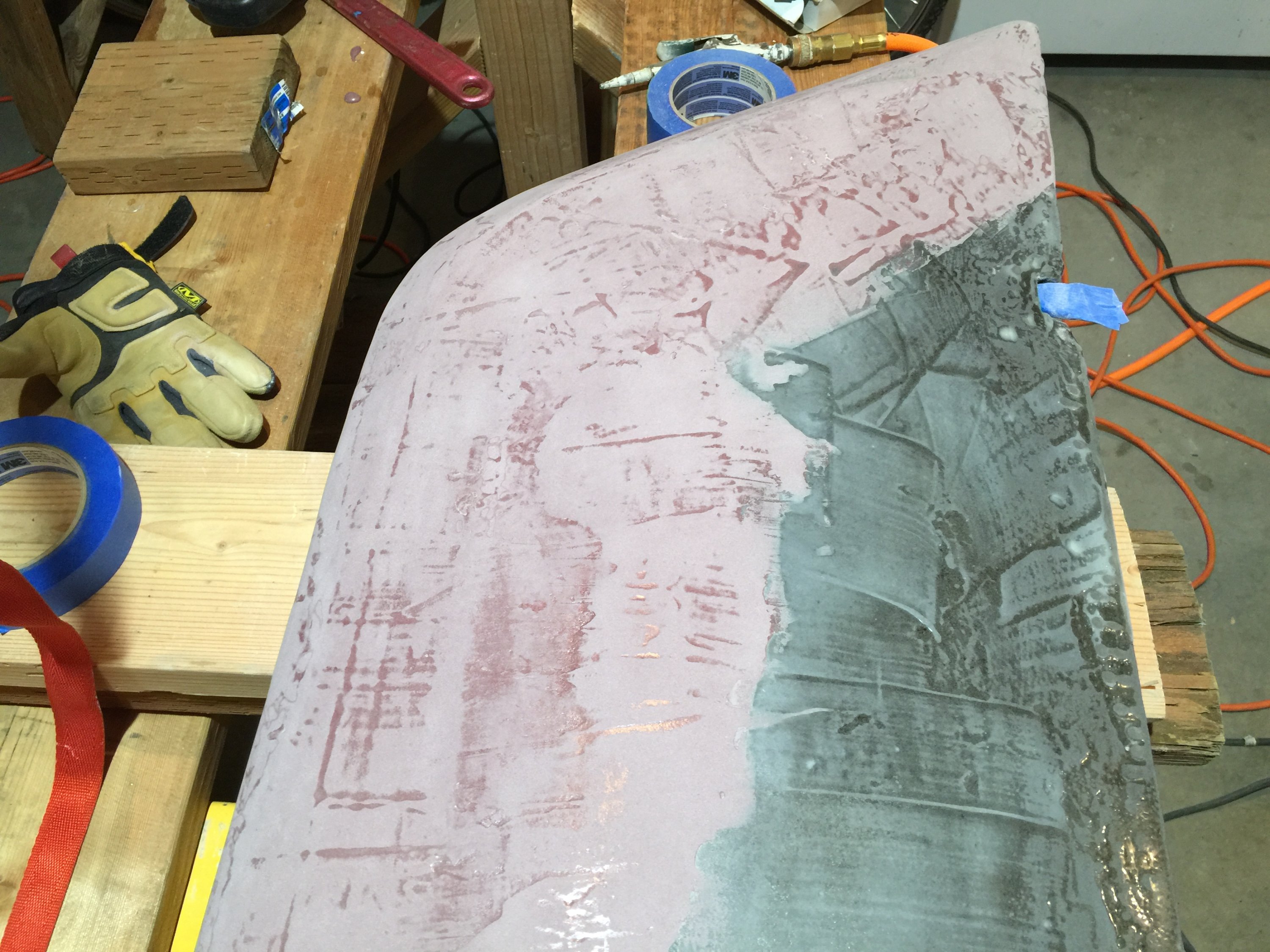

Fairing coats on side 1 covering the leading edge fiberglass tape and the complete skim coat complete before I start building up the foil.

Fairing coats on side 1 covering the leading edge fiberglass tape and the complete skim coat complete before I start building up the foil.

You should be good to go there, no need to build up additional filler for the foil shape. That's a heck of a lot work to gain on a marginal, if not even detectable, gain in performance. I'd long-board sand that fairing filler and paint with Interprotect, bottom paint and done.

It has been so hot here in Oklahoma, work on my C22 has ground to a halt. Looks pretty good on the progress of your keel.

As a follow up to my challenge regarding the Keel Winch clearance -- it's better, but after much review the alignment and placement are good-- the handle will be bent... fair enough. One change I did decide to implement after tossing the idea around alot (probably too much...) was eliminating the mounting bolt penetrations on the cabin step. I had cut mine out previously and replaced with a full 1" piece of Maple-- so had the room to countersink and they are now completely buried in 404 High density filler with a fairing coat to fill level. Some of the install pics below:

2 steps forward , one step back:

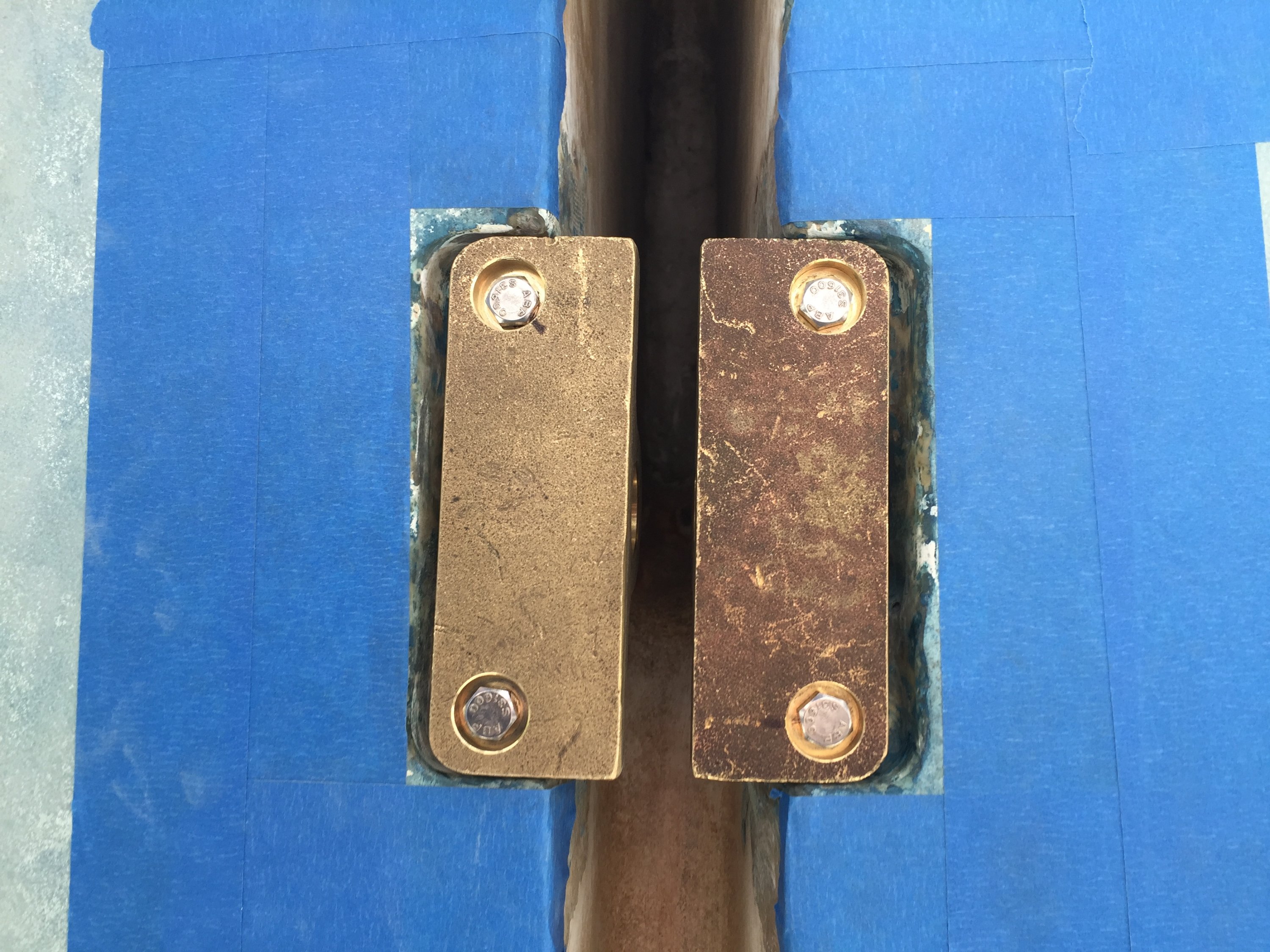

I really really really wanted the keel brakets installed so I could epoxy up the molds and clean up the mounting surfaces and be ready for the keel. But noooo:

My weldments are in decent shape but dang brother they are not square to themselves or anything else for that matter. I manipulated the holes to the point I was able with the basics, but it looks like the brackets are headed to the machine shop this week for a consult.

It doesn't look too bad up close but look at the long view-- not perpendicular to anything never mind the keel.

I really really really wanted the keel brakets installed so I could epoxy up the molds and clean up the mounting surfaces and be ready for the keel. But noooo:

My weldments are in decent shape but dang brother they are not square to themselves or anything else for that matter. I manipulated the holes to the point I was able with the basics, but it looks like the brackets are headed to the machine shop this week for a consult.

It doesn't look too bad up close but look at the long view-- not perpendicular to anything never mind the keel.

Hold the phone... I don't get how this happened? Did you install new weldments? Are those the original brackets or new ones? They are so far off the keel couldn't have fit between them if they were on that way. What gives?

Some of it makes sense: new keel hangers in the old style -- I had the thin but taller than yours version-- so I have more space toward the hull to epoxy /mold.

But with all that said my weldments line up like a trapezoid -- I was trying them out for fit on the bolts, could not get either side threaded without some filing on multiple points.

This would be roughly what I would need to trim if they stayed put-- but I'm not happy with any of it. I'll get them machined to square back up in the pocket and relieve the roughly 1.5 inches for the keel minus a washer each side.

But with all that said my weldments line up like a trapezoid -- I was trying them out for fit on the bolts, could not get either side threaded without some filing on multiple points.

This would be roughly what I would need to trim if they stayed put-- but I'm not happy with any of it. I'll get them machined to square back up in the pocket and relieve the roughly 1.5 inches for the keel minus a washer each side.

As long as the weldments are in their original position you should be fine. CD even says you may have shave down the inside faces just a bit. I have to shave mine down just a hair, but I didn't need to take off very much so I did it on a stationary drum sander... not enough material to justify a mill. It's those outside flanges that don't get close to the end that kind trip me out, plus it makes me wonder how well the round tops on the backside (or inside top) fit into the pocket. My pockets were square and if you look back into my resto thread you'll see how I used epoxy thickened with fairing filler to mold the shape. I just waxed the weldments with zipper wax on the backs and bolted them in. At a minimum I'd use some epoxy filler on the sides to fill that gap, but you might even be able to pull off the whole thing I did and shape the pockets too.

BTW, the washers I used on mine were Delrin (Acetal) that I got from McMaster Carr. They come in a pack of 10 and I only needed one to shim my keel perfectly center. If you PM your address I'll send you a few, I have 6 left after I gave 3 to another buddy who did a keel job.

BTW, the washers I used on mine were Delrin (Acetal) that I got from McMaster Carr. They come in a pack of 10 and I only needed one to shim my keel perfectly center. If you PM your address I'll send you a few, I have 6 left after I gave 3 to another buddy who did a keel job.

and just for grins I installed the old set back on just to confirm-- not as dramatic, but definitely not perpendicular. No idea how old my keel pin was-- I would have thought the damage would have been pronounced. Maybe lucky or the pin got replaced (often). I can only assume if the old hangers are original they fit them to take up the idiosyncrasies of the weldments-- either that or my weldments have been replaced but I didn't see any obvious evidence of that.

Here you can really see the gap in the port hanger-- more aligned front to back, starboard better fit side to side but worse on forward alignment

Here you can really see the gap in the port hanger-- more aligned front to back, starboard better fit side to side but worse on forward alignment

Honestly bro, I'd use the old hangers! Structurally the are just as strong as the new ones... The new ones just are a bit wider. Any gap you may have (which I doubt will be much) can be made up with the Delrin shims. Just keep your new keel pin and send the Hangers Back to CD... If they won't refund you I'm sure they would take them back for credit. In your case I think the old one will actually be stronger, fit better, etc... Those tall square backs will fully seat into the pocket. If you want to clean them up nice, go to a welding supply store and get a metal cleaner that is phosphoric acid based and soak em.. stuff costs $6 a bottle. CLR will work too, just not as strong.

I would at least Test fit your keel with the new pin and the old hangers before you get those new hangers machined...

I would at least Test fit your keel with the new pin and the old hangers before you get those new hangers machined...

Aha moment #1 : I take copious amounts of pictures of things (or at least I try and remind myself to stop and do so...) mostly for my own reference. Thank goodness: as I was contemplating @CloudDiver idea of just giving in to the old I found these in the archives: the original hangers are essentially no better, albeit they don't dramatize the difference as much due to their relative size. I"m off to the machine shop tomorrow at lunch to see what we can come up with-- should be interesting.

Large gaposis on the port side:

and Wonky alignment on the Starboard Hanger:

Large gaposis on the port side:

and Wonky alignment on the Starboard Hanger: