I guess time will tell, but the Rustoleum rusty metal primer is a Alkyd resin paint which has excellent adhesiveness to metals. I'll be the guinea pig on this one and see how it works. I'll keep everyone posted as to how it holds up over the years.No expert here either-- but my gut agrees with you: paint sticks really really well to epoxy, and I can't think of an advantage that paint would have over epoxy for sticking to the extremely porous cast iron. Not to say that there's anything wrong with the opposite approach, but if I'm weighing my options and skillset against the result-- I like Epoxy obviously.

Today it gets real:

- Thread starter pclarksurf

- Start date

In response to my own comment, I went out and inspected my swing keel that I sand blasted last year. I did put a couple of coats of zinc paint on it. The zinc still looks fresh. I may do well to cover the zinc with epoxy, as epoxy should be more durable, but so far it looks good.Daveint-- I guess I'm a creature of habit, haven't had any experience with zinc based paints. Would be interesting to see some results from that process as well. The C22 is a bit of an oddity for me in that I don't usually think of having to deal with Cast Iron in the marine environment. Epoxy is easy for me as I have all the materials on hand already and have a fair amount of experience (read: I've messed up plenty) with it.

Nice-- after taking a breather this weekend, I ran the tap into the eyebolt threads and solved for my not quite parallel eyebolt alignment. Taking CDs advice and will drop some epoxy in and use my syringe to pull it back and re tap again.

I am pleasantly surprised with the epoxy on the bare metal..... It really got in and saturated the entire surface.

I'm also trying my hand at creating a naca 15 foil template-- we'll see how humorous that might turn out

I am pleasantly surprised with the epoxy on the bare metal..... It really got in and saturated the entire surface.

I'm also trying my hand at creating a naca 15 foil template-- we'll see how humorous that might turn out

Last edited:

Hey pclarksuf, looking forward to seeing how the keel turns out. I faired mine last year with a template I got from Stingy Sailor. I'm no racer, so I didn't get it perfect.

The 3cc syringes I got in bulk are outstanding-- a far cry from the 6 dollar a piece versions online. I was thinking 3cc was too little volume but that's a full 1/2 bolt hole full to the rim with one pull. Nifty idea CD!

Attachments

-

674.7 KB Views: 424

-

673.8 KB Views: 421

No expert here either ZG-- stingys template I believe is the naca 0015 foil which in theory I have mapped out below: no time left tonight to cut it out and compare against the real thing but the week is young yet.

Attachments

-

669 KB Views: 420

Retapped the eyebolt threads post epoxy-- and cut out the fairing template and gave it a look against the unfaired keel:

Attachments

-

878.2 KB Views: 403

-

805.2 KB Views: 404

-

612 KB Views: 414

-

586.4 KB Views: 446

Looks awesome... I'm glad you were able to epoxy the eyebolt threads and re-tap them. Just check the fit of the eye bolt and make sure it turns down tight (but not crazy tight) with the eye in the correct direction. I used blue loc-tite on the threads, it dries waterproof.

Its awesome that you made the template for the foil, but something looks off... You might want to recheck your math because its going to take a massive amount of filler to fill that gap. When I did mine I didn't use a foil template, I just smoothed the shape that was there and ended up with what I think is the original foil profile and it was all good. I'd be afraid that much filler could break off if it was banged hard enough... then again epoxy is crazy strong. The fairing filler is the easiest to sand but when cured in epoxy and that thick I'm afraid it would be more brittle. If you are 100% sure your template is correct and you want to add that much to the shape I'd suggest using microfibers to thicken the epoxy for 80% of what you need to build up. Use a long Sure-Form tool (looks like a wood rasp, acts like a jack-plane on epoxy filler) to even the shape longitudinally. Then mix up the the top 20% layer of fairing filler.

Its awesome that you made the template for the foil, but something looks off... You might want to recheck your math because its going to take a massive amount of filler to fill that gap. When I did mine I didn't use a foil template, I just smoothed the shape that was there and ended up with what I think is the original foil profile and it was all good. I'd be afraid that much filler could break off if it was banged hard enough... then again epoxy is crazy strong. The fairing filler is the easiest to sand but when cured in epoxy and that thick I'm afraid it would be more brittle. If you are 100% sure your template is correct and you want to add that much to the shape I'd suggest using microfibers to thicken the epoxy for 80% of what you need to build up. Use a long Sure-Form tool (looks like a wood rasp, acts like a jack-plane on epoxy filler) to even the shape longitudinally. Then mix up the the top 20% layer of fairing filler.

I agree-- the gap to the template is a bit intimidating. I tried raking over Stingy's pics as he faired up and of course it's hard to confirm if he had a similar gap to make up. I will be working up another cut of the template on paper tomorrow-- I originally had the chord length set to 16.5" but the actual is more like 16" -- but either way there's still going to be 1/2" to fill which seemed a bit much. More noodling before I commit any material to that profile.

And I just purchased another gallon of resin and grabbed the larger container of 407 to go with the one I already have. I'll be in need of quite a bit between the keel and the cockpit sole.

Waiting on a new eye bolt before locking it down... mine is ok, but does have some minor deterioration, so might as well replace it while I'm here. I may have to file ever so slightly to level out the mating surface and give me one more thread rotation to gain a solid tight lock.

And I just purchased another gallon of resin and grabbed the larger container of 407 to go with the one I already have. I'll be in need of quite a bit between the keel and the cockpit sole.

Waiting on a new eye bolt before locking it down... mine is ok, but does have some minor deterioration, so might as well replace it while I'm here. I may have to file ever so slightly to level out the mating surface and give me one more thread rotation to gain a solid tight lock.

I used a 16" chord length for my template - it was a pretty good fit with only minor building needed. I'll post the numbers I used to plot the airfoil for comparison when I get back to my computer.I originally had the chord length set to 16.5" but the actual is more like 16" -- but either way there's still going to be 1/2" to fill which seemed a bit much. More noodling before I commit any material to that profile.

Attachments

-

341.1 KB Views: 409

Last edited:

I think you are going way to crazy on this. The fact of the matter is, the thicker profile helps the angle of attack, but also creates drag. Of course you don't want your keel to slip, but the reality is that the angle of attack is very small unless you are in a turn. Even then, the keel is very unlikely to stall, because most of your turns will not be that sharp, as you will loose your forward motion. Fat profiles are good for your rudder, because the angle of attack can be great. But your keel, not so much, especially for a boat that spends most of its time under 6 knots. Making it smooth probably has more impact than a fat profile.

Thanks RJD for posting that pic of your foil template on your keel. PClark, I think the only thing that is off on your template is your perceived centerline. If you were to drop the leading edge of the template from where the centerline is now to where the fist section line intersects the foil line you would eliminate a considerable portion of the gap.

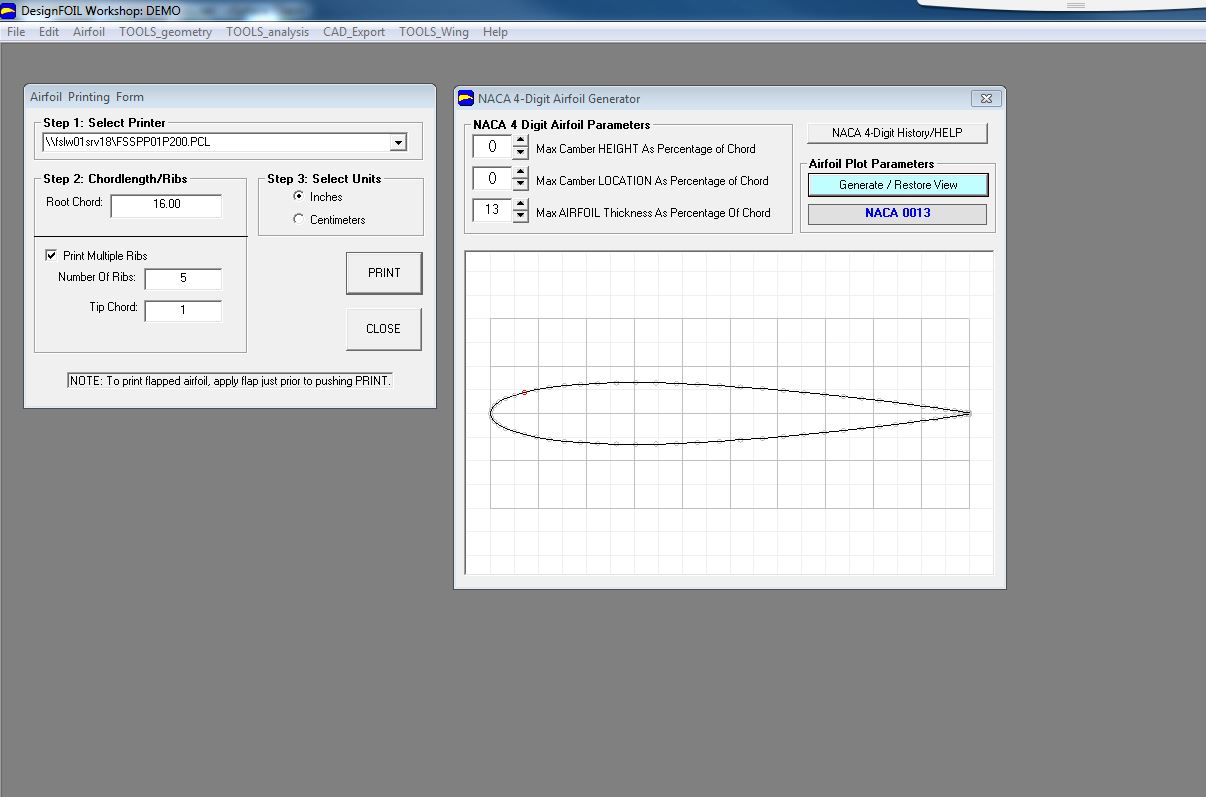

RJD-- fantastic , thanks for the visual-- and CD I agree I've been pulling templates this morning at work and plotting both the 0013 and 0015 NACA foils and I think the "lazy" way out when I build the plywood guide is causing me grief. Someone out there had converted the foil to a 16 point spreadsheet in gradations of 16ths of an inch.... and after digging deeper and getting some better insight-- my first try is headed to the dumpster!

Daveinet-- you are probably correct, in the end it's hair splitting, but since I have the time and the research isn't holding me back from the actual task I figure I'm only doing this once-- might as well get as close as reasonable.

Daveinet-- you are probably correct, in the end it's hair splitting, but since I have the time and the research isn't holding me back from the actual task I figure I'm only doing this once-- might as well get as close as reasonable.

Last edited:

Attached are the numbers I used to plot my NACA 15 template. I put them in an Excel spreadsheet and then converted the spreadsheet to an X-Y graph. Then I stretched the X-Y graph to a chordline of 16 inches and printed it out. Truth be told, I agree with Daveinet - there's no need to go crazy, but I still enjoyed the challenge.

Attachments

-

91.7 KB Views: 333

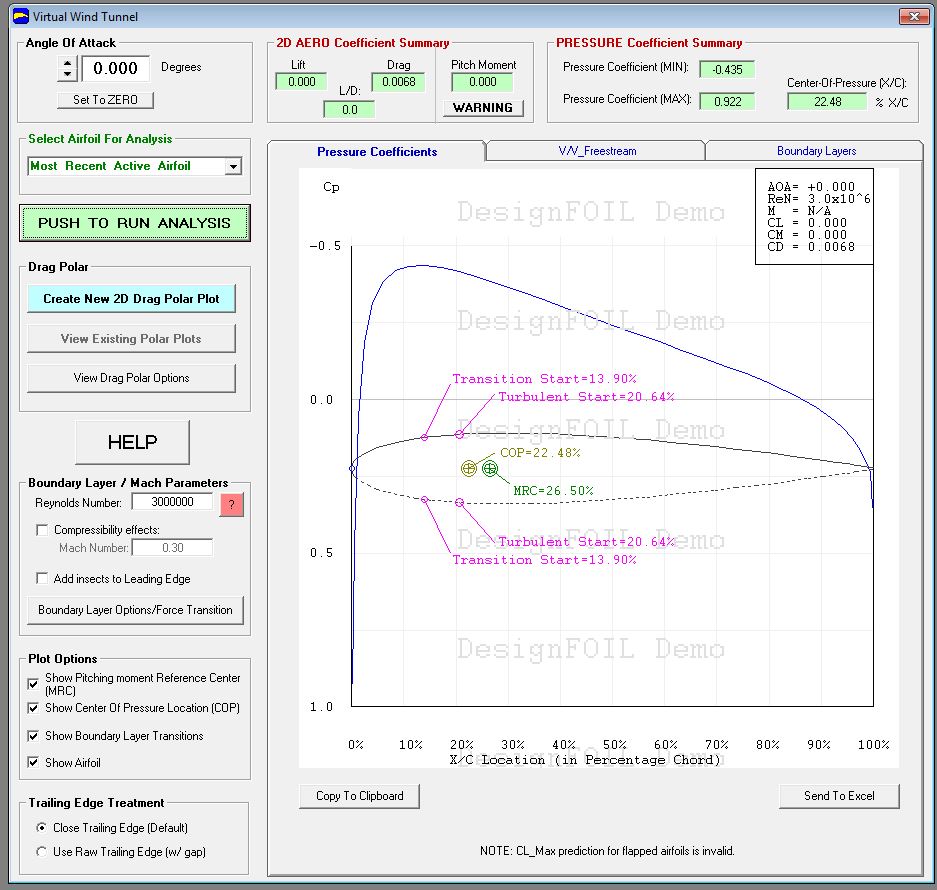

And just because: I stumbled across a demo download of DesignFoil-- which allows you to tweak the foil at will : 71 point distribution and it plots to a laserjet scaled for your chord dimension. functional enough on the trial version to print out multiple looks at naca 15 and 13: Even does virtual wind tunnel calcs. I'll put down the propeller hat and get back to work

Frustrating lack of progress -- thanks PNW weather. But outside issues create opportunity for more coats on the woodwork and an opportunity to get the Keel off to the machine shop. Post Holiday weekend the dust (or at least more of it) can finally fly.

Attachments

-

942.5 KB Views: 363

-

945 KB Views: 365

-

984.7 KB Views: 353

-

1.2 MB Views: 338

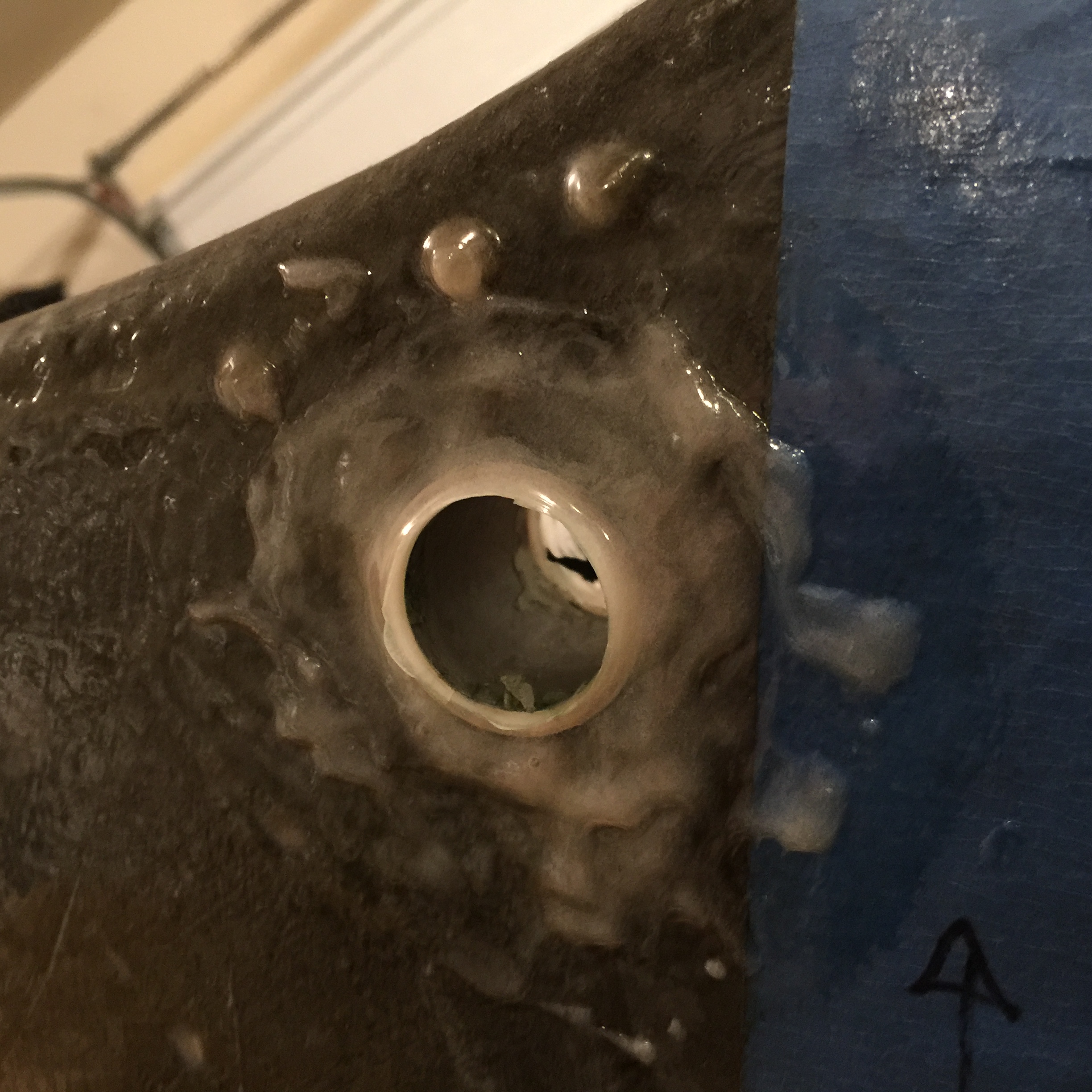

Heart attack moment-- epoxied the keel bushing this evening and used paste wax to coat the pin and the bushing ID-- went out to check on it and it looked as though my version of wax didn't stave off the epoxy. Groaning ensued, but a little love tap with the mallet and all is well!

Spent 100 bucks to have the hole reamed to fit the bushing-- well wort the effort, the fit is exquisite.

Fiberglass for the leading edge tomorrow and hopefully some cockpit sole fairing.

Spent 100 bucks to have the hole reamed to fit the bushing-- well wort the effort, the fit is exquisite.

Fiberglass for the leading edge tomorrow and hopefully some cockpit sole fairing.