So sad that on Tuesday I started to address the soft areas on the foredeck. First discovered this problem when I noticed a cracked more-or-less heel sized damaged spot on the starboard side.

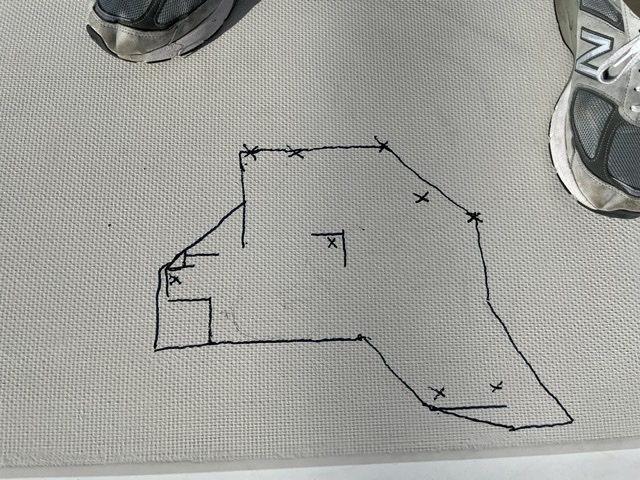

You can see the impression above the bottom left edge of outline.

The outlines include the area identified as soft with hammer taps.

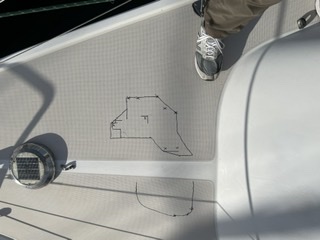

Following the advice of Allan Vaitses (The Fiberglass Boat Repair Manual) I am getting to the core from the interior. I’m cutting with a DeWalt oscillating tool with semicircular blade. I thought this would be safer and cleaner than a mini circular saw, although a small saw would have had depth control, which the oscillating tool does not. Here is the result:

You can see I made a mess of the cuts. A mini circular saw probably would have been been better. Anyway, the tip of the triangular area easily pulled away from the core and broke off from the larger area. The rest of the triangle, which points forward, is firmly attached to the core.

I’m not sure what to do next. The soft area outlined on the deck can’t be fully exposed yet, but the strong attachment of the headliner to the core makes it seem like overkill to rip it all off.

Damaging the interior of my boat this way hurts, but at least some of it needs to be done. I’m just not sure how far to go. Any thoughts will be most welcome.

Peter

You can see the impression above the bottom left edge of outline.

The outlines include the area identified as soft with hammer taps.

Following the advice of Allan Vaitses (The Fiberglass Boat Repair Manual) I am getting to the core from the interior. I’m cutting with a DeWalt oscillating tool with semicircular blade. I thought this would be safer and cleaner than a mini circular saw, although a small saw would have had depth control, which the oscillating tool does not. Here is the result:

You can see I made a mess of the cuts. A mini circular saw probably would have been been better. Anyway, the tip of the triangular area easily pulled away from the core and broke off from the larger area. The rest of the triangle, which points forward, is firmly attached to the core.

I’m not sure what to do next. The soft area outlined on the deck can’t be fully exposed yet, but the strong attachment of the headliner to the core makes it seem like overkill to rip it all off.

Damaging the interior of my boat this way hurts, but at least some of it needs to be done. I’m just not sure how far to go. Any thoughts will be most welcome.

Peter