Another vote for Rod's excellent article with such good pix.

(If you have not clicked on the $ support button on his site, do so. There is nothing quite like it on the 'net.)

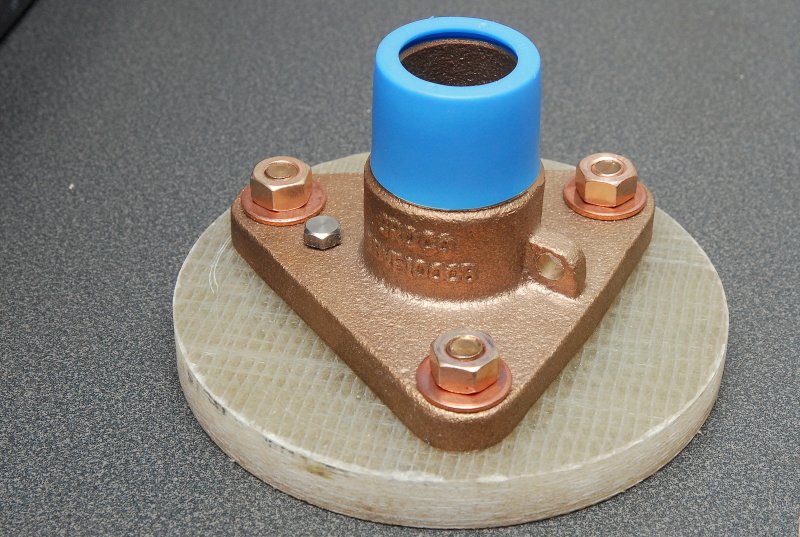

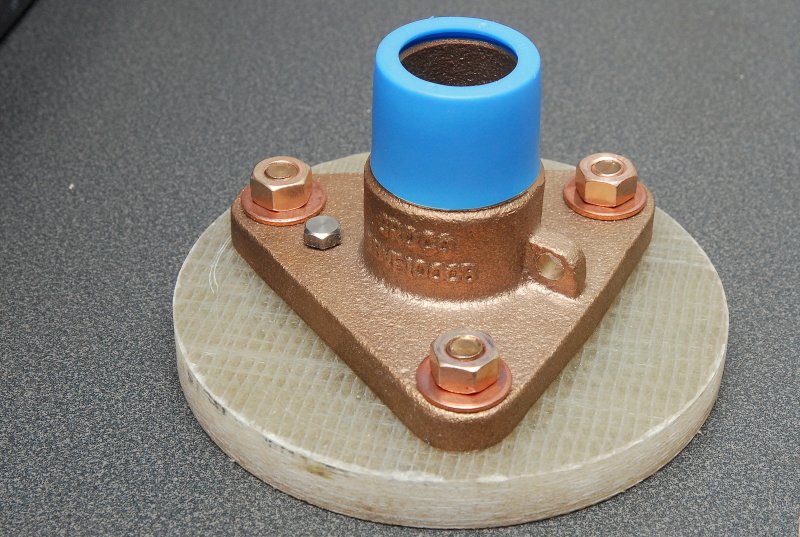

As an alternative, one might consider the way the yard installed all of our new Forespar composite seacocks in the 90's. (The OEM ones were all the weaker "valve on a thru hull" version, by RC Marine, from the 80's.)

Also, proper new backing plates were needed.

The head, recessed or proud, of the thru hull part was of no interest to them. They installed the new valve body thru the backer and screwed the outer part in tight.... with thickened epoxy instead of "sealant". Next the squeeze-out was faired all around, inside. Post cure, the outside "lip" was ground flush. They still work fine decades later and Forespar still produces the same "93" series.

Since the Marelon material is a reinforced plastic, just like our hulls, having it become "one" with hull seemed logical. As for the valve itself, I have had one easily replaced from inside, because the body is screwed to the base.

(The only thing that Forespar has never (IMO) completely addressed in all these years is a hydroscopic tendency of the ball material, and they can bind to some extent.)

Anyhoo.... There seems to be more than one 'right' way to do this.