Most people know that while we race BlueJ hard, we also cruise a lot. And even when cruising, we want top performance from our sails. That's why in the past we've always sailed with our tri-radial laminates up, and take the extra wear and tear while cruising and fun sailing as the cost of doing business. Laminates are great, but you have to take care of them. So I'm always looking.

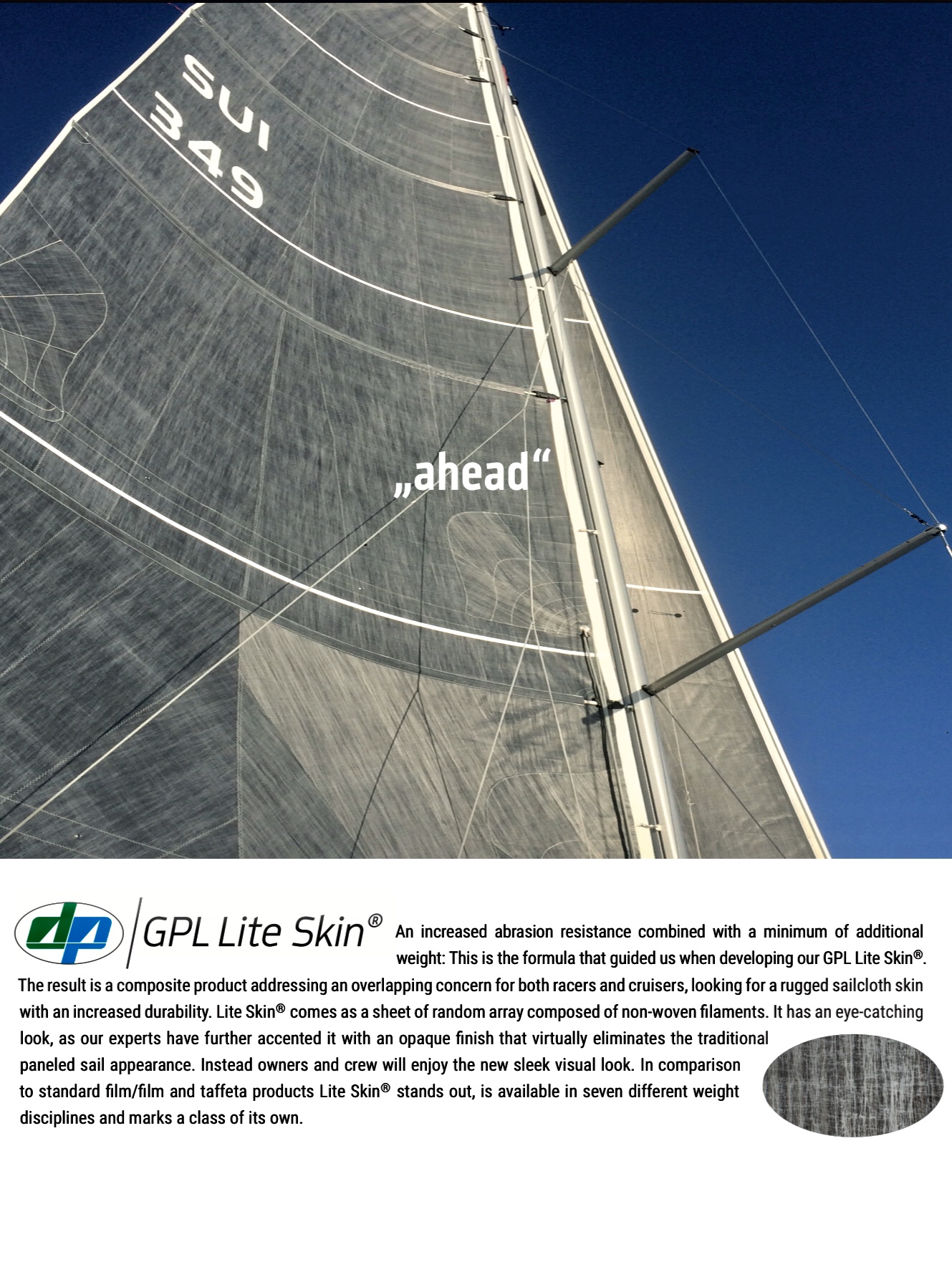

Several years ago I was told about a new cloth from D-P called GPL LiteSkin. While it has a matrix of high-tech strings (in this case technora and carbon), it is not a true laminate. Instead the matrix is somehow laminated and then imbedded in a random array of filament fibers (the so-called LiteSkin). It ends up being a fairly monolithic structure. I have a sample of the material and it's interesting. You can feel the matrix inside, but true to its monolithic nature, you can't pull it apart. And it is for sure more 'cloth-like' then laminates, which feel like plastic. And it does not absorb moisture and dries quick. So that's nicer. The cloth is totally opaque, and is black/gray/silver depending on the light that hits it.

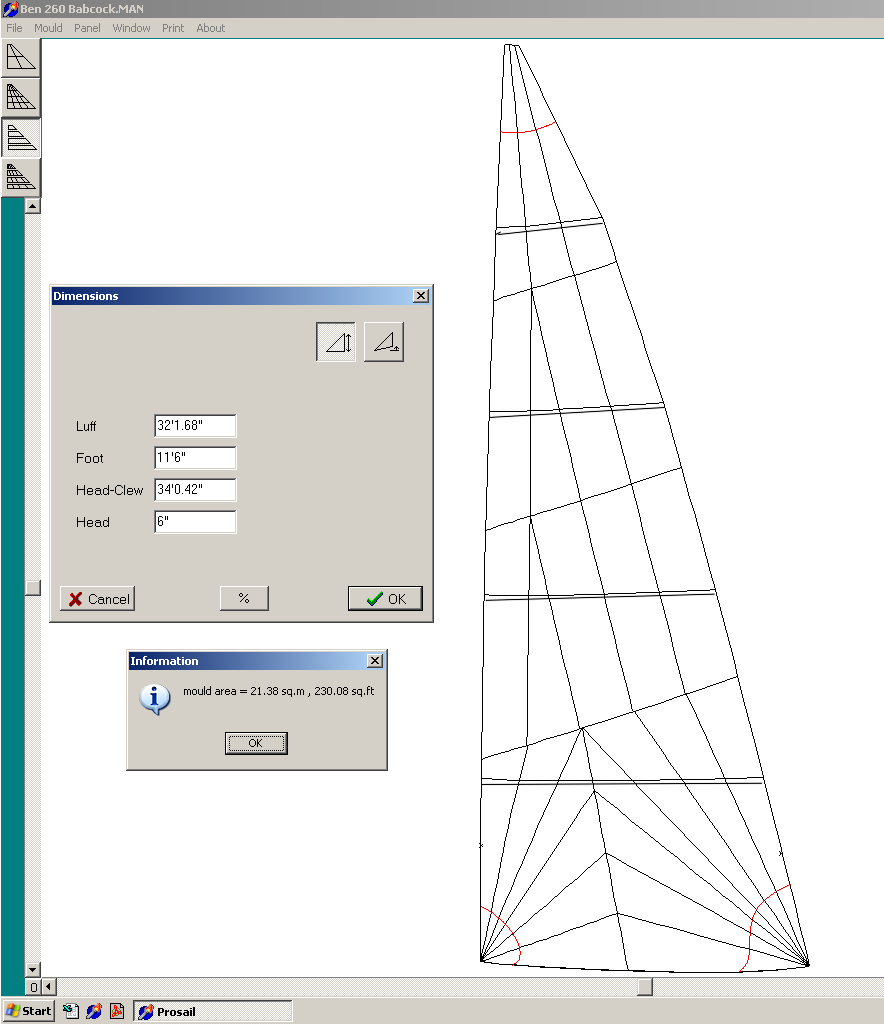

Sounds good, but my at-the-time sails were rather new, and I'd figure I've give the cloth some time to prove itself. Well 4 years later and all the reviews are glowing. The material holds shape, is very wear resistant, and even better does not crease like laminates do. And my jib (4 yo) and main (3 yo) are still in good shape, they are starting to show signs. So it's time. I talked to my sailmaker (we've made up) and ordered a set for next year. At a great price! Here is the main in profile.

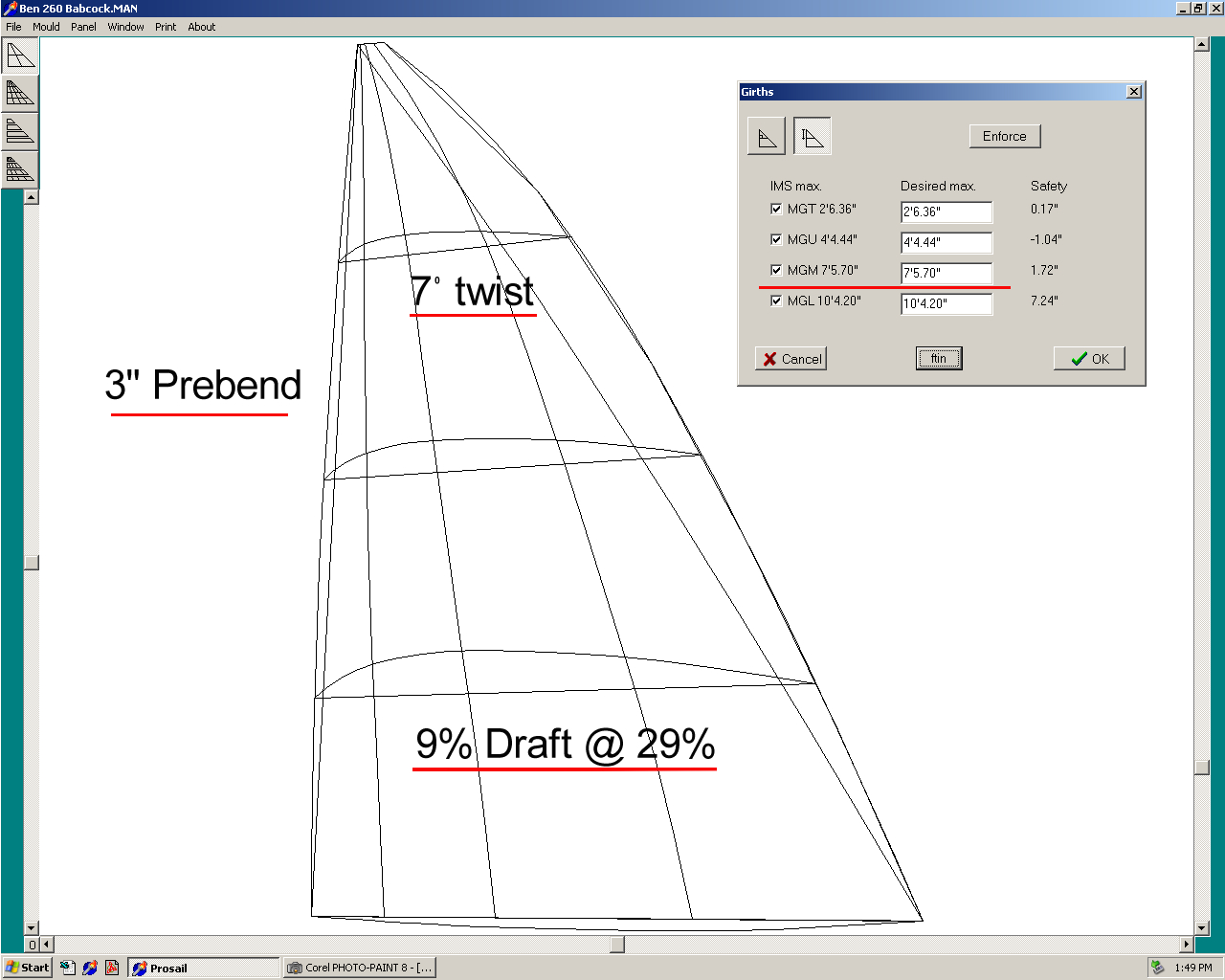

Ended up with tri-radials of almost the exact same size and shape as our last set. We really like them. One interesting point about the cloth, it is so strong in all three directions (warp, fill, bias) that you can make descent sails by broad seaming. But tri-raidal gives better control over the desired shape.

BlueJ is on the hard, but knowing Martin the sails will be here before December. Then all I'll be able to do is touch them!

Several years ago I was told about a new cloth from D-P called GPL LiteSkin. While it has a matrix of high-tech strings (in this case technora and carbon), it is not a true laminate. Instead the matrix is somehow laminated and then imbedded in a random array of filament fibers (the so-called LiteSkin). It ends up being a fairly monolithic structure. I have a sample of the material and it's interesting. You can feel the matrix inside, but true to its monolithic nature, you can't pull it apart. And it is for sure more 'cloth-like' then laminates, which feel like plastic. And it does not absorb moisture and dries quick. So that's nicer. The cloth is totally opaque, and is black/gray/silver depending on the light that hits it.

Sounds good, but my at-the-time sails were rather new, and I'd figure I've give the cloth some time to prove itself. Well 4 years later and all the reviews are glowing. The material holds shape, is very wear resistant, and even better does not crease like laminates do. And my jib (4 yo) and main (3 yo) are still in good shape, they are starting to show signs. So it's time. I talked to my sailmaker (we've made up) and ordered a set for next year. At a great price! Here is the main in profile.

Ended up with tri-radials of almost the exact same size and shape as our last set. We really like them. One interesting point about the cloth, it is so strong in all three directions (warp, fill, bias) that you can make descent sails by broad seaming. But tri-raidal gives better control over the desired shape.

BlueJ is on the hard, but knowing Martin the sails will be here before December. Then all I'll be able to do is touch them!

Last edited: