Hi ggrizzard,

I refinished all the teak veneer plywood panels in the boat. They were first finished with oil and previous owner put a layer of varnish, so the varnish did'nt stay on.

I used different kind of tools and products:

1- Remover with woodworking scrapers to do not damage the thin layer of veneer. Here is a picture of what kind of scrapers I used:

2- Same kind of scrapers have been used for the tricky parts and angles. I got convexe and concave curved scrapers for the round surfaces.

3- Then, I used 220 and 320 sandpaper with orbit sander machine. A little bit od hand sanding was done for parts who cannot be done by my sander.

3- I used my Shop Vac to clean the dust.

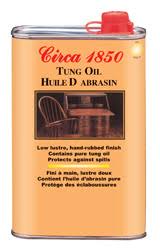

5- I finally washed with acetone all the surfaces and applyed 3 or 4 layers of tung oil depending of the wood absorption.

I refinished all the teak veneer plywood panels in the boat. They were first finished with oil and previous owner put a layer of varnish, so the varnish did'nt stay on.

I used different kind of tools and products:

1- Remover with woodworking scrapers to do not damage the thin layer of veneer. Here is a picture of what kind of scrapers I used:

2- Same kind of scrapers have been used for the tricky parts and angles. I got convexe and concave curved scrapers for the round surfaces.

3- Then, I used 220 and 320 sandpaper with orbit sander machine. A little bit od hand sanding was done for parts who cannot be done by my sander.

3- I used my Shop Vac to clean the dust.

5- I finally washed with acetone all the surfaces and applyed 3 or 4 layers of tung oil depending of the wood absorption.

Last edited: