Hurth HBW50 replacement

- Thread starter uralite

- Start date

-

- Tags

- hurth prm60 transmission

Thanks guys for encouragement. I really appreciate it. I had not realized that it has been 5 weeks. Man, it takes what it takes, but my bravery took a while to build. I will admit I'm somewhat worried that once engine is going, I might find something else. Murphy always shows up on my watch. Ill put that thought back into the deep recesses of my brain for now.

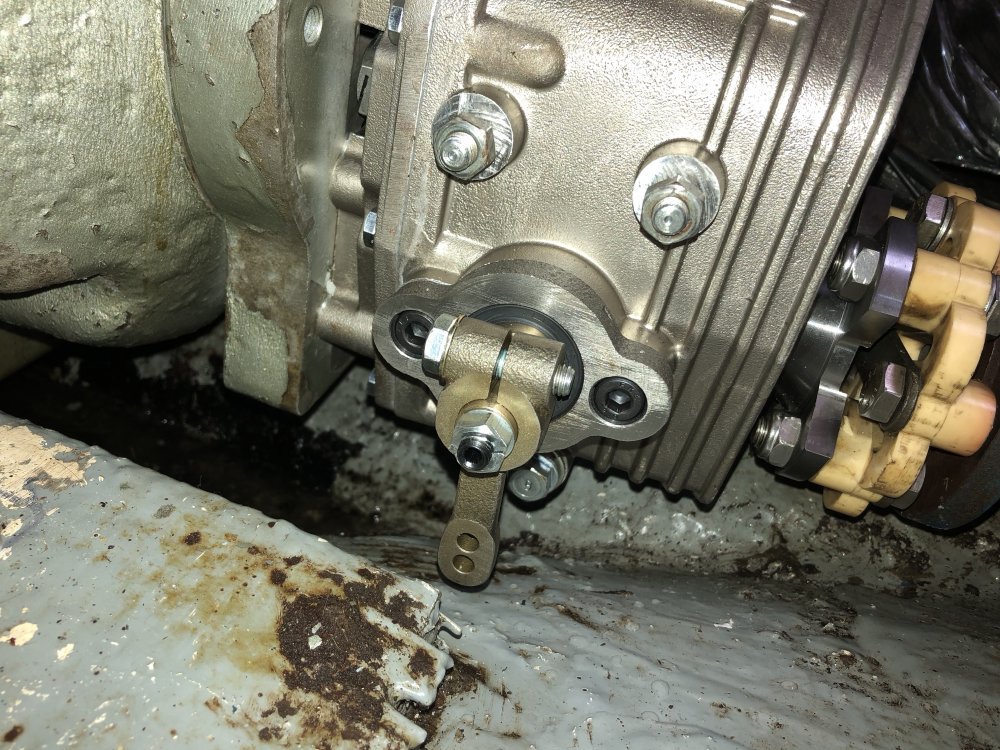

Yesterday I took the drawing for shift lever bracket over to a fab shop and they recommended aluminum for shift lever bracket in 1/4" thickness. The holes on transmission appear to be 8 mm studs with 8 mm nut, the nut off Hurth studs are exactly the same, imagine that. Originally I was told 1/4" taller gearbox, then 3/8". Not really sure in life if 1/8 matters, but the motor mounts were at the ends of their stops for adjustment, so I went 1/8 taller shim so there is more adjustment available. I went with 3/8" stainless shims based off motor mounts being steel and not wanting to have dissimilar metals. Not sure if that argument really holds for stainless and coating on mounts, but that was what I decided to do. Now off to Ace to try and find huge hardened lags for motor mounts. When I backed the lags on the most corroded mount, they felt solid and required effort to turn with socket. Praise God, maybe Murphy had the day off. I did not want to find mushy rotten bed logs. Im going to go with 3/8" longer, is there anything I should put in there with lags? What about under mounts/shims? I know they need to be removable, but seems like some type of sticky goop should be in there? Epoxy, Gorilla glue or 3m 5200? Hahaha, just kidding. Im open to any suggestions.

Yesterday I took the drawing for shift lever bracket over to a fab shop and they recommended aluminum for shift lever bracket in 1/4" thickness. The holes on transmission appear to be 8 mm studs with 8 mm nut, the nut off Hurth studs are exactly the same, imagine that. Originally I was told 1/4" taller gearbox, then 3/8". Not really sure in life if 1/8 matters, but the motor mounts were at the ends of their stops for adjustment, so I went 1/8 taller shim so there is more adjustment available. I went with 3/8" stainless shims based off motor mounts being steel and not wanting to have dissimilar metals. Not sure if that argument really holds for stainless and coating on mounts, but that was what I decided to do. Now off to Ace to try and find huge hardened lags for motor mounts. When I backed the lags on the most corroded mount, they felt solid and required effort to turn with socket. Praise God, maybe Murphy had the day off. I did not want to find mushy rotten bed logs. Im going to go with 3/8" longer, is there anything I should put in there with lags? What about under mounts/shims? I know they need to be removable, but seems like some type of sticky goop should be in there? Epoxy, Gorilla glue or 3m 5200? Hahaha, just kidding. Im open to any suggestions.

Last edited:

Edit: I'm calm now, shoulda got aluminum shims, didn't realize mounts were aluminum.

Secondly, I ordered Damper plate and it is just as wrong as the first wrong one!!

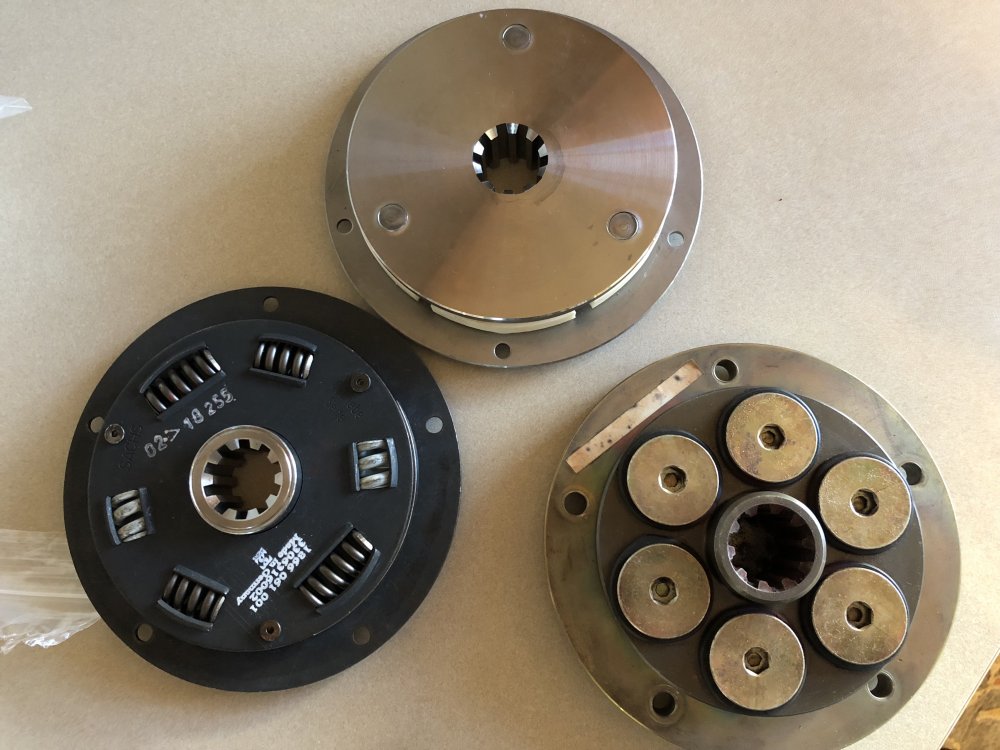

The top 2, (black and silver) are the standard ones for hurth/PRM gearbox for the Universal engine. Standard Catalina. Of course mine is neither standard or the same. The holes are 6 mm and drilled in a different location!! Bleep BLEEP, BLEEP!! Sorry for the confusion, this may be why I am having such a hard time getting the right part, I'm not speaking correct language to parts guys on phone.

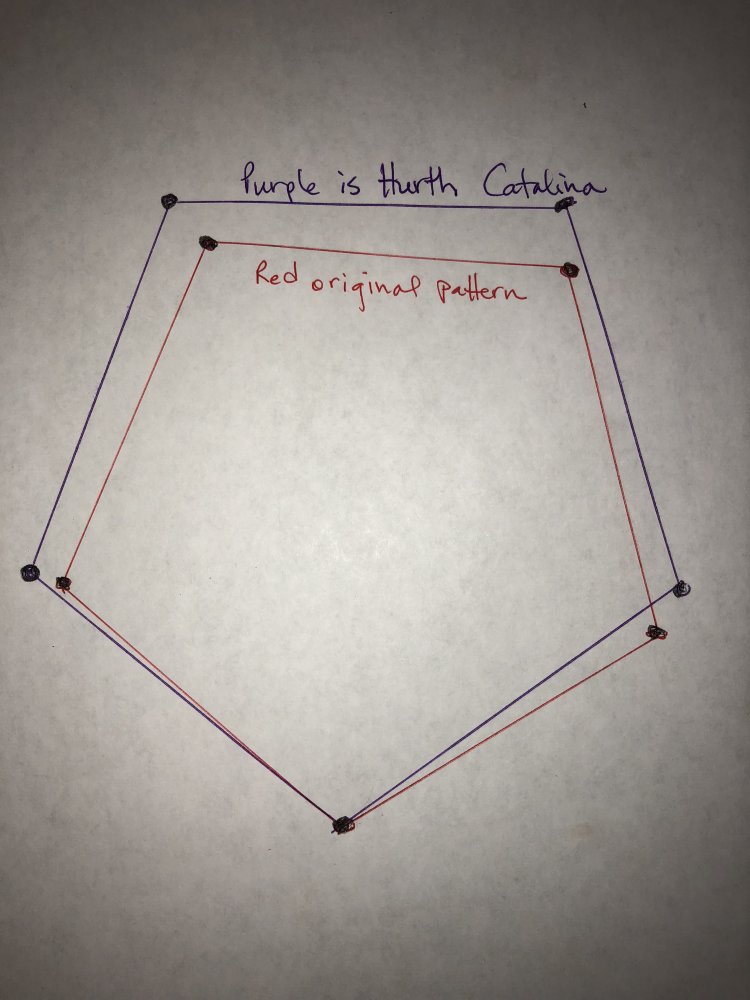

The splines are the same. When the bottom hole is aligned, the rest are not. Red lines are the original, purple is the Catalina from Hurth. I originally did want to drill holes bigger, but then when I looked at alignment, it would be uber hard to get everything centered right? So I will try and call tomorrow to both people and discuss how I can better communicate issue with my non-mechanical speech, check in with the yard mechanics to see if they have a suggestion, I did try and PM Mainesail, which he is likely extremely busy this time of year and I was afraid perhaps I was too impulsive. Be calm, think it through and be ready to feel like an ass on the phone. All good here!!

Secondly, I ordered Damper plate and it is just as wrong as the first wrong one!!

The top 2, (black and silver) are the standard ones for hurth/PRM gearbox for the Universal engine. Standard Catalina. Of course mine is neither standard or the same. The holes are 6 mm and drilled in a different location!! Bleep BLEEP, BLEEP!! Sorry for the confusion, this may be why I am having such a hard time getting the right part, I'm not speaking correct language to parts guys on phone.

The splines are the same. When the bottom hole is aligned, the rest are not. Red lines are the original, purple is the Catalina from Hurth. I originally did want to drill holes bigger, but then when I looked at alignment, it would be uber hard to get everything centered right? So I will try and call tomorrow to both people and discuss how I can better communicate issue with my non-mechanical speech, check in with the yard mechanics to see if they have a suggestion, I did try and PM Mainesail, which he is likely extremely busy this time of year and I was afraid perhaps I was too impulsive. Be calm, think it through and be ready to feel like an ass on the phone. All good here!!

Last edited:

I'm sorry for your frustration. I confess I'm having trouble understanding the issue. All seem to have 5 holes for bolts to the firewall. Are the bolt circle diameters different? Are the holes not spaced equally around the bolt circle, as in 72º apart? Your original (lower right?) appears to have larger diameter holes; couldn't the new damper's holes be opened up to fit? (I assume the spline is the same size on all.)OMG, I got the motor mounts and the damper plate from PYI and I think I may just absolutely lose my mind. First: Motor mounts, when I looked online at PYI it said mounts were steel so I bought the more expensive Stainless steel shims to go under to avoid dissimilar metals.

View attachment 152908

They are really nice, but much too light to be steel. They are ALUMINUM!!! Thats gonna cost me time and money to have aluminum ones made.

Secondly, I ordered Damper plate and it is just as wrong as the first wrong one!!

View attachment 152909

The top 2, (black and silver) are the standard ones for hurth/PRM gearbox for the Universal engine. Standard Catalina. Of course mine is neither standard or the same. The holes are 6 mm and much bigger drilled in different location!! Bleep BLEEP, BLEEP!! I am trying not to be so frustrated, but why can we not use standard? Why?

Thats $400 of wrong parts. I can send back both, but seriously, im not sure how to solve this or who to talk to. Im gonna PM Mainesail. So much for install this weekend.

Ill be back in 1 hour ready to drive on and fix this. But right now I'm melting down in frustration.

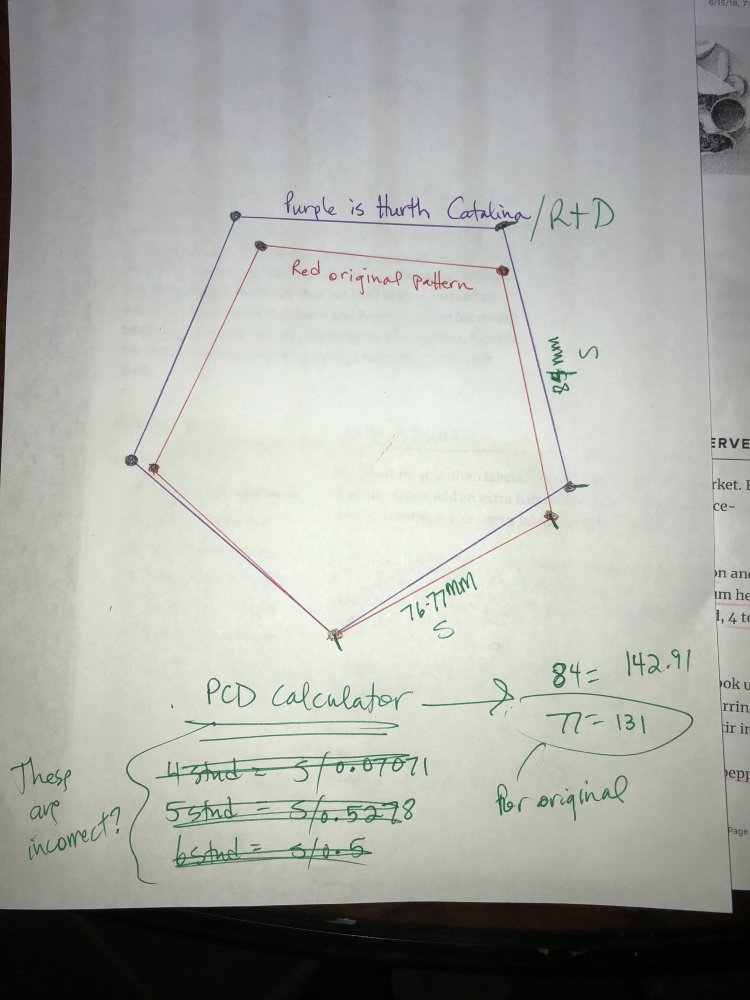

Ok, so I called PYI back and did the measures again. I was missing what the "bolt pitch circle" measure is. I googled this and redid my calculations. There were a few frustrating things about my attempt at measuring that the smart engineering/marine mechanical people will likely point out was my poor communication, which is true. Personal thanks also to Mainesail who replied to PM and gave me good advice and plan.

I was melting down a little last night until I just realized I would seek wise counsel, then make a decision with worst case using old damper that does not look too bad in spite of it not being the "right thing to do." That let me mentally move on.

On the page above I used a bolt pitch calulation from online, that is the scratched out figures above, that were incorrect based on comparison to known from R&D. That did not help and I did not realize until after I used a different online calculator and the figures matched bolt pitch pattern from R&D. I used a tape measure and it was not the most precise, but ball park. The Catalina/Hurth and R&D Damper plate use a 142 mm bolt pitch circle and my original is around 131 mm. After discussing with PYI rep, they independently referred me back to the man who knows all on west coast about marine transmissions, Mike Vogt at Harbor Marine. HAHAHA, just go to the source right!?

I called Mike back and we got down to it. Mainesail and Mike both agreed that original manufacturer is best option for engine specific stuff. Original manufacturer says marinizer/install company did bell housing and damper and they don't know what it is plus I don't have serial number.

Options are to pull flywheel and have machine shop drill and tap for standard damper or use old one........

Frankly, I am done and want to go sailing. I am not cool with pulling flywheel and re-drill and tap at machine shop. The original after I cleaned it up looks good enough and is extraordinarily beefy. I know, I know, ...But is it almost July and I'm done dickin' around.

Will update as things go along. Ill still clean it some more above and grease it well with install.

I was melting down a little last night until I just realized I would seek wise counsel, then make a decision with worst case using old damper that does not look too bad in spite of it not being the "right thing to do." That let me mentally move on.

On the page above I used a bolt pitch calulation from online, that is the scratched out figures above, that were incorrect based on comparison to known from R&D. That did not help and I did not realize until after I used a different online calculator and the figures matched bolt pitch pattern from R&D. I used a tape measure and it was not the most precise, but ball park. The Catalina/Hurth and R&D Damper plate use a 142 mm bolt pitch circle and my original is around 131 mm. After discussing with PYI rep, they independently referred me back to the man who knows all on west coast about marine transmissions, Mike Vogt at Harbor Marine. HAHAHA, just go to the source right!?

I called Mike back and we got down to it. Mainesail and Mike both agreed that original manufacturer is best option for engine specific stuff. Original manufacturer says marinizer/install company did bell housing and damper and they don't know what it is plus I don't have serial number.

Options are to pull flywheel and have machine shop drill and tap for standard damper or use old one........

Frankly, I am done and want to go sailing. I am not cool with pulling flywheel and re-drill and tap at machine shop. The original after I cleaned it up looks good enough and is extraordinarily beefy. I know, I know, ...But is it almost July and I'm done dickin' around.

Will update as things go along. Ill still clean it some more above and grease it well with install.

Last edited:

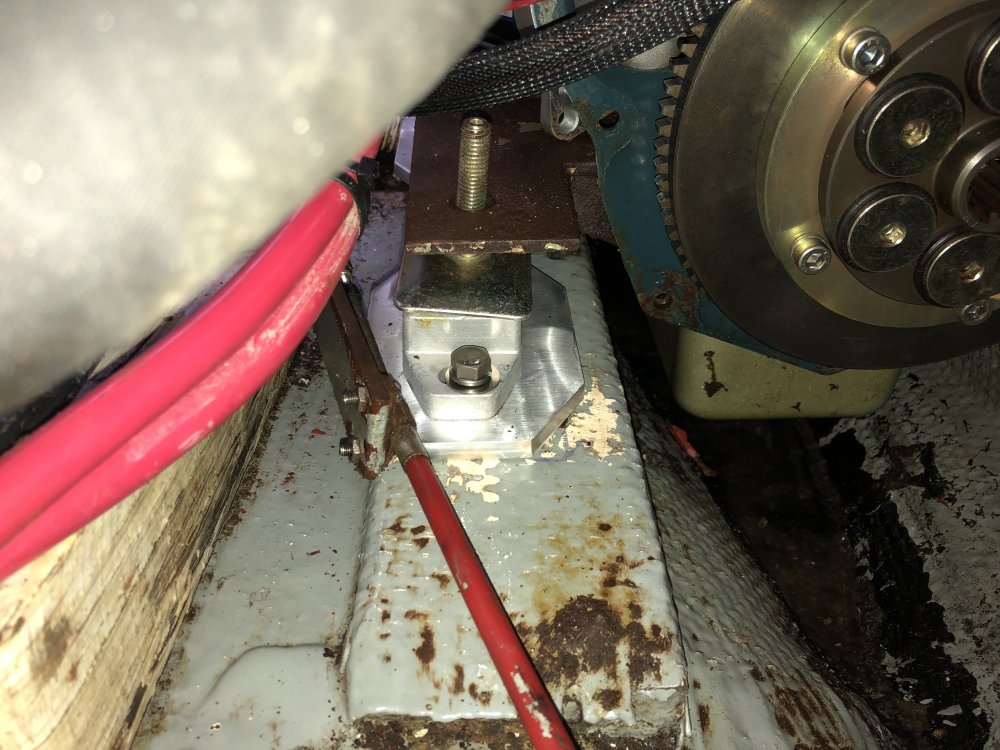

Went up today and added 3/8” aluminum shims and new motor mounts.

Found 3/8” lags that are just right at Fastenal this afternoon. Got the last ones, just enough. All lags bit well, except for 1 on the forward starboard mount. Did tighten, just not as good the rear.

Got a friend to help with bell housing tomorrow. I was not brave enough to loosen the dripless. When I touch the seal it leaks, a lot. I’m going to have to loosen tomorrow and slide back, but I’m chicken, it looks old.

Found 3/8” lags that are just right at Fastenal this afternoon. Got the last ones, just enough. All lags bit well, except for 1 on the forward starboard mount. Did tighten, just not as good the rear.

Got a friend to help with bell housing tomorrow. I was not brave enough to loosen the dripless. When I touch the seal it leaks, a lot. I’m going to have to loosen tomorrow and slide back, but I’m chicken, it looks old.

Your story hits too close to home. Every project I do slowly seems to go in the crapper (sigh). It is always something. Keep at it. It's nice to see this stuff happens to others too. My fingers are crossed for you. I'm currently trying to fix our shower door and I just know it will snowball into a bathroom remodel.

We feel your pain! Fwiw, I used Federal Marine Supply in Illinois for genuine ZF Factory parts to rebuild my HBW50 transmission 2 winters ago(it did take 6 weeks to get the parts shipped from Italy). total cost with new damper was approximately $700. They may be able to help you with that damper plate but it sounds like its not a very common engine setup.

This morning we got the bell housing and transmission in place, undid dripless seal before, and did coupling attachment. I was not too afraid of the dripless after I re-read instructions and realized that there are 2 set screws, no wonder I was fighting it, then I realized that I had to load the bellows with water came puring in, I will admit I had a minor panic attack, but it worked great! I tried to get the marine mechanic to align shaft, but I was told at least 2 weeks. Screw it.....I am sick of waiting. Surprisingly when I did coupler it was pretty close to right on. I spent 30 min getting it aligned, which was pretty good once I realized I had coupler on backwards and spent another 20 min getting it up and turned around. It slid together really nice........WTF? Where is Murphy?

As I began to get excited...I started the engine. And that bastard Murphy struck!

Black oil began to pour into the bilge!! OMG, thank God I realized and got up to kill engine quickly, I bet a quart at least was in the bilge!

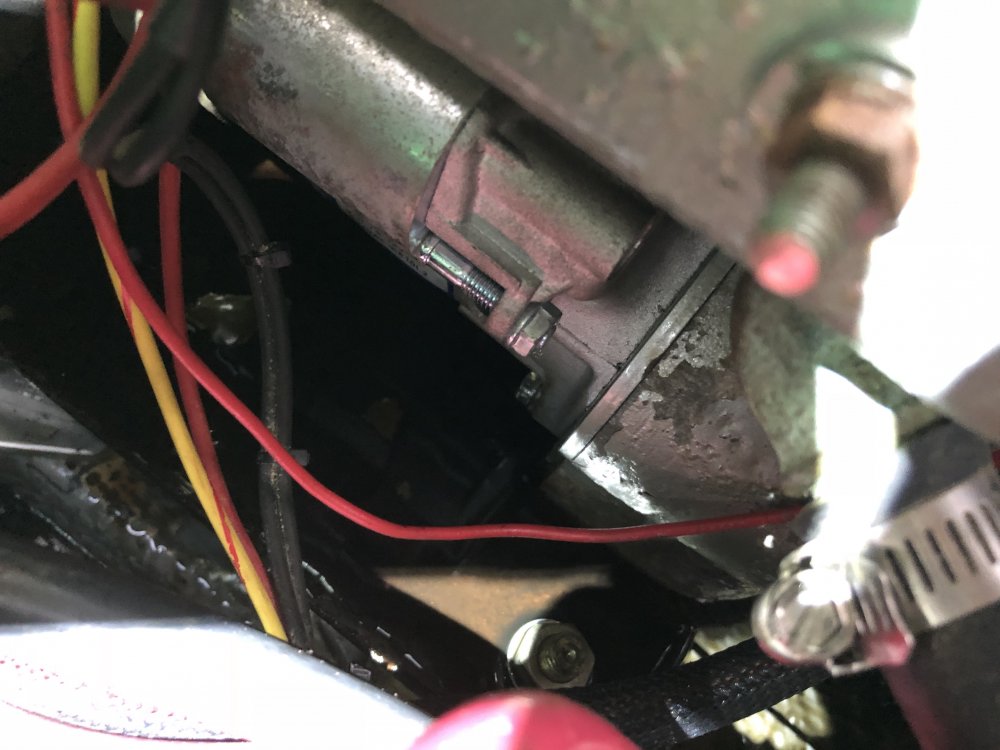

During the install of the starter, since I did not remove the heat exchanger, we must have stress weakened the oil pressure sensor couple which was brass 1/8" threaded pipe. I lost my mind, I walked hard, I threw thinks in the water, I threw things in the boat, I almost cried when I realized that this is just another obstacle and I got through the last 12 with this dang thing. Peace....a funny thing.

Got an easy out and got piece out of fitting, found 1/8 inch threaded nipple on both ends at Lowe's, and going up tomorrow to suck oil from bilge and reattach. I am going to try the first engagement of tranny tomorrow after I top up the oil. Added can of beer to the pondering.

As I began to get excited...I started the engine. And that bastard Murphy struck!

Black oil began to pour into the bilge!! OMG, thank God I realized and got up to kill engine quickly, I bet a quart at least was in the bilge!

During the install of the starter, since I did not remove the heat exchanger, we must have stress weakened the oil pressure sensor couple which was brass 1/8" threaded pipe. I lost my mind, I walked hard, I threw thinks in the water, I threw things in the boat, I almost cried when I realized that this is just another obstacle and I got through the last 12 with this dang thing. Peace....a funny thing.

Got an easy out and got piece out of fitting, found 1/8 inch threaded nipple on both ends at Lowe's, and going up tomorrow to suck oil from bilge and reattach. I am going to try the first engagement of tranny tomorrow after I top up the oil. Added can of beer to the pondering.

Having that much weight hanging off the 1/8 nipple with the vibration of a diesel is asking for trouble, it’s going to break there again.

They make dual switch/sensor oil pressure transducers. VDO 360009. 0-80 gauge 6psi alarm. Amazon has them for $45

They make dual switch/sensor oil pressure transducers. VDO 360009. 0-80 gauge 6psi alarm. Amazon has them for $45

Thanks for the advice and part number, I ordered it on Amazon, won't be here until next week. Hopefully using the easy out to get the broken end out did not bugger the threads. The one I put in leaked until I used teflon tape and tightened it down pretty hard. That would only be another Murphy moment when new part comes in. . I can't worry about that now. The gearbox thing worked. I went back and tried to get feeler gauges to align shaft a little better, maybe yes, maybe no. Seems like there is a lot of vibration and the shift does not feel velvety smooth, but that may just be the newness of box. I also tried to hook up the mount for the shifter, of course I did not bring my drill and the mounting holes for shift cable were too close together and really rusted on. When I went to start the engine after more diddling with mounts, the solenoid would fire but not engage flywheel. OMG, this thing is killing me. I don't know if I dislodged wiring or what, it was working fine when I started. I wanted to just cry. I cleaned 2 quarts of oil out of the bilge using "environmentally sound" practices with absorbent material the marina guys sold. The bilge was a years worth of sludge, stinky oil, and disgusting chunks of something. After that, I just wanted to cry. My neighbor Nate who helped me do install, gave me a present when I got home. I paired it with a beer.........eerily appropriate.

Last edited:

Here is You tube vid of engine first run. Can I just say how much I like this new tech? I am loving the air drop from my Iphone. In watching the vid, that was before I went back and did some more adjustments. Im not sure...I wish I had some reasonable options to have back up on adjustments.

Last edited:

I was so frustrated....I did not. Im going up today to put on new part for pressure sensor, drill out mount and attach shift controls, and see if I can get someone help me with solenoid. I think when oil leaked from pressure sensor nipple, it may have poured into the starter and solenoid. Im betting based on how this goes, I will be ordering new starter and solenoid? I was going to post an update tonight, I just needed a mental break. I was so focused & engaged that I made myself overtired and sick.

Sorry to hear that man. Take your time. Do it right. I know you're focused on the goal. But, better to do it right the first time than to have to do the job twice. Hang in there!I was so frustrated....I did not. Im going up today to put on new part for pressure sensor, drill out mount and attach shift controls, and see if I can get someone help me with solenoid. I think when oil leaked from pressure sensor nipple, it may have poured into the starter and solenoid. Im betting based on how this goes, I will be ordering new starter and solenoid? I was going to post an update tonight, I just needed a mental break. I was so focused & engaged that I made myself overtired and sick.