Best inverter for the buck

- Thread starter prroots

- Start date

- Status

- Not open for further replies.

Thanks right on! Here is a quote from:Blue Seas disagrees with those numbers.

http://bluesea.com/files/resources/...ical Brief_Select_a_Fuse_and_a_Fuse_Block.pdf

The manufacturer recommended 250 Amps which is less than recommended by the above source (the table from the above link states that a class ANL 300 Amp fuse is sufficient to protect 2/0 cable passing through engine room or 350 Amps otherwise).In some cases, a product manufacturer will specify a fuse value. Use that value if it is under maximum allowed by the wire.

Pete

Bill,And depending on the type I get the max current for 2/O as;

TW UF ---145 amps

RHW/THW ---175 amps

TBS/SA/SIS ---195 amps

so the wires melt first and then the fuse blows..... It is just a matter of time

http://www.armstrongssupply.com/wire_chart.htm

From Doctrine Man on Clausewitz

Experience is something you don't get until just after you need it most.

and

No plan is fool proof when executed by a sufficiently demented fool.

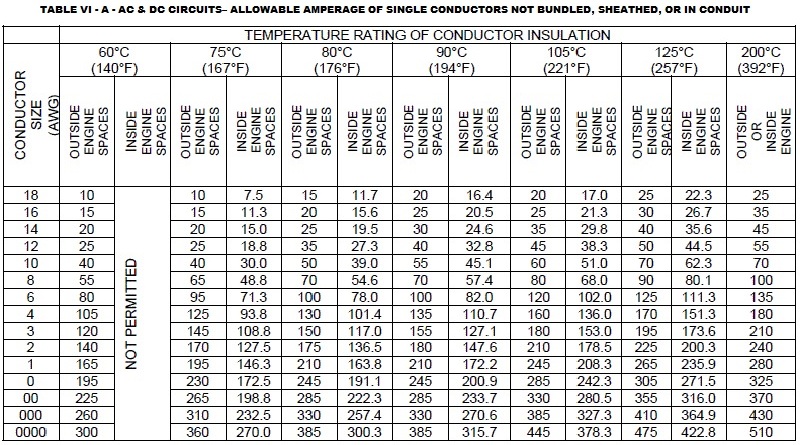

Max ampacity for fusing 2/0 105C wire when run as a single conductor is:

280.5 Amps - Inside an engine space

or

330 Amps - Outside of an engine space

Pete has a 250A ANL which is below both allowable ranges.

This is the ABYC max allowable ampacity chart.

Pete

It is your boat.

The question is are you going to believe the NEC or West Marine

http://en.wikipedia.org/wiki/National_Electrical_Code

Please check the cables for overheat while doing your tests.

It is your boat.

The question is are you going to believe the NEC or West Marine

http://en.wikipedia.org/wiki/National_Electrical_Code

Please check the cables for overheat while doing your tests.

I believe we would need to know the type of wire specifically to acertain wither or not Pete will be needing a fire extinguisher.

Even the ABYC shows 225 amps max for a 140F wire temp.

All this begs the question, what does it say on the insulator. Untill you know and in this case make a decision on the max temp you are willing to have you don't know do you?

the Great Roosak thinks it prudent to not let wires get "hot to the touch". It promotes corrosion, fires, loosens up connectors of all types....... it is not good engineering practice to use 1 (aka "none") as a safety factor. Given this is a high power, high amp circuit it is even more important to have some additional buffer so the circuit never sees a max load.

But Pete, it is your boat.

Max Ampacity is just that the max with no safety factor. You can surge to this level but go even slightly over it and you will begin to see bad things happen.

Even the ABYC shows 225 amps max for a 140F wire temp.

All this begs the question, what does it say on the insulator. Untill you know and in this case make a decision on the max temp you are willing to have you don't know do you?

the Great Roosak thinks it prudent to not let wires get "hot to the touch". It promotes corrosion, fires, loosens up connectors of all types....... it is not good engineering practice to use 1 (aka "none") as a safety factor. Given this is a high power, high amp circuit it is even more important to have some additional buffer so the circuit never sees a max load.

But Pete, it is your boat.

Max Ampacity is just that the max with no safety factor. You can surge to this level but go even slightly over it and you will begin to see bad things happen.

Also;

is that a fast or slow blow 250 amp fuse?

betcha it is a slow blow and can run at 120% for about 5 minutes before it blows........ Dang safety factors always keeping us out of danger.

Danger is Pete's middle name you know.

Great googly moogley Pete please check this stuff out and make it right. I do not want to read on this post that something tragic happened.

is that a fast or slow blow 250 amp fuse?

betcha it is a slow blow and can run at 120% for about 5 minutes before it blows........ Dang safety factors always keeping us out of danger.

Danger is Pete's middle name you know.

Great googly moogley Pete please check this stuff out and make it right. I do not want to read on this post that something tragic happened.

Bill,Also;

is that a fast or slow blow 250 amp fuse?

betcha it is a slow blow and can run at 120% for about 5 minutes before it blows........ Dang safety factors always keeping us out of danger.

Danger is Pete's middle name you know.

Great googly moogley Pete please check this stuff out and make it right. I do not want to read on this post that something tragic happened.

All of this PLUS a 150% factor is already taken into account in ABYC Table IV. I prefer to fuse at 100% or less, as table IV shows, but you are allowed to fuse to 150% of table IV ampacity and fuse blow times are already accounted for in ABYC Table IV. Remember this is NOT nominal current it is the max ampacity for fusing..

The dead short in the wire below was 2 GA, with an owner installed 300A fuse, inside an engine compartment. Max ampacity at 100% of table IV in an engien bay is 178A. This however was not 105C wire and was likely 90C, at best.

I'd have to say that in the "real world", not "Great Roosaks" world, the ABYC safety parameters do work.. This fuse was well ABOVE the 150% rule and the wire did NOT catch fire. The 300A fuse safely blew as it should. Working on boats I have blown a number of $15.00 fuses and never had any "wire damage". Always sucks when I do that, cause I eat that fuse as I should, but they blow, as they should, even when sized at 150% of Table IV. There was nothing more than some slight heat discoloration near the short, as can be seen, and nothing else.

Real world exceeding the max ampacity of Table IV allowances:

With a voltage drop less than 3% or 0.28V drop at 11.98V = 2.35% VD @ 127A of current that wire should be running at nearly the same temp as ambient.

Really?

So running your cables at above the boiling point for water is a good idea?

Let me ask you MS, if you were running your microwave at home and you somehow managed to feel the power supply cord and it was "burning hot" but not smoking what would you do? I know what my First Mate would do and she does not have an engineering degree.

In the interest of having a second opinion let me do some checking tonight on the actual spec sheets for all this stuff and give you my "reasoned" answer.

Specifically: given a 1900 watt inverter what size fuse and wire should you use? Note the “should” Account for the 3% voltage drop, single run wires (no bundles) and a maximum run time of 5 minutes and complete cooling between runs. The run length is 4 foot round trip and we will assume that the cables are terminated properly and in accordance with best practices. Since we are having an issue with proper temp to run thing at, I’ll just quote the wire size vs temp after 5 minutes and cooling time and let the group determine what “should” be used.

My gut feeling is the ABYC is correct but that is just what you CAN get away with. It does not mean you should design it to operate that way. I’d note that you can’t specify a standard with anything but a safety factor of 1 and it is up to the engineers to ensure that the specific install is in fact safe to operate as designed.

BTW at 0.29 volt drop and 127 amps you have 37 watts being dissipated / 4 foot of cable. So 9 watts/foot. It does not sound like much but wire has this really nasty property of being a poor heat dissipater. Betcha those wires are somewhat more than ambient after 4 minutes of operation.

So running your cables at above the boiling point for water is a good idea?

Let me ask you MS, if you were running your microwave at home and you somehow managed to feel the power supply cord and it was "burning hot" but not smoking what would you do? I know what my First Mate would do and she does not have an engineering degree.

In the interest of having a second opinion let me do some checking tonight on the actual spec sheets for all this stuff and give you my "reasoned" answer.

Specifically: given a 1900 watt inverter what size fuse and wire should you use? Note the “should” Account for the 3% voltage drop, single run wires (no bundles) and a maximum run time of 5 minutes and complete cooling between runs. The run length is 4 foot round trip and we will assume that the cables are terminated properly and in accordance with best practices. Since we are having an issue with proper temp to run thing at, I’ll just quote the wire size vs temp after 5 minutes and cooling time and let the group determine what “should” be used.

My gut feeling is the ABYC is correct but that is just what you CAN get away with. It does not mean you should design it to operate that way. I’d note that you can’t specify a standard with anything but a safety factor of 1 and it is up to the engineers to ensure that the specific install is in fact safe to operate as designed.

BTW at 0.29 volt drop and 127 amps you have 37 watts being dissipated / 4 foot of cable. So 9 watts/foot. It does not sound like much but wire has this really nasty property of being a poor heat dissipater. Betcha those wires are somewhat more than ambient after 4 minutes of operation.

Really?

So running your cables at above the boiling point for water is a good idea?

Let me ask you MS, if you were running your microwave at home and you somehow managed to feel the power supply cord and it was "burning hot" but not smoking what would you do? I know what my First Mate would do and she does not have an engineering degree.

In the interest of having a second opinion let me do some checking tonight on the actual spec sheets for all this stuff and give you my "reasoned" answer.

Specifically: given a 1900 watt inverter what size fuse and wire should you use? Note the “should” Account for the 3% voltage drop, single run wires (no bundles) and a maximum run time of 5 minutes and complete cooling between runs. The run length is 4 foot round trip and we will assume that the cables are terminated properly and in accordance with best practices. Since we are having an issue with proper temp to run thing at, I’ll just quote the wire size vs temp after 5 minutes and cooling time and let the group determine what “should” be used.

My gut feeling is the ABYC is correct but that is just what you CAN get away with. It does not mean you should design it to operate that way. I’d note that you can’t specify a standard with anything but a safety factor of 1 and it is up to the engineers to ensure that the specific install is in fact safe to operate as designed.

BTW at 0.29 volt drop and 127 amps you have 37 watts being dissipated / 4 foot of cable. So 9 watts/foot. It does not sound like much but wire has this really nasty property of being a poor heat dissipater. Betcha those wires are somewhat more than ambient after 4 minutes of operation.

Bill,

The 250A fuse is there ONLY to protect the wire NOT the inverter. It is currently sized well blow the ABYC Table IV max ampacity ratings. It is also sized to the MANUFACTURERS suggestion. Perhaps your second guessing should be with Xantrex and the ABYC. I am sure they are willing to listen to you edumacate them..

Pete's voltage drop is also LESS, based on what he has provided us with, than what the manufacturer suggests. Xantrex allows for 0.03V per foot Pete is at 0.024V per foot.

Lets take a worst case scenario of 3000W surge or 300A. (continuous is only 1800W)

Pete claims to have 8' of 2/0 wire BUT is using two different meters, with limited accuracy, to determine his VD. I suspect he has LESS than 0.28V unless he has more wire than we know about.. Even still at his face value numbers he has less than 3% VD.

The basic voltage drop math shows us:

300A over 8' of 2/0 wire & a 12 volt starting point yields a voltage drop of 0.192 volts or a 1.6% voltage drop. 1.6% VD is a dream on boats. I REGULARLY measure alternator circuits with 5% VD or more. I have yet to see a "melted jacket" due to voltage drops below 10%..

The ABYC standards allow for up to 10% voltage drop in "non critical" systems eg: not nav lights, VHF etc. etc. and mandate 3% for "critical" systems. A 1.6% voltage drop is quite good in any 12V system.

You have an inverter. What is the gauge of your wire and what is the wattage of your inverter? Perhaps a picture of it would help? What are the wire lengths round trip?

Boiling water with a 1.6% voltage drop, really? Is it 5:00 somewhere???

The modern practice is to use 105C-rated cables, and he is 2/0, not #2....Even the ABYC shows 225 amps max for a 140F wire temp.....

A 2/O copper cable has the following properties:

0.0000779 ohms/ft resistance

402.83 lb/ 1000 ft of cable or 0.402 lb /ft

The specific heat of copper is .0923 BTU/(lb*F)

Not very useful units as we are doing electricity and everything is in

watts.

1 watt = 3.414 BTU/hour which would lead us to believe

1 watt*hour = 3.414 BTU

And

The specific heat of copper is 0.0923 BTU/(lb*F) or 0.02704 Watt*hour/(lb*F)

A 1800 Watt inverter at 12 volts would draw 150 amps continuous

Power = IV = I^2*R

The power dissipated per unit foot by the cable resistance would be

Pd = 150*150*0.0000779= 1.75 watts/ft

Sense we all remember from thermodynamics class that the change in temp is

equal to the amount of heat you add divided by the product of the mass and

the specific heat or

Delta T = delta Q /(mass*c) and remembering this is for a unit length of

wire we get

Delta T = 1.75 (watts/(ft*sec))/(0.40283 (lb/ft)*0.02703(watts*hours)/(lb*F)

= 161 F temp change per hour. This ignores any cooling due to convection,

radiation etc.

But we did not run the inverter for an hour we only ran it for 5/60th hours

so 161*5/60=13.4 degrees

And Bill is now eating crow

But doing it in a boat that we know will not heat the wires to melting point

Alternately you would have to (again ignoring cooling) run the wires for (105 C is approx 220 F) 220/161=1.3 hours before you could even hope to see any problem

So the inverter should be fine as long as the cable does not short which brings up my first point. Will the slow blow 150% overrated 250 amp fuse blow before the wire melts. The diagram of the time to blow vs amps for the ANL fuse shows that it will sustain a 150% load or 1.5*250=375amps load for at least 500 seconds. I’m not getting the impression that it will ever blow below that as the curve is logarithmic and the slope is flat. Doing the wire heat thing again for 375 amps we get

Pd=375*375*0.0000779= 10.95 watts/ft

Delta T = 10.95/(0.40283*0.02703)=1006 F/hour temp change since we can surmise that if it gets that hot it will fail and 105 is the max then the cable should fail 220F/1006=0.22 hours or 13 minutes.

So I guess what I’m saying is that this cable can carry 150% above its maximum current and the fuse will not blow but the cable insulation will melt as you would expect. I personally would not design a circuit that can be loaded by the next owner in such a fashion. If you short the cable and pass 1000+ amps then the fuse will blow and if you kept the current down below the maximum rating for the fuse 250 you would be fine. Course most of us don’t have a clue how much current is actually passing so you are left to wonder what the next owner or your brother-in-law might do.

Does following the ABYC and manufacturer’s rating work? Yes provided you don’t add some additional loads later.

0.0000779 ohms/ft resistance

402.83 lb/ 1000 ft of cable or 0.402 lb /ft

The specific heat of copper is .0923 BTU/(lb*F)

Not very useful units as we are doing electricity and everything is in

watts.

1 watt = 3.414 BTU/hour which would lead us to believe

1 watt*hour = 3.414 BTU

And

The specific heat of copper is 0.0923 BTU/(lb*F) or 0.02704 Watt*hour/(lb*F)

A 1800 Watt inverter at 12 volts would draw 150 amps continuous

Power = IV = I^2*R

The power dissipated per unit foot by the cable resistance would be

Pd = 150*150*0.0000779= 1.75 watts/ft

Sense we all remember from thermodynamics class that the change in temp is

equal to the amount of heat you add divided by the product of the mass and

the specific heat or

Delta T = delta Q /(mass*c) and remembering this is for a unit length of

wire we get

Delta T = 1.75 (watts/(ft*sec))/(0.40283 (lb/ft)*0.02703(watts*hours)/(lb*F)

= 161 F temp change per hour. This ignores any cooling due to convection,

radiation etc.

But we did not run the inverter for an hour we only ran it for 5/60th hours

so 161*5/60=13.4 degrees

And Bill is now eating crow

But doing it in a boat that we know will not heat the wires to melting point

Alternately you would have to (again ignoring cooling) run the wires for (105 C is approx 220 F) 220/161=1.3 hours before you could even hope to see any problem

So the inverter should be fine as long as the cable does not short which brings up my first point. Will the slow blow 150% overrated 250 amp fuse blow before the wire melts. The diagram of the time to blow vs amps for the ANL fuse shows that it will sustain a 150% load or 1.5*250=375amps load for at least 500 seconds. I’m not getting the impression that it will ever blow below that as the curve is logarithmic and the slope is flat. Doing the wire heat thing again for 375 amps we get

Pd=375*375*0.0000779= 10.95 watts/ft

Delta T = 10.95/(0.40283*0.02703)=1006 F/hour temp change since we can surmise that if it gets that hot it will fail and 105 is the max then the cable should fail 220F/1006=0.22 hours or 13 minutes.

So I guess what I’m saying is that this cable can carry 150% above its maximum current and the fuse will not blow but the cable insulation will melt as you would expect. I personally would not design a circuit that can be loaded by the next owner in such a fashion. If you short the cable and pass 1000+ amps then the fuse will blow and if you kept the current down below the maximum rating for the fuse 250 you would be fine. Course most of us don’t have a clue how much current is actually passing so you are left to wonder what the next owner or your brother-in-law might do.

Does following the ABYC and manufacturer’s rating work? Yes provided you don’t add some additional loads later.

I've been using my inverter now for over a week. As mentioned, the first phase uses it in a standalone mode with extension cord to power AC devices. We've used it for microwave, coffee grinder, power drill, etc. Given our infrequent usage overall, there seems little motivation at this point to move to phase two, the integration into existing AC system.

Pete

Pete

I like simpleI've been using my inverter now for over a week. As mentioned, the first phase uses it in a standalone mode with extension cord to power AC devices. We've used it for microwave, coffee grinder, power drill, etc. Given our infrequent usage overall, there seems little motivation at this point to move to phase two, the integration into existing AC system.

Pete

Sum

[FONT=Arial, sans-serif]Our Endeavour 37[/FONT]

[FONT=Arial, sans-serif]Our Trips to Utah, Idaho, Canada, Florida[/FONT]

[FONT=Arial, sans-serif]Our MacGregor S Pages[/FONT]

[FONT=Arial, sans-serif]Mac-Venture Links[/FONT]

- Status

- Not open for further replies.