I've actually contemplated (for 5 seconds) a $5,000.00 compact roller swager (yeah right-- maybe I'll start a second career as a C-22 rigger-- BUT in the process I stumbled across these mechanical (bonus; removable for repair/inspection) fittings in 316.

Anyone played with these? I'm going in......

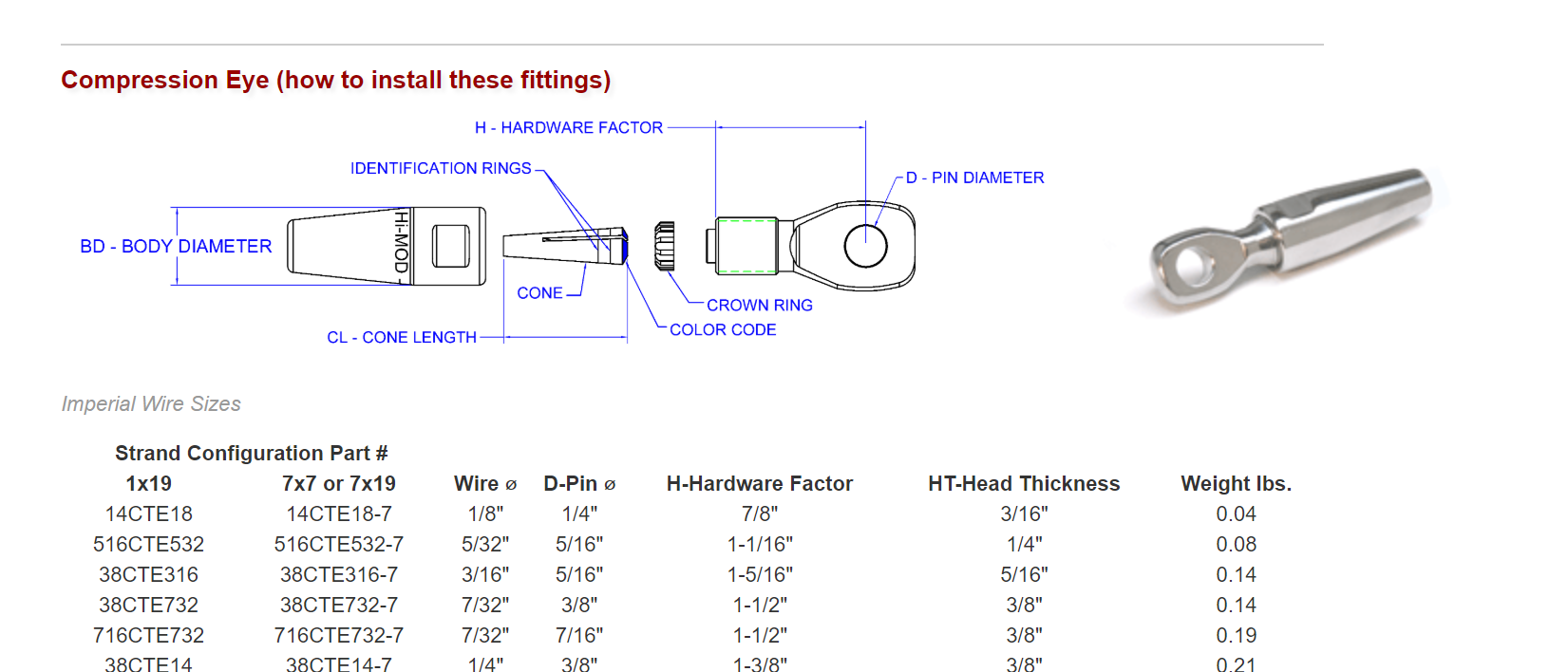

Hi-MOD Fittings by Hayn Marine

Anyone played with these? I'm going in......

Hi-MOD Fittings by Hayn Marine