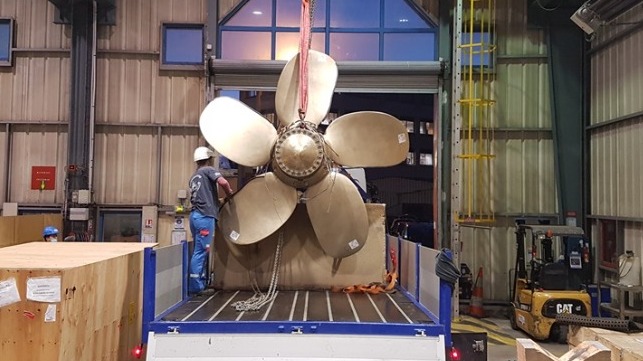

Coincidentally, just after I posted here about the 3D printed propeller a new Sam Holmes Sailing on youtube vid popped up.

And what do you know? it's 3d printing.

I get the feeling that this technology is maturing really fast.

And what do you know? it's 3d printing.

I get the feeling that this technology is maturing really fast.