Repairing Hunter 40 damage from Hurricane Matthew

- Thread starter B757Captain

- Start date

You’ll find a way to make it interesting. I have complete faith in you.Hmmm - how to spice up a battery box?

So, almost two years in, .....

Wow, it really has been that long. any glimpse of an end in sight?

Looking at the speed of progress, you're what? A year out yet?

What an amazing journey,

Wow, it really has been that long. any glimpse of an end in sight?

Looking at the speed of progress, you're what? A year out yet?

What an amazing journey,

The Fireflys were pre-damage. I had installed them (with an all new charging system) less than two months prior to Matthew. Of course the submersion ruined them but I kept the batteries for the purpose of mock-up when building the new battery box. I finally took the poor batteries to the scrapper before returning to Japan. That actually is one of the biggest personal hurt factors of the whole deal. I never got to really use them.Are these AGM or flooded?

Were these pre-damage or new?

They are AGMs, and at the risk of making a fool of myself in the explanation, here's why they are better: the plate separators are a carbon foam instead of fiberglass as in normal AGMs. I don't pretend to understand for sure but near as I can tell by reading and inferring, the carbon foam (perhaps by bonding to the lead plates?) prevents lead sulfate buildup. That means no need for equalization, and the normal flooded/AGM limit of max 50% depletion also does not apply. They can be discharged to 20% capacity (testing by Mainsail and others have gone below that) and recovered repeatedly, they do not need to be fully charged - due to no sulfation - so most of the battery maintenance we have come to love is not needed. That was my justification for the extra cost. And boy, was it sticker shock at the time!

Good news is that the prices have gone up since I bought the last set. Yay!

I think just over two years now. Hard to believe, but what is harder to believe is we still have no progress on the marina being rebuilt! Works for me but sucks for everyone else on the island.So, almost two years in, .....

Wow, it really has been that long. any glimpse of an end in sight?

Looking at the speed of progress, you're what? A year out yet?

What an amazing journey,

I would guess more than a year from completion. I don't yet have an accurate gauge of how much I can expect to get done on my leave periods - the last two times home were weird for various reasons

Just checking back after a while away. Keep sluggin' BCap. I sold our beloved Dawn Treader - and she survived a direct hit in New Bern with her new owners...this after surviving a direct hit from Irma while we had her on the hard in FL. These Hunters are tough as hell!

Thanks smackdaddy! Glad to hear your (their) boat survived - it seems so hit&miss sometimes.Just checking back after a while away. Keep sluggin' BCap. I sold our beloved Dawn Treader - and she survived a direct hit in New Bern with her new owners...this after surviving a direct hit from Irma while we had her on the hard in FL. These Hunters are tough as hell!

The countdown to repair-a-palooza is on! November schedule is confirmed, flight is booked, I should be home Saturday! Of course tons of projects still to go but I have several on top of the list. Depends on the weather as to if the outside or below-deck projects get done, or combination thereof. I'll dig up my old list for reference, itemize it so it's not in any particular order (hat tip Kermie!!), add the things I've been brainstorming for the last 6 weeks and see where it goes. Stay tuned!

Cheers,

Mark san

Last edited:

Home at last!

Evening, gents. In reality I've been home for a week but between jetlag, honey-dos, boat projects and setting up a new computer this is the first opportunity I've had to post an update. So here goes:

For the first (and only time in 2018) the flight home went without a hitch! Departed on time, landed on time, all connections as booked. Yay! I hate being SLF, obviously I'd rather be up front but at least this time it worked. First job after "feet dry" was to open all the boxes of goodies. Most important was the new laptop I'm pounding on - the old one was on it's last legs. I can't complain, I bought it before leaving for Ethiopia in 2014 and it has literally been around the world. Multiple times! The replacement is just a newer version, why mess with success

Then out to the boat. I have to admit that I probably was a little optimistic with my list of things the last few times home so this time I'll keep the project list reasonable. If I can go farther, great. Since I have (mostly) warm(ish) weather this time around I wanted to get to a few projects on deck:

First up, removing the old windlass:

I know, that's not a pic of the deck! But I have wanted to find a better way of dealing with anchoring and I'm convinced that whoever set up this windlass never actually dropped or retrieved an anchor. Ever! Thus after getting the boat back on the hard I neglected to do anything with the windlass. After it comes out there will be a hole in the deck to deal with, and since I had already filled the holes from the foot controls I will have three repair spots to cover on deck. Stay tuned!

Next, replacing/upgrading the handrails on deck:

There are two rails per side, and they are the last bits of teak left topsides. Since I have no desire at all to maintain teak, the obvious solution is to replace them with stainless. Parts ordered and on the way.

As a consequence of repairing/filling holes on deck, I will continue with the KiwiGrip non-skid application. I had finished about half of the deck pre-Matthew so this time around I should make a pretty good dent in what remains.

During the times I can't work on deck, i.e., raining or dark, I'll work on this:

Starboard pantry/storage locker and hanging locker. I'm going to do some modifications to the old cabinetry. The pantry was originally a cooler that I converted, which worked well except that it was too deep! So the plan is to recess the pantry some. I'm thinking the hanging locker was ok the way it was so for that it will be copying the old pieces.

Lastly, if I have time, the port side aft cabin lockers:

I had to cut the old piece into two segments for it to fit thru the companionway. Since this side belongs to the admiral, I'm thinking of adding to the hanging locker. That will segment the piece so no issues with getting it onboard.

That's it for now!

Cheers,

Mark san

Evening, gents. In reality I've been home for a week but between jetlag, honey-dos, boat projects and setting up a new computer this is the first opportunity I've had to post an update. So here goes:

For the first (and only time in 2018) the flight home went without a hitch! Departed on time, landed on time, all connections as booked. Yay! I hate being SLF, obviously I'd rather be up front but at least this time it worked. First job after "feet dry" was to open all the boxes of goodies. Most important was the new laptop I'm pounding on - the old one was on it's last legs. I can't complain, I bought it before leaving for Ethiopia in 2014 and it has literally been around the world. Multiple times! The replacement is just a newer version, why mess with success

Then out to the boat. I have to admit that I probably was a little optimistic with my list of things the last few times home so this time I'll keep the project list reasonable. If I can go farther, great. Since I have (mostly) warm(ish) weather this time around I wanted to get to a few projects on deck:

First up, removing the old windlass:

I know, that's not a pic of the deck! But I have wanted to find a better way of dealing with anchoring and I'm convinced that whoever set up this windlass never actually dropped or retrieved an anchor. Ever! Thus after getting the boat back on the hard I neglected to do anything with the windlass. After it comes out there will be a hole in the deck to deal with, and since I had already filled the holes from the foot controls I will have three repair spots to cover on deck. Stay tuned!

Next, replacing/upgrading the handrails on deck:

There are two rails per side, and they are the last bits of teak left topsides. Since I have no desire at all to maintain teak, the obvious solution is to replace them with stainless. Parts ordered and on the way.

As a consequence of repairing/filling holes on deck, I will continue with the KiwiGrip non-skid application. I had finished about half of the deck pre-Matthew so this time around I should make a pretty good dent in what remains.

During the times I can't work on deck, i.e., raining or dark, I'll work on this:

Starboard pantry/storage locker and hanging locker. I'm going to do some modifications to the old cabinetry. The pantry was originally a cooler that I converted, which worked well except that it was too deep! So the plan is to recess the pantry some. I'm thinking the hanging locker was ok the way it was so for that it will be copying the old pieces.

Lastly, if I have time, the port side aft cabin lockers:

I had to cut the old piece into two segments for it to fit thru the companionway. Since this side belongs to the admiral, I'm thinking of adding to the hanging locker. That will segment the piece so no issues with getting it onboard.

That's it for now!

Cheers,

Mark san

Not sure what you do to "maintain" Teak.Normally, you just let it be. Many boats have Mahogany which is cheaper and doesn't last as long. My last boat I built rails out of Cumaru. It is very oily and is one of the toughest woods that won't break the bank. You can not put screws in it, it must be drilled. (I snapped a screw off trying). I built the grab rails from 1 piece of decking plank. I could have probably lifted the boat with it.Since I have no desire at all to maintain teak...

I always thought teak maintenance would include either frequent, semi-frequent, or in my case, very infrequent re-applications of varnish or teak oil. The rails are so far gone that the wood is splitting so I have to either get new wood rails or switch to stainless. I already have stainless rails on the swim platform so I'm going with the same for the cabin top.Not sure what you do to "maintain" Teak.Normally, you just let it be. Many boats have Mahogany which is cheaper and doesn't last as long. My last boat I built rails out of Cumaru. It is very oily and is one of the toughest woods that won't break the bank. You can not put screws in it, it must be drilled. (I snapped a screw off trying). I built the grab rails from 1 piece of decking plank. I could have probably lifted the boat with it.

The Windlass:

Since I had always intended to replace/re-engineer the windlass and anchoring setup, I neglected to do anything with it after raising the boat. Over time, I thought about removing it but had a nagging idea that it was probably corroded and would be hard to deal with. Not the case! First up was to remove the 4 bolts on the bottom - no problem. What next? It turns but won't separate. I never got any documentation for the windlass when I bought the boat, so the internet to the rescue!

The windlass is a Lofrans Progress 1. Obviously long out of production but I did find a site that had a manual for it. Big letdown except it had an exploded parts diagram which did the trick:

The capstan(?) initially didn't want to budge but since it was destined for the trash - out with the BFH. It budged! Next off was the gypsy, three snap rings and a few taps and then a big bang as the bottom part fell out and dropped to the floor. A little prying on the top half to break loose the sealant and it's cleanup time. After scraping and sanding I cut a plug and epoxied it in:

The weird looking thing is a freezer bag filled with thickened epoxy. Learned that trick from watching Mads on the SailLife videos. Fill the baggie with thickened epoxy, snip off the tip and squeeze. Perfect for filling gaps! As an aside, I highly recommend watching SailLife on Youtube. The guy's name is Mads, lives in Denmark and is doing an extensive refit on a Warrior 38. Good stuff!

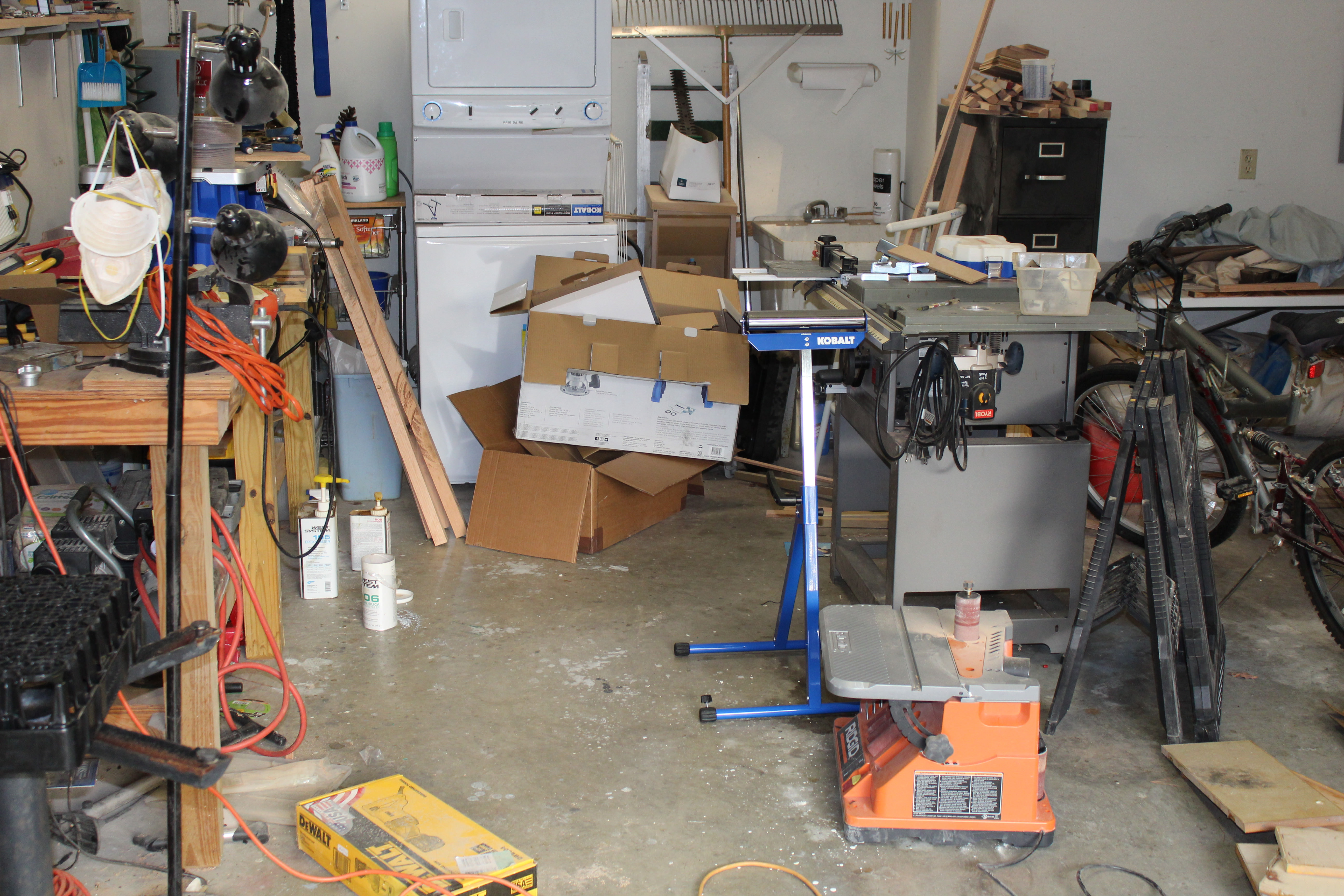

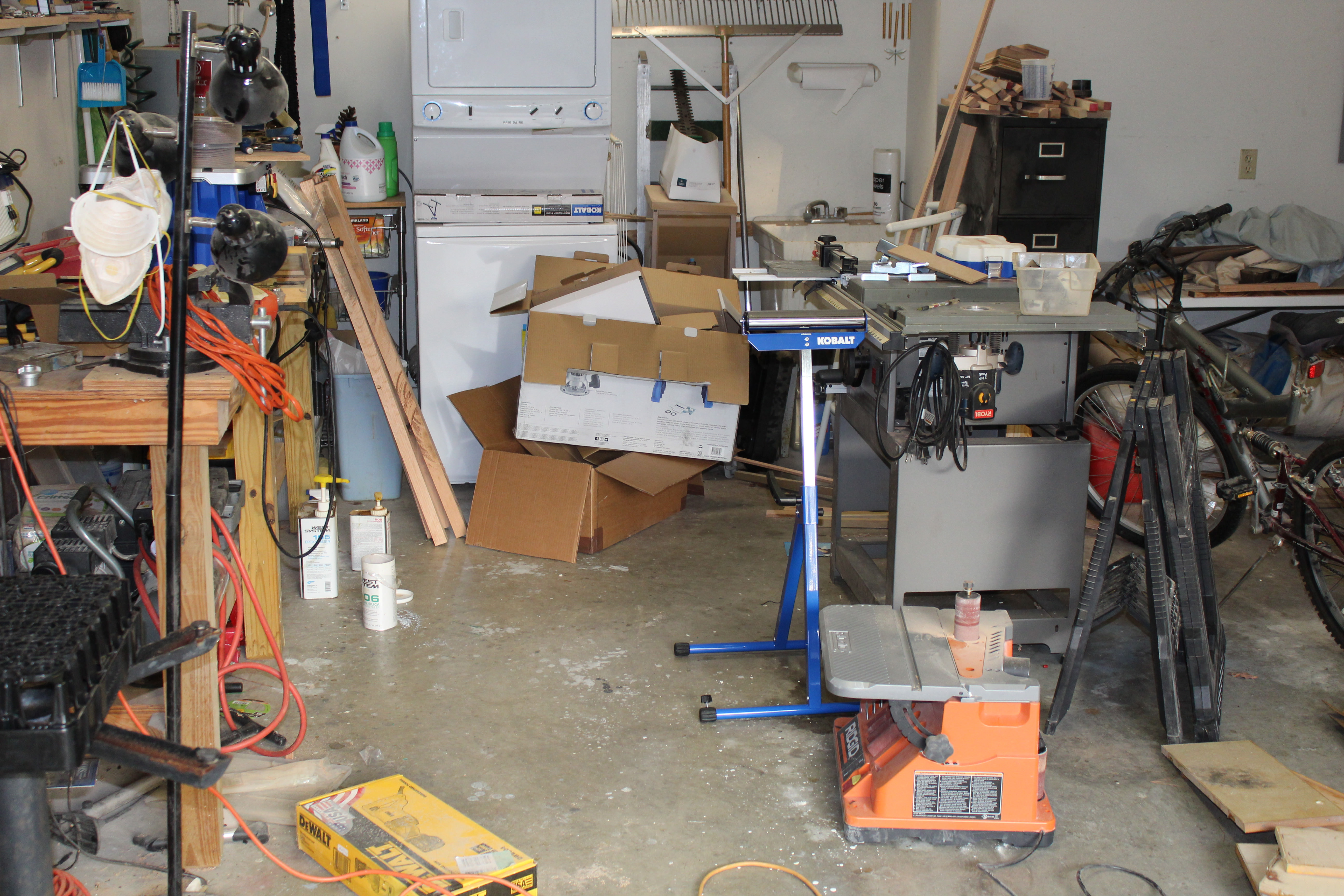

Next up while waiting for the epoxy to dry was to do something with this disaster:

I swear the garage was clean when I got home! I went a little crazy and this was the result:

Next up, some cabinetry!

Cheers,

Mark

Since I had always intended to replace/re-engineer the windlass and anchoring setup, I neglected to do anything with it after raising the boat. Over time, I thought about removing it but had a nagging idea that it was probably corroded and would be hard to deal with. Not the case! First up was to remove the 4 bolts on the bottom - no problem. What next? It turns but won't separate. I never got any documentation for the windlass when I bought the boat, so the internet to the rescue!

The windlass is a Lofrans Progress 1. Obviously long out of production but I did find a site that had a manual for it. Big letdown except it had an exploded parts diagram which did the trick:

The capstan(?) initially didn't want to budge but since it was destined for the trash - out with the BFH. It budged! Next off was the gypsy, three snap rings and a few taps and then a big bang as the bottom part fell out and dropped to the floor. A little prying on the top half to break loose the sealant and it's cleanup time. After scraping and sanding I cut a plug and epoxied it in:

The weird looking thing is a freezer bag filled with thickened epoxy. Learned that trick from watching Mads on the SailLife videos. Fill the baggie with thickened epoxy, snip off the tip and squeeze. Perfect for filling gaps! As an aside, I highly recommend watching SailLife on Youtube. The guy's name is Mads, lives in Denmark and is doing an extensive refit on a Warrior 38. Good stuff!

Next up while waiting for the epoxy to dry was to do something with this disaster:

I swear the garage was clean when I got home! I went a little crazy and this was the result:

Next up, some cabinetry!

Cheers,

Mark

Last edited:

Measure once, Cut twice! (Part 1):

Whilst continuing the deck repairs after removing the windlass I started cutting pieces for the starboard aft pantry:

The original interior layout purposed this area as a cooler, complete with the fiberglass tub surrounded by spray-in foam for insulation. This had been unused by the PO and filled with various bits & pieces. I originally placed the a/c unit in there but eventually decided to try to utilize the space better. Out came the cooler, foam, and a bunch of trapped water and mold! I (rant on) seriously hope that these foam products have improved over the years because everywhere I found foam I also found trapped water and mold. What were they thinking? (rant off). I ripped all that out, added shelves and doors and had a nice deep pantry for storage. Except it was a little too deep - to reach the back I could go head and shoulders in through the doors!

My thought on interior version 2.0 is that the pantry does not need to be this deep. Arm length deep is fine, so I measured my arm and eyeballed where the cabinet face should be. Problem is, now the old cabinet face is no longer usable as a pattern. So, cut, trim, fit, remove. Cut, trim, fit, remove. Repeat for an hour or so, vacuum up the growing pile of sawdust at your feet a few times and eventually - it fits! Then repeat for the bulkhead. I eventually got to this point:

and gave up for the day and took the Corvette for a spin! Next morning I was back hard at it, finished trimming the bulkhead and it all fits:

Next up, part 2 of Measure once, cut twice!

Cheers,

Mark

Whilst continuing the deck repairs after removing the windlass I started cutting pieces for the starboard aft pantry:

The original interior layout purposed this area as a cooler, complete with the fiberglass tub surrounded by spray-in foam for insulation. This had been unused by the PO and filled with various bits & pieces. I originally placed the a/c unit in there but eventually decided to try to utilize the space better. Out came the cooler, foam, and a bunch of trapped water and mold! I (rant on) seriously hope that these foam products have improved over the years because everywhere I found foam I also found trapped water and mold. What were they thinking? (rant off). I ripped all that out, added shelves and doors and had a nice deep pantry for storage. Except it was a little too deep - to reach the back I could go head and shoulders in through the doors!

My thought on interior version 2.0 is that the pantry does not need to be this deep. Arm length deep is fine, so I measured my arm and eyeballed where the cabinet face should be. Problem is, now the old cabinet face is no longer usable as a pattern. So, cut, trim, fit, remove. Cut, trim, fit, remove. Repeat for an hour or so, vacuum up the growing pile of sawdust at your feet a few times and eventually - it fits! Then repeat for the bulkhead. I eventually got to this point:

and gave up for the day and took the Corvette for a spin! Next morning I was back hard at it, finished trimming the bulkhead and it all fits:

Next up, part 2 of Measure once, cut twice!

Cheers,

Mark

Measure once, cut twice! Part 2:

After getting the pantry face and bulkhead to fit and squared up (boat square, naturally!), next was to fab up the bottom shelf. The area the shelf needs to cover is, of course, all sorts of weird angles, undercuts and so forth and I wanted it to fit well so I measured out the rough piece. And to not waste too much wood, I double-checked the measurement between both bulkheads. Just to be sure. Then I remembered I needed to adjust for the thickness of the bulkhead. I think you guys might be able to guess where this is going:

This piece took a few hours to cut & fit - the fitment against the forward bulkhead where the transverse rib meets was really tough and I had to remove both the cabinet face and bulkhead to get access, occasionally test fitting. Except I didn't test fit the aft bulkhead until I had completed the shelf!

In my defense - ok, this is just an excuse - oh, hell, no excuse. The good news, I now had a pattern available to make a new, better fitting piece. Which fit much better!

On a side note, I have an extra custom fabbed cabinet shelf designed for a custom interior cabinet, free to a good home. Any takers?

Cheers,

Mark

After getting the pantry face and bulkhead to fit and squared up (boat square, naturally!), next was to fab up the bottom shelf. The area the shelf needs to cover is, of course, all sorts of weird angles, undercuts and so forth and I wanted it to fit well so I measured out the rough piece. And to not waste too much wood, I double-checked the measurement between both bulkheads. Just to be sure. Then I remembered I needed to adjust for the thickness of the bulkhead. I think you guys might be able to guess where this is going:

This piece took a few hours to cut & fit - the fitment against the forward bulkhead where the transverse rib meets was really tough and I had to remove both the cabinet face and bulkhead to get access, occasionally test fitting. Except I didn't test fit the aft bulkhead until I had completed the shelf!

In my defense - ok, this is just an excuse - oh, hell, no excuse. The good news, I now had a pattern available to make a new, better fitting piece. Which fit much better!

On a side note, I have an extra custom fabbed cabinet shelf designed for a custom interior cabinet, free to a good home. Any takers?

Cheers,

Mark

Expensive with an added bonus: A boat interior is mostly a collection of really oddly shaped pieces, none of which are alike!At least cabinet-grade plywood is expensive!

Things start looking up:

With the shelf debacle sorted out, the pantry goes in for a final test-fit:

I had to rough cut some openings to be able to access the mounting screws but I'm still working on just what I want the various door and drawer interface with the cabinets to look like. I'll be better able to explain this next time home but I'm mulling over whether to flush mount the doors into the cabinets or surface mount them. Surface mounting is much easier but does complicate the latching methods. Flush mounting takes a lot more effort to get right but I think it looks better and makes hinging and latching easier. I do know that I will not be using the push-button latches - the one time I tried that the end result was most of my stuff ending up on the cabin sole after the the first tack! I have been researching latches for the drawers and cabinets and surprisingly, so far the option I like best comes from the aviation (airline) industry. Still looking but I've got some time before I have to commit.

So, next up, using the old cabinet piece as a pattern:

The rear bulkhead for the hanging locker. Hey, it fits! First time! And then the replacement cabinet face for the hanging locker:

A little trimming and a perfect fit. Now to add the top:

Time for a beer!

Cheers,

Mark

With the shelf debacle sorted out, the pantry goes in for a final test-fit:

I had to rough cut some openings to be able to access the mounting screws but I'm still working on just what I want the various door and drawer interface with the cabinets to look like. I'll be better able to explain this next time home but I'm mulling over whether to flush mount the doors into the cabinets or surface mount them. Surface mounting is much easier but does complicate the latching methods. Flush mounting takes a lot more effort to get right but I think it looks better and makes hinging and latching easier. I do know that I will not be using the push-button latches - the one time I tried that the end result was most of my stuff ending up on the cabin sole after the the first tack! I have been researching latches for the drawers and cabinets and surprisingly, so far the option I like best comes from the aviation (airline) industry. Still looking but I've got some time before I have to commit.

So, next up, using the old cabinet piece as a pattern:

The rear bulkhead for the hanging locker. Hey, it fits! First time! And then the replacement cabinet face for the hanging locker:

A little trimming and a perfect fit. Now to add the top:

Time for a beer!

Cheers,

Mark