............... and in reference to ABYC H-27 27.6.1

27.6.1 A seacock shall be securely mounted so that the assembly will withstand a 500 pound (227 Kg) "static force applied for 30 seconds" to the inboard end of the assembly, without the assembly failing to stop the ingress of water.

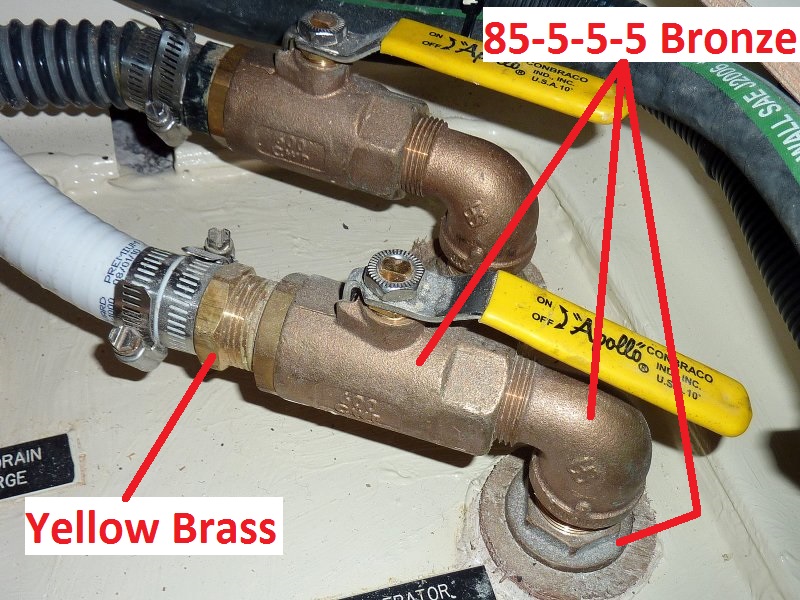

we are dealing with a

static load, not a shock load as you have described. Remember this is bronze, a brittle material, so very little plastic deformation, no work hardening, no warning, just SNAP.

The static load test is to ensure that human beings, gear, loose tankage, a scuba tank etc. could land on a seacock and it should hold. The idea is that this static test is above what the expected load whether shock or gradual may be on a thru-hull. All one can do is test to see if the available products out there meet the existing minimum standards, which I did..

The load I applied was done gradually, just as the industry does when testing to this standard. I consulted with both Groco and ABYC before doing it to make sure it was done as close to what they suggest/do as possible. It is very difficult to get to a "static load" of 500 pounds without shock loading the fitting if you don't apply it gradually. I cranked the winch gradually just as Groco does it.

This 500 pounds for 30 seconds is what the ABYC landed on as a test for seacocks meeting the minimum safety standard. Brian at ABYC is looking into the origins of it for me but it takes time to go through all the PTC data. All I know now, from the ABYC is that extensive testing was done to come to that test figure. I did not create the test and can't change it. The ABYC standard is also voluntary, so if you're comfortable with an in-line valve then keep it. According to ABYC builders building to NMMA standards are supposed be building their vessels to have 100% compliance in H-27, among other standards.

In speaking with Groco my findings are right in-line with their own in-house H-27 test findings. This is to say that in-line valves threaded to a thru-hull, in multiple sizes, do not meet ABYC H-27 standards. They were finding a 3/4" thru-hull failing in the mid to low 300's. I was an 1 3/8" below top hard piping and hit 404 pounds but this was with a Conbraco thru-hull not a Groco. Could have been less with a Groco but I have not yet tested one.

Groco tech support/engineering suggests using an in-line valve on a thru-hull only for above waterline use. They used to state this in their catalog but a big customer got "upset" so they removed the big red circle with the red line through it, placed over an in-line valve on a thru-hull.

It becomes frustrating to me to go to boat shows and see brand new boats built to NMMA standards, which includes compliance in ABYC H-27, with these installations. Many of these boats are being sold for 200k +/- with below waterline fittings that simply do not meet the minimum standards, when they are sold and labeled as NMMA / ABYC etc. etc...

And yes, the concern here is as you stated, "just SNAP

" but I guess it could also be "Carpe Diem" when buying a new 6 figure vessel.......