Ever since we have owned Smitty there has been a pesky leak in the hatch right over our berth. It wasn’t constant but it would drip a lot anytime it rained.

The previous owner tried to fix this with lots of crappy silicone caulking around the metal frame of the hatch. The problem is that one, you should almost never use silicone on boats and two, it wasn’t the frame of the window that was the source of the leak. So on top of having crappy silicone caulking to cleanup I still had to fix the leak.

After a little bit of research and testing I found out that leak was actually coming from the friction hinges. These hinges are sealed with gaskets at the factory and those gaskets do breakdown and need to be replaced. With the shrink wrap up this winter it was a perfect time to take care of this nuisance.

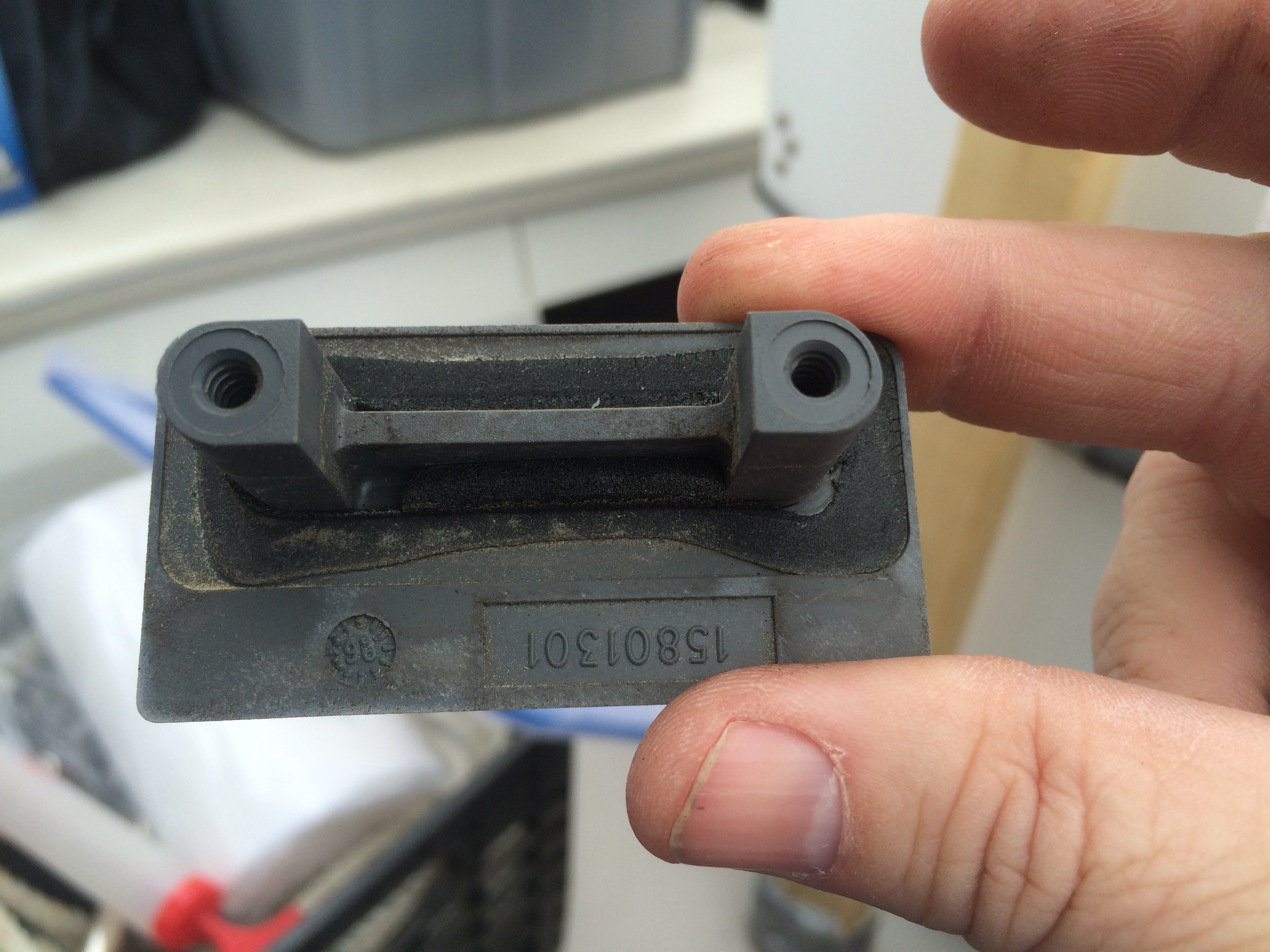

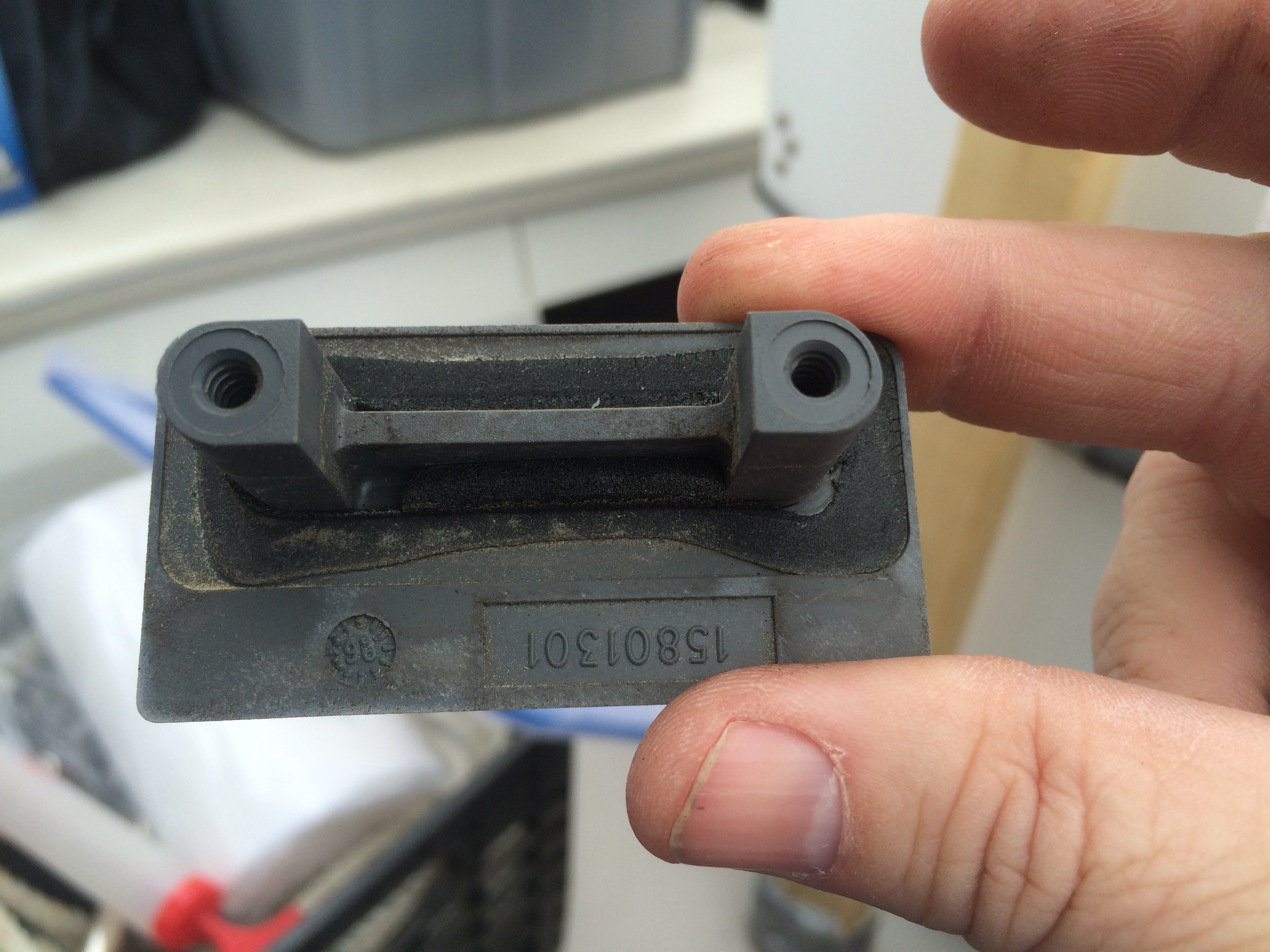

When I removed the hinges it was easy to see that the foam gasket had deteriorated to almost nothing.

To fix this I could have ordered new foam gaskets from Lewmar. But I felt that a better repair was possible. I went to my boat guru, RC from Compass Marine (aka Maine Sail). I had previously learned of the wonders of butyl tape from him for bedding hardware. I felt that butyl tape would make a longer lasting fix for the hinges. After a quick confirmation with RC that the plastic could handle the butyl tape if I took time to tighten the screws, I decided to use butyl tape for the repair. I had previously purchased a couple of rolls Bed-It Butyl Tape from Compass Marine, so I was all set to do the repair.

I removed the old gasket and then cleaned the inside of the plastic hinge connector with soap and water. I then let the connector dry completely for a couple of days. This job was made easier by having the shrink wrap up so I didn’t have to worry about more leaks during the repair. I worked the butyl tape to make a layer of the material on the inside of the plastic hinge connector.

The hinges were then reassembled. I didn’t tighten the screws too tight. Just enough to start to compress the butyl tape. I then let it sit; it was about 65 degrees under the clear shrink wrap on this cold, sunny day due to the greenhouse effect. Later in the day I turned the screws a couple more turns to compress the butyl tape a little more. Over the next couple of weeks, whenever the temperature got above 65 degrees under the shrink wrap I would give the screws a couple of turns. Eventually it was completely tight and the excess butyl tape had squished out from under the hinge connector.

I used RC’s technique to cleanup the excess butyl tape. I used a ball of excess butyl tape from another project and pulled away the butyl tape from the hatch. I then did a quick wipe with a clean rag with a little mineral spirits.

While I was there I also replaced the O-rings and lubricated the hatch dogs. I used the Lewmar Drip Stop Hatch Dog Rebuild Kit from Catalina Direct.

The hatch dogs weren’t leaking yet but I figured a little preventative maintenance is always a good thing.

The shrink wrap has been off for a little over 2 months now and no sign of any leaks.

Cross posted on my blog.

The previous owner tried to fix this with lots of crappy silicone caulking around the metal frame of the hatch. The problem is that one, you should almost never use silicone on boats and two, it wasn’t the frame of the window that was the source of the leak. So on top of having crappy silicone caulking to cleanup I still had to fix the leak.

After a little bit of research and testing I found out that leak was actually coming from the friction hinges. These hinges are sealed with gaskets at the factory and those gaskets do breakdown and need to be replaced. With the shrink wrap up this winter it was a perfect time to take care of this nuisance.

When I removed the hinges it was easy to see that the foam gasket had deteriorated to almost nothing.

To fix this I could have ordered new foam gaskets from Lewmar. But I felt that a better repair was possible. I went to my boat guru, RC from Compass Marine (aka Maine Sail). I had previously learned of the wonders of butyl tape from him for bedding hardware. I felt that butyl tape would make a longer lasting fix for the hinges. After a quick confirmation with RC that the plastic could handle the butyl tape if I took time to tighten the screws, I decided to use butyl tape for the repair. I had previously purchased a couple of rolls Bed-It Butyl Tape from Compass Marine, so I was all set to do the repair.

I removed the old gasket and then cleaned the inside of the plastic hinge connector with soap and water. I then let the connector dry completely for a couple of days. This job was made easier by having the shrink wrap up so I didn’t have to worry about more leaks during the repair. I worked the butyl tape to make a layer of the material on the inside of the plastic hinge connector.

The hinges were then reassembled. I didn’t tighten the screws too tight. Just enough to start to compress the butyl tape. I then let it sit; it was about 65 degrees under the clear shrink wrap on this cold, sunny day due to the greenhouse effect. Later in the day I turned the screws a couple more turns to compress the butyl tape a little more. Over the next couple of weeks, whenever the temperature got above 65 degrees under the shrink wrap I would give the screws a couple of turns. Eventually it was completely tight and the excess butyl tape had squished out from under the hinge connector.

I used RC’s technique to cleanup the excess butyl tape. I used a ball of excess butyl tape from another project and pulled away the butyl tape from the hatch. I then did a quick wipe with a clean rag with a little mineral spirits.

While I was there I also replaced the O-rings and lubricated the hatch dogs. I used the Lewmar Drip Stop Hatch Dog Rebuild Kit from Catalina Direct.

The hatch dogs weren’t leaking yet but I figured a little preventative maintenance is always a good thing.

The shrink wrap has been off for a little over 2 months now and no sign of any leaks.

Cross posted on my blog.