As on mine, which as an Autohelm unit. Those wheels, "bogies," as I refer to them, are mounted on cast plastic bosses. These can break off. I "upgraded" my pilot by drilling them and inserting small, metric, flat-head screws with locking nuts. The flat heads were outside, and the plastic countersunk for them.On my older version, there are 6 or so “wheels” inside that support the ring and allow it to move pretty easily. I don’t know if they changed that in later models.

Raymarine ST4000+ Auto Pilot clutch pop out

- Thread starter Growl

- Start date

I repaired mine because the clutch would not disengage and would make a chattering noise.

The the tiny roll pin in the lever handle sheared off they are hard to find I found them at Granger and Napa it's a 1/8"

roll pin

I have yet to actually use the autopilot to stay a course but, if you get near (the flux Compass or whatever they call it) with your cell phone it can take you go way off course! on my other boat I actually would steer my b with the magnetic field from my cell phone just by holding it near the control unit

The the tiny roll pin in the lever handle sheared off they are hard to find I found them at Granger and Napa it's a 1/8"

roll pin

I have yet to actually use the autopilot to stay a course but, if you get near (the flux Compass or whatever they call it) with your cell phone it can take you go way off course! on my other boat I actually would steer my b with the magnetic field from my cell phone just by holding it near the control unit

Last edited:

That sounds about right to me.I could actually adjust the tension knob now that I had it off the wheel. I guess rinse out with soapy water and mount to wheel?

Greg

jssailem

SBO Weather and Forecasting Forum Jim & John

- Oct 22, 2014

- 23,804

Growl. It is difficult to give directions when i feel like walking through a mine field. Or suggestion of surgery with the doctor blind folded.

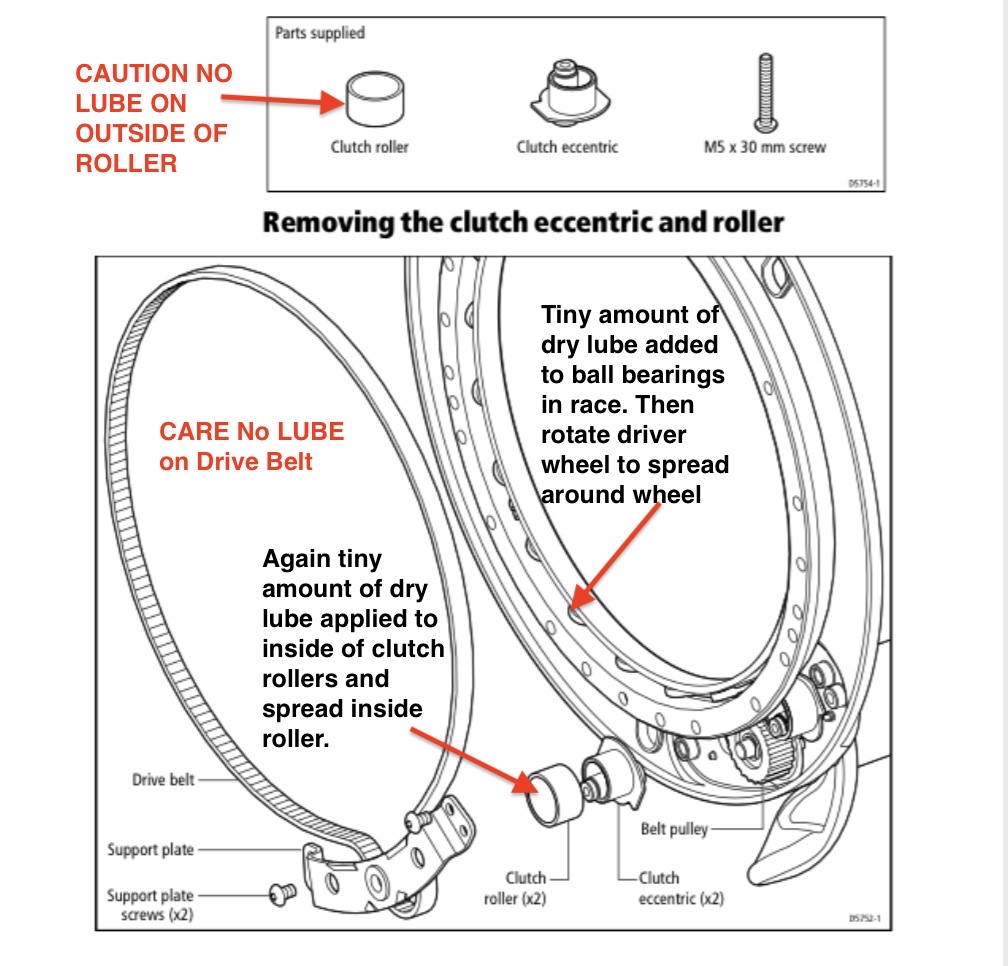

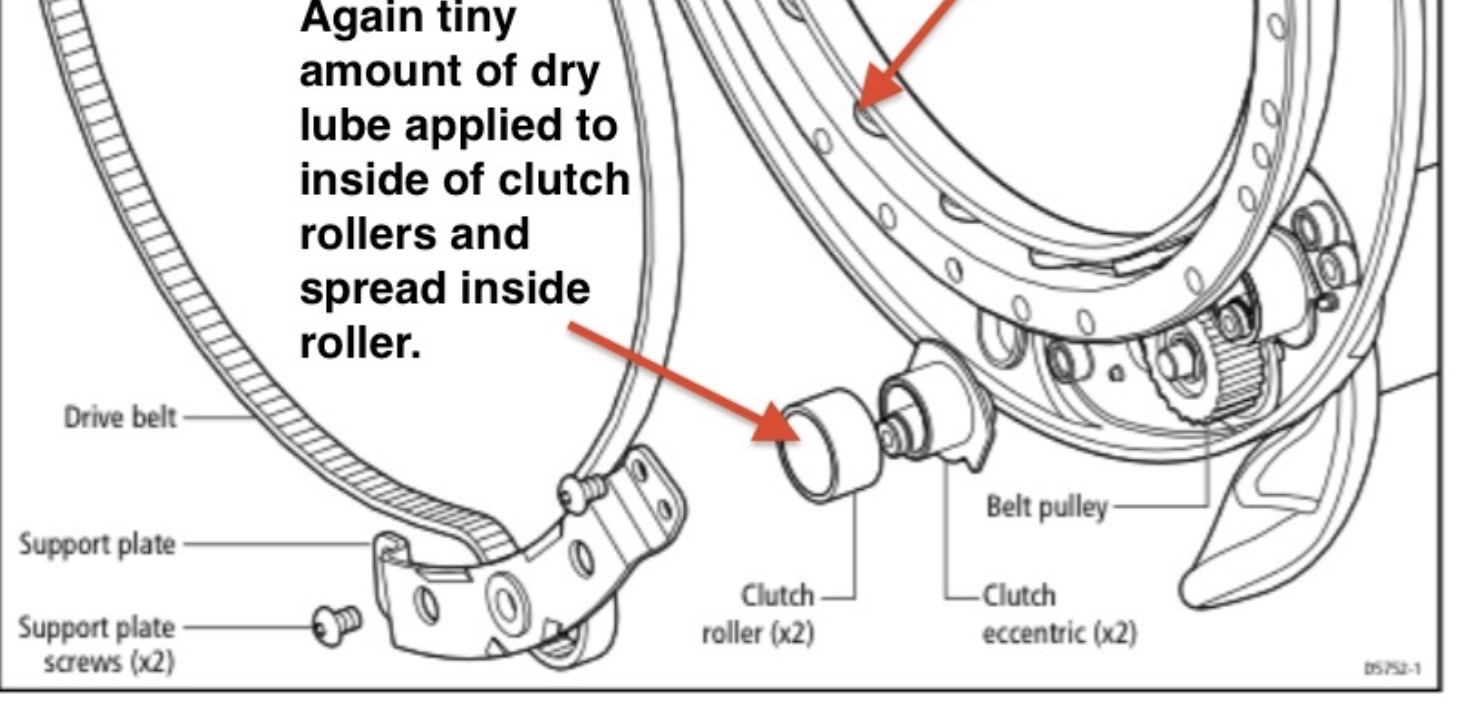

Only skimpiest amount of dry lube to the places indicated. Like waving the drop near the unit but not touching it. Follow the red letter caution. No lube on the drive belt.

The image of breaks in the drive wheel. These caused the drive wheel to slip snd jump. They showed up as chatter and this caused the clutch to pop. Be sure you have all the ball bear in place. Each one fills one of the spots on the drive wheel.

Take care in tightening the screws. You want the snug but not over tightened.

Only skimpiest amount of dry lube to the places indicated. Like waving the drop near the unit but not touching it. Follow the red letter caution. No lube on the drive belt.

The image of breaks in the drive wheel. These caused the drive wheel to slip snd jump. They showed up as chatter and this caused the clutch to pop. Be sure you have all the ball bear in place. Each one fills one of the spots on the drive wheel.

Take care in tightening the screws. You want the snug but not over tightened.

Should I take this apart or leave it be everything appears to be fine. I’m hoping the tensioner just needed adjustment.

Attachments

-

343.6 KB Views: 120

jssailem

SBO Weather and Forecasting Forum Jim & John

- Oct 22, 2014

- 23,804

I was the investigative type, so I did take mine apart.

That is how I cleaned out the small amount of accumulated dirt/dust/sea salt beneath the metal plate. It is also how I got to the "eccentrics" to add the "TINY" (not more than a smear using my little finger) of dry lube to the INSIDE of the clutch rollers. This allowed me to more easily adjust the clutch tension after I reassembled the wheel. The clutch rollers apply the pressure to the belt. The Eccentrics rotate inside the clutch roller and provide the adjustable force against the clutch roller. The TINY (just a hint) amount of lube inside the clutch roller allows the roller to rotate over the outer side of the eccentric. The roller rotates against the belt and no lube should be between the belt and the clutch roller or on the belt.

That is how I cleaned out the small amount of accumulated dirt/dust/sea salt beneath the metal plate. It is also how I got to the "eccentrics" to add the "TINY" (not more than a smear using my little finger) of dry lube to the INSIDE of the clutch rollers. This allowed me to more easily adjust the clutch tension after I reassembled the wheel. The clutch rollers apply the pressure to the belt. The Eccentrics rotate inside the clutch roller and provide the adjustable force against the clutch roller. The TINY (just a hint) amount of lube inside the clutch roller allows the roller to rotate over the outer side of the eccentric. The roller rotates against the belt and no lube should be between the belt and the clutch roller or on the belt.

jssailem

SBO Weather and Forecasting Forum Jim & John

- Oct 22, 2014

- 23,804

Go to a marine store and get a can of "SailKote"

Very usable and will not harm the plastic in my experience.

Very usable and will not harm the plastic in my experience.

Luckily I have some gift cards!

Attachments

-

660.8 KB Views: 106

jssailem

SBO Weather and Forecasting Forum Jim & John

- Oct 22, 2014

- 23,804

Good image of wheel.

I did not see any cracks in the plastic wheel. You have come corrosion going on with a few of the metal inserts designed by AutoHelm to receive screws from Helm Wheels with differing spoke patterns.

I would treat all of those with a product called Corrosion Block. It can be found at West Marine or many other places. I prefer the no pressure spray container (I purchased mine from the manufacturer Lear Chemical -https://www.learchem.com/products/corrosion-block.html). A small squirt on a Q-Tip, then rubbed on the metal insert will clean the corrosion and provide a layer of protection.

I found this stuff to be exceptional I sprayed a little on a cheap master lock and left it out in the marine environment 24/7. 18 months later fully functional and just starting to show a touch of corrosion. Time for another application.

I did not see any cracks in the plastic wheel. You have come corrosion going on with a few of the metal inserts designed by AutoHelm to receive screws from Helm Wheels with differing spoke patterns.

I would treat all of those with a product called Corrosion Block. It can be found at West Marine or many other places. I prefer the no pressure spray container (I purchased mine from the manufacturer Lear Chemical -https://www.learchem.com/products/corrosion-block.html). A small squirt on a Q-Tip, then rubbed on the metal insert will clean the corrosion and provide a layer of protection.

I found this stuff to be exceptional I sprayed a little on a cheap master lock and left it out in the marine environment 24/7. 18 months later fully functional and just starting to show a touch of corrosion. Time for another application.