Good morning. I have been having some issues with my roller reefing for some time now and am at a loss for a fix. This is the older style reefing system that has the wire sewed into the jib. There is a "claw" on the top of the system that hooks onto the fore stay. It is made of two open stainless steel U shaped pieces that you twist sideways and slip on the fore stay. The problem I have been having is that if you when you unfurl or furl the jib, the upper bearing (which is very smooth by the way) wraps around the forestay and really messes things up. I sail in some heavy weather and really need the ability to reef quickly. If there was a way to hold the bearing assembly away from the fore stay then there would not be a problem, but the two components converge at the mast head and there is just not enough room to keep the two from getting tangled. I was at the marina yesterday doing some winterizing and notice that some of the boats look like they are not using a fore stay but using the wire in the jib to support the mast. I can only see one single stay which is the furling system. This could be a more modern system designed to somehow use the jib stay to support the mast and allow furling. Does anyone have any experience in this regard? Thanks so much for any help.

Question about roller reefing

- Thread starter davidmhull

- Start date

I'm not sure how the system you are describing works but normal roller furling has a forestay inside the foil, the luff tape slides up the foil. The foil spins around the forestay and the sail furls around the forestay.

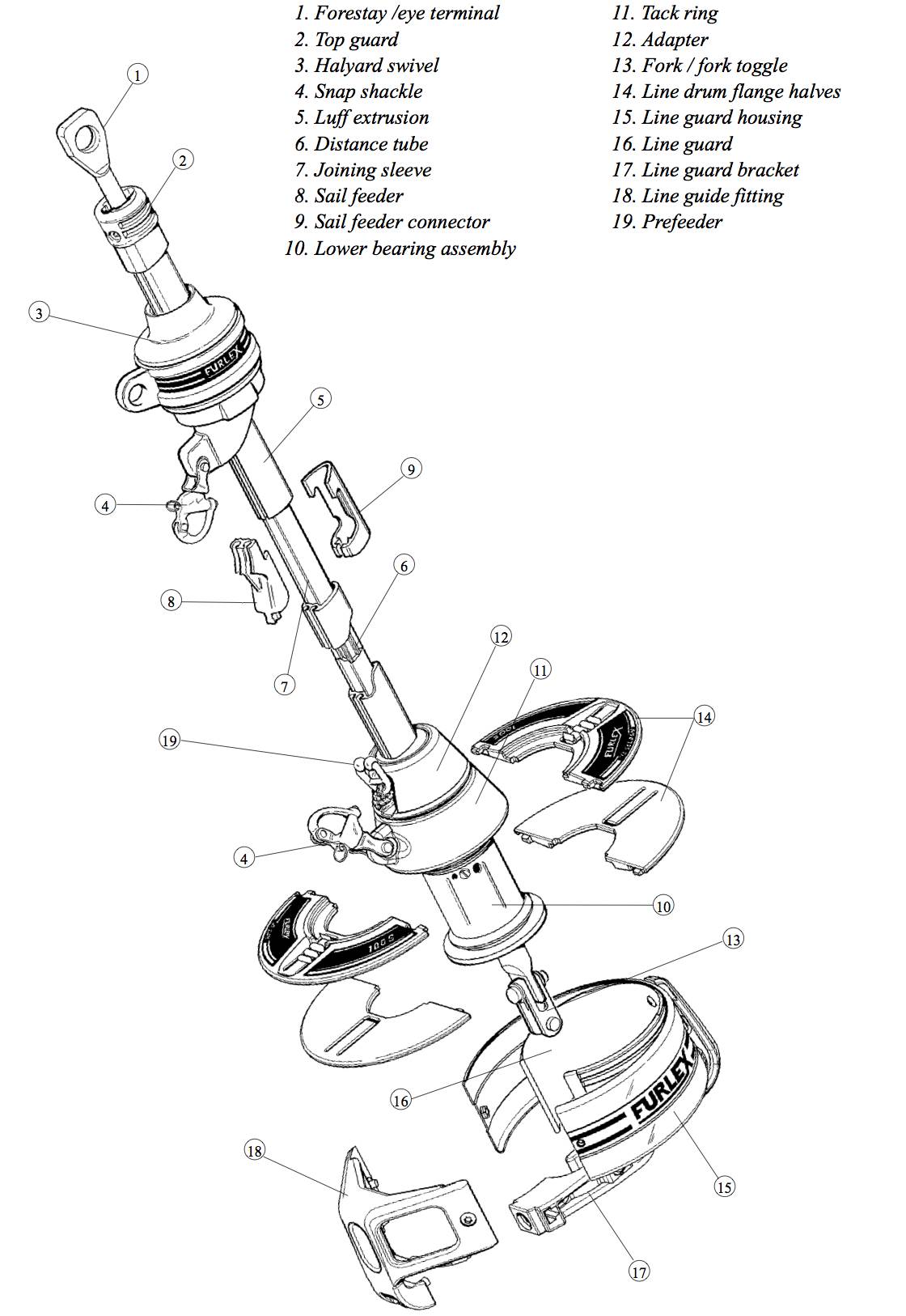

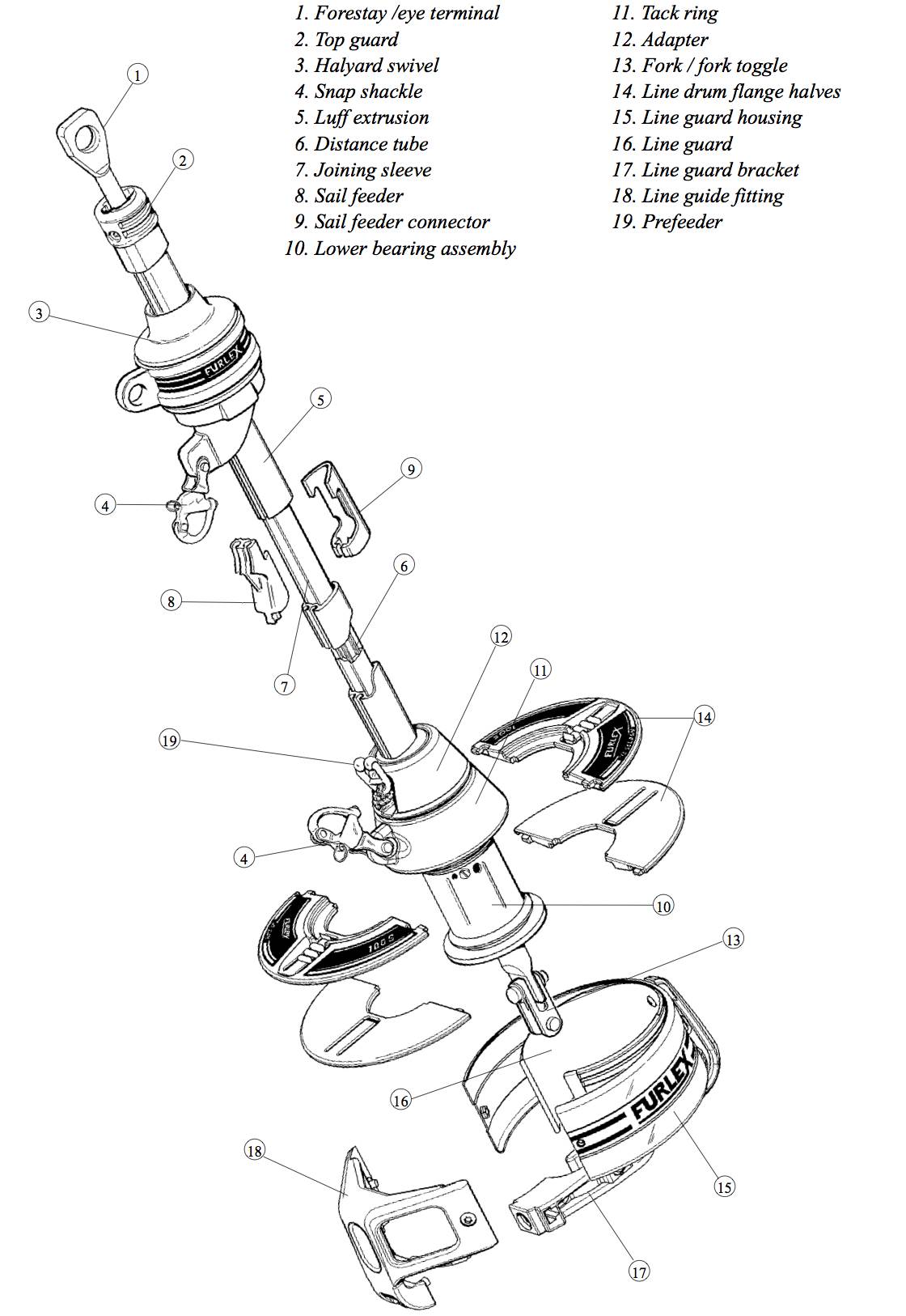

In this image, Item 1 is the top of the forestay and item 13 is the bottom.

In this image, Item 1 is the top of the forestay and item 13 is the bottom.

Thanks very much for the replies. This is a picture of the system I have. I know it is a bit outdated but it has advantages I appreciate. I can install my genoa which also has a wire luff in minutes. The problem I am having is that the "bail" that hooks to the fore stay sometimes wraps around it. There is very little clearance at the top of the mast for the jib halyard and the fore stay. They converge too close to keep the upper bearing assembly from wrapping. It's kind of like what people describe as halyard wrap but somewhat different as it is not the halyard that wraps around the fore stay but the entire assembly. The second picture describes a way of preventing halyard wrap and perhaps it would work in my situation. Does anyone have any experience with this? Thanks.

Attachments

-

153.4 KB Views: 236

-

221 KB Views: 383

I have never seen this type of set-up (which means little) however I can see how the top would wrap along with the sail when furling/unfurling the head sail. If there were a line pulling it towards the mast if would keep it in place, but that does not seem possible. maybe this issue is why I've never seen these before. Or maybe the system was designed for a hank on sail only and not made for furling.

Modern head sail furling systems utilize the head-stay which continues to support the mast.... No wire in the head sail. The furling system has a "foil" that surrounds the head-stay that spins independently allowing the sail to furl/unfurl.

I am assuming there is no company name on any of the components otherwise you would have search that route....

Modern head sail furling systems utilize the head-stay which continues to support the mast.... No wire in the head sail. The furling system has a "foil" that surrounds the head-stay that spins independently allowing the sail to furl/unfurl.

I am assuming there is no company name on any of the components otherwise you would have search that route....

Last edited:

NYsail, The manufacturer is Schaefer. Sorry I did not include that. Hunter 216, thanks for the idea. I have often looked up there and said to myself that if I just had some way of tethering the upper bearing then it could not wrap. The problem is that if I connect a bar to the mast then I will not have a way to raise and lower the upper bearing assembly when I want to change out sails for various wind conditions. If I put a bridle around the mast and hoist it with the jib halyard then I would not be able to raise and lower the mainsail. I agree that the best way to fix this would be to somehow secure the upper bearing to the masthead or mast but I just can't figure out how to do it. Thanks again.

Suggest looking at the top furling drum is properly turning because if not, it will need maintenance

I have seen a V attachment on the top bearing that cradles the mast when raised and prevents halyard wrap. This would be very similar to what @Hunter216 is suggesting. It should work for this setup and could be clamped around the bearing or welded on the opposite side of the hooks.

My furler would get wrapped in halyards all the time causing some Oh S*** reefing moments when you least need them. My solution was to tension the halyards very tight to the mast avoiding the contact. Has worked well all last season. Always put the unused halyards on the winch to make sure the tension was still good before setting out. I'm a day sailor so every sail is an individual event with all the preps done before shoving off for the day.

Does the swivel go within a 2 or 3 inches of the top of the forestay? If the swivel is well below the top, it will be more likely to cause wrapping.

Do you have an adjustable backstay?

Suggestions:

Let's see a picture with the sail hoisted all the way up to the max, please, so we can see the actual geometry up there.

Judy Blumhorst

Distributor for Selden, Harken, Schaefer, Profurl

PS Are you in Richmond CA? If so, I'd be happy to meet you in Alameda to take a look at your furler problem. No charge.

Do you have an adjustable backstay?

Suggestions:

- Get rid of the extra halyard shackle. Use the D-shackle that came with the top swivel or one of similar length.

- If the head of the sail doesn't allow the upper swivel to get within an 2-3 inches of the top, put a pendant between the head of the sail and the upper swivel. That will get the upper swivel where it should be: up high.

- Use moderate tension on the halyard, but not enough to cause the forestay to go slack. Otherwise the halyard will be holding the mast up, and the exit box isn't engineered to do that.

- If you have an adjustable backstay, tension it moderately before furling to reduce halyard and forestay sag

Let's see a picture with the sail hoisted all the way up to the max, please, so we can see the actual geometry up there.

Judy Blumhorst

Distributor for Selden, Harken, Schaefer, Profurl

PS Are you in Richmond CA? If so, I'd be happy to meet you in Alameda to take a look at your furler problem. No charge.

That’s a wonderful offer from Dr Judy.My thinking is you attach a short piece of material to the actual bearing. When you hoist the sail to the top where it is close to the mast it is long enough to touch the mast. If it rotates the bar would prevent it.

I finally found the picture of what I was suggesting. Comes from the CDI furler manual attached.

Attachments

-

515 KB Views: 180

Last edited:

Yes crazy Dave it is very smooth. I mentioned that in my original post because that would obviously cause this problem. Thanks. No Judy I am in Richmond VA. I do a lot of my sailing in the Chesapeake bay and down to the outer banks. I am moored at a place called Lewisetta not far from Tappahannock. You are welcome to come and visit. I'm sorry I can't send an actual picture right now since I am two hours from the marina. Mine doesn't have the extra shackle. That is a stock photo I found. My upper bearing goes all the way to the top. I think that is one of the problems. The jib stay and the halyard converge at the masthead and that's where the problem is. I can't shorten the wire luff however so I am pretty much stuck with that geometry. I really like the idea of a V shaped thingy that would hit the mast when furling or unfurling and keep the upper bearing from wrapping around the fore stay.

The second picture in your original post shows the solution. Most furler recommend a minimum angle between the halyard and the forest a of 15°(I think). The guide is mounted on the mast to provide the proper angle for the halyard.

You are correct Hydro Therapy. A lot depends on the tension on the jib. The problem is that it is not dependable. If you ever get a chance to sail the Chesapeake bay you will find that the wind can go from 10 to 50 knots in a heartbeat with all the summer squalls. My first sailboat was a 40' Chesapeake dead rise that was gaff rigged. When the wind kicked up you could perform what was called a Coopertown reef. You drop the gaff boom and you half the sail area in about one minute or less. Very handy. I still got dismasted out by the wolf trap light house but that's another story. I sailed that boat for 30 years. Not being able to reduce sail can be serious and I need to make this rig bullet proof. Thanks very much for all the replies.