Note: This post turns out to be based on erroneous information (MaineSail does it again). The original thru hulls in my boat are evidently not NPT. Worth reading though for a full discussion of the issue. You won't have the same experience I did if you buy new through hulls off the rack at the typical marine store.

(Begin original post)

First let me say that I don't recommend doing this. It especially should not be done if there is any chance of the through hull or attached pipe or hose turning into a hand or foot hold or having something heavy fall on it. In view of the large number of boats that have Groco or similar ball valves threaded on to through hull fittings, some perspective is probably in order because there are lots of things that can be improved and you sometimes have to prioritize.

My boat came with gate valves which should definitely be replaced yesterday if you have them. That was when I first learned about the thread mismatch issue. I even put a piece on my blog about the expensive (I thought it was expensive at the time but I hadn't yet heard the term "boat buck") pickle I was in. I even made up a nice little CAD drawing showing why the thread mismatch is so horrible.

The yard manager, who was a very knowledgeable guy, told me that they had been doing it for 20 years and he had never heard of a problem. I took a pair of NPT and NPS fittings, screwed them together hard, and knocked on them a bit. They felt solid. So, I did as the yard manager suggested and ended up with four on my boat. Two are a few inches above the waterline and small so I’m not too concerned about them. Another is in a very protected space and, like the previous two, is only half inch. Groco doesn’t make seacocks that small.

The fourth one however, is inch and a half. That one could easily overwhelm the boat before I could get it plugged. I decided to put a proper Groco adapter on it. This also gave me a chance to assess the condition of the mismatched threads.

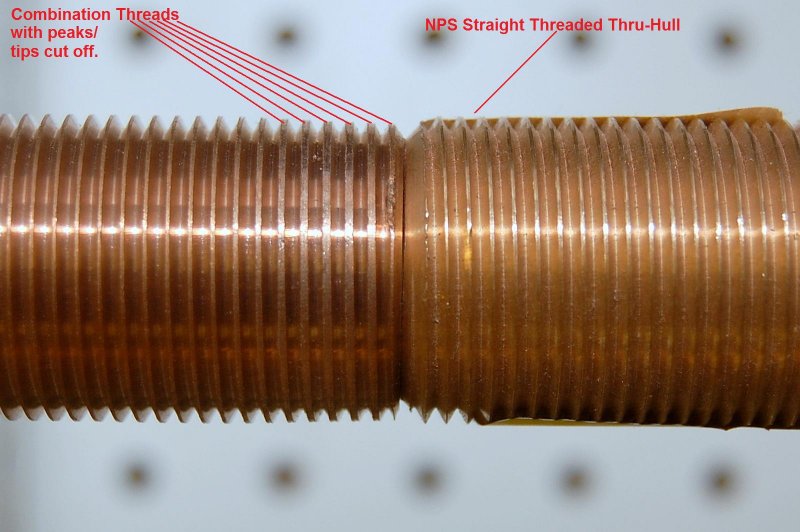

The valve was quite hard to take off. I could just barely move it with a pipe wrench in the confined space. I had only used Teflon tape on the threads but it still needed the wrench for most of the removal. The threads can be seen below. There appears to have been pretty good engagement and contact and no sign of thread distortion. The Groco adapter turned easily onto the through hull after the threads were cleaned up.

I don’t think the thread mismatch is as much of an issue in these installations as the lack of a flange and having the valve often way up at the full length of the through hull where there is a lot of leverage and only the small nut area to support it. If I’d seen the condition of these threads before I was committed to the project, I might not have been so quick to do it myself although I would, of course, recommend that anyone else do it.

It will be nice to have the valve easier to replace anyway. This is a holding tank pump out line and, as you can see by the third picture, the stuff really does a job on the stainless ball. The seawater side is shiny.

Here's how I'm installing the Groco adapter without removing the thru hull to cut it short:

http://www.rogerlongboats.com/09Winter.htm#January27

(Begin original post)

First let me say that I don't recommend doing this. It especially should not be done if there is any chance of the through hull or attached pipe or hose turning into a hand or foot hold or having something heavy fall on it. In view of the large number of boats that have Groco or similar ball valves threaded on to through hull fittings, some perspective is probably in order because there are lots of things that can be improved and you sometimes have to prioritize.

My boat came with gate valves which should definitely be replaced yesterday if you have them. That was when I first learned about the thread mismatch issue. I even put a piece on my blog about the expensive (I thought it was expensive at the time but I hadn't yet heard the term "boat buck") pickle I was in. I even made up a nice little CAD drawing showing why the thread mismatch is so horrible.

The yard manager, who was a very knowledgeable guy, told me that they had been doing it for 20 years and he had never heard of a problem. I took a pair of NPT and NPS fittings, screwed them together hard, and knocked on them a bit. They felt solid. So, I did as the yard manager suggested and ended up with four on my boat. Two are a few inches above the waterline and small so I’m not too concerned about them. Another is in a very protected space and, like the previous two, is only half inch. Groco doesn’t make seacocks that small.

The fourth one however, is inch and a half. That one could easily overwhelm the boat before I could get it plugged. I decided to put a proper Groco adapter on it. This also gave me a chance to assess the condition of the mismatched threads.

The valve was quite hard to take off. I could just barely move it with a pipe wrench in the confined space. I had only used Teflon tape on the threads but it still needed the wrench for most of the removal. The threads can be seen below. There appears to have been pretty good engagement and contact and no sign of thread distortion. The Groco adapter turned easily onto the through hull after the threads were cleaned up.

I don’t think the thread mismatch is as much of an issue in these installations as the lack of a flange and having the valve often way up at the full length of the through hull where there is a lot of leverage and only the small nut area to support it. If I’d seen the condition of these threads before I was committed to the project, I might not have been so quick to do it myself although I would, of course, recommend that anyone else do it.

It will be nice to have the valve easier to replace anyway. This is a holding tank pump out line and, as you can see by the third picture, the stuff really does a job on the stainless ball. The seawater side is shiny.

Here's how I'm installing the Groco adapter without removing the thru hull to cut it short:

http://www.rogerlongboats.com/09Winter.htm#January27

Attachments

-

31.1 KB Views: 701

-

55.2 KB Views: 740

-

36.7 KB Views: 692

Last edited: