Thanks for any advice or information.

Need to re-seat the big front window on a Hunter 29.5

- Thread starter Willie G

- Start date

If I recall it is a Dow product used here and will ask those to be specific as to which one. If you can get a fishing string thru the crack you can cut the caulk by pulling back and forth. Remove old caulk. NVER USE ACETONE ON THE WONDOW MATERIAL but alcohol is ok. If you cannot find a crack carefully use a putty knif to cut caulk outside and pry gently for a long distance. If squeamish get someone who has done that. Once surface is cleaned, tape off window so excess caulk will not come in contact with the rest of the boat. Remove excess caulk and smooth. Let dry. Remove tape and do final clean up.

If still concerned doing this, let or hire a

professional do this

If still concerned doing this, let or hire a

professional do this

Looks like big job and if want to replace down the road a friend

had windows leaking and just did not want to get into big job so I suggested Flex Seal and so he cleaned out as much old caulking and used masking tape and looks real good and no more leaks.

I would be worried damaging the window and I cover all my hatches and top windows on my H-36 with Sunbrella canvas covers

that snap on and can remove when not needed.

I also use Flex Seal on my RV roof works great and looks great and no dry caulking run off.

Nick

had windows leaking and just did not want to get into big job so I suggested Flex Seal and so he cleaned out as much old caulking and used masking tape and looks real good and no more leaks.

I would be worried damaging the window and I cover all my hatches and top windows on my H-36 with Sunbrella canvas covers

that snap on and can remove when not needed.

I also use Flex Seal on my RV roof works great and looks great and no dry caulking run off.

Nick

Bent windows are not cheap. There are some custom fabrication plastic factories that can make them, but quality has been hit & miss in my experience. I got a price quote for replacement windows to go on my H212 from the kind folks who host this board. Their quote was on par with direct quotes that I got from fabricators. I have not yet replaced my windows. It is on my to-do list.

Dow 795 is the glazing compound that is most often used in those types of installations. Other high end sealants recommend that you must use mechanical fasteners in addition to the sealant.

Dow 795 is the glazing compound that is most often used in those types of installations. Other high end sealants recommend that you must use mechanical fasteners in addition to the sealant.

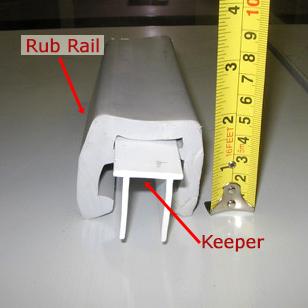

Rub rail for Hunter sailboatsAnd now a word from the sponsor...

After many years of shortage, we now offer rub rails for most Hunters from the late-90s and newer. Insert and keeper/track available.

See the product

This is VERY interesting to me. The leak on the right side of what I will call the windshield is very small and I know the area that it is coming from, but a leak none the same. I have to leave a trash bag and towel inside every time I leave the boat. Do you know if he used the Flex-steel caulk tube? Is it thick enough to not run down a 5 degree slope while it thickens / cures?Looks like big job and if want to replace down the road a friend

had windows leaking and just did not want to get into big job so I suggested Flex Seal and so he cleaned out as much old caulking and used masking tape and looks real good and no more leaks.

I would be worried damaging the window and I cover all my hatches and top windows on my H-36 with Sunbrella canvas covers

that snap on and can remove when not needed.

I also use Flex Seal on my RV roof works great and looks great and no dry caulking run off.

Nick

Is there anyone out there that has tried to patch rather than a full pull out clean and reinstall. If I were to do this I would remove and patch 12 inches either side of the leak.

I replaced mine by purchasing it through this website cost was about $650. I am really sorry I did it. The plastic lens came flat not bent to shape nor were there and screw holes drilled. It was a fairly good fit but not perfect and required sanding the edges. I used Dow to seal it and 250 lbs of salt to weight it down while it set up. If I had to do it again, I would replace the window with two opening hatches for more ventilation and fewer leaks.

We just returned from 5 days sailing. We sleep in the aft berth and it takes a strong breeze to keep it coll. Extra openings would help.

We just returned from 5 days sailing. We sleep in the aft berth and it takes a strong breeze to keep it coll. Extra openings would help.

Windows like this are usually screwed down at least until the adhesive dries. Then the screws are removed, and the holes filled with the adhesive. I imagine you could use a heat gun to bend it, but that can be risky, as plexi burns and boils easily. I have heat-formed plexi parts with the gun with plenty of success. You would need to do it off the boat.

Don’t bother. Overdrill the holes, so the plexi can expand and contract without pressing against the screws and cracking the plexi. Those grommets will not do the work. You will be screwing directly through the adhesive. It will seal.

I didn’t realize that these would come flat not pre bent. I have family that had a glass shop and said that this would about $180 including 1/2 hour to cut it out, sand the edges and prepare it for shipping. No telling how expensive shipping would be. This would be plexiglass not Lexan. Not sure if Lexan can even take to a bend though. This means that we could go to any glass shop with a template and get what we need. INTERESTING.I replaced mine by purchasing it through this website cost was about $650. I am really sorry I did it. The plastic lens came flat not bent to shape nor were there and screw holes drilled. It was a fairly good fit but not perfect and required sanding the edges. I used Dow to seal it and 250 lbs of salt to weight it down while it set up. If I had to do it again, I would replace the window with two opening hatches for more ventilation and fewer leaks.

We just returned from 5 days sailing. We sleep in the aft berth and it takes a strong breeze to keep it coll. Extra openings would help.

3/16 or 1/4” plexi or lexan will probably not be pre-bent unless 90 degree bends are needed. It will assume the shape over time. You will see. You could order this through Interstate Plastics or E-Plastics, cut it with a table saw or jig saw, bevel it with a router, drill it, glue it, and screw it down.

The fix for that particular building was solving the resonant frequency equation for the building & then suspending a calibrated weight on a spring inside the building to dampen the resonance. An egg head at MIT was the first guy to get the equation for that building figured out. I forget his name. The problem was actually caused by winds blowing at a steady speed next to the building & setting up a mechanical resonance. If you google "galloping gertie", you should find a video of the most famous example of this type of mechanical design issue.FWIW Dow was developed to hold the windows into the frames of skyscrapers. Years ago the windows were blowing out of the Handcock building in Boston (I think).