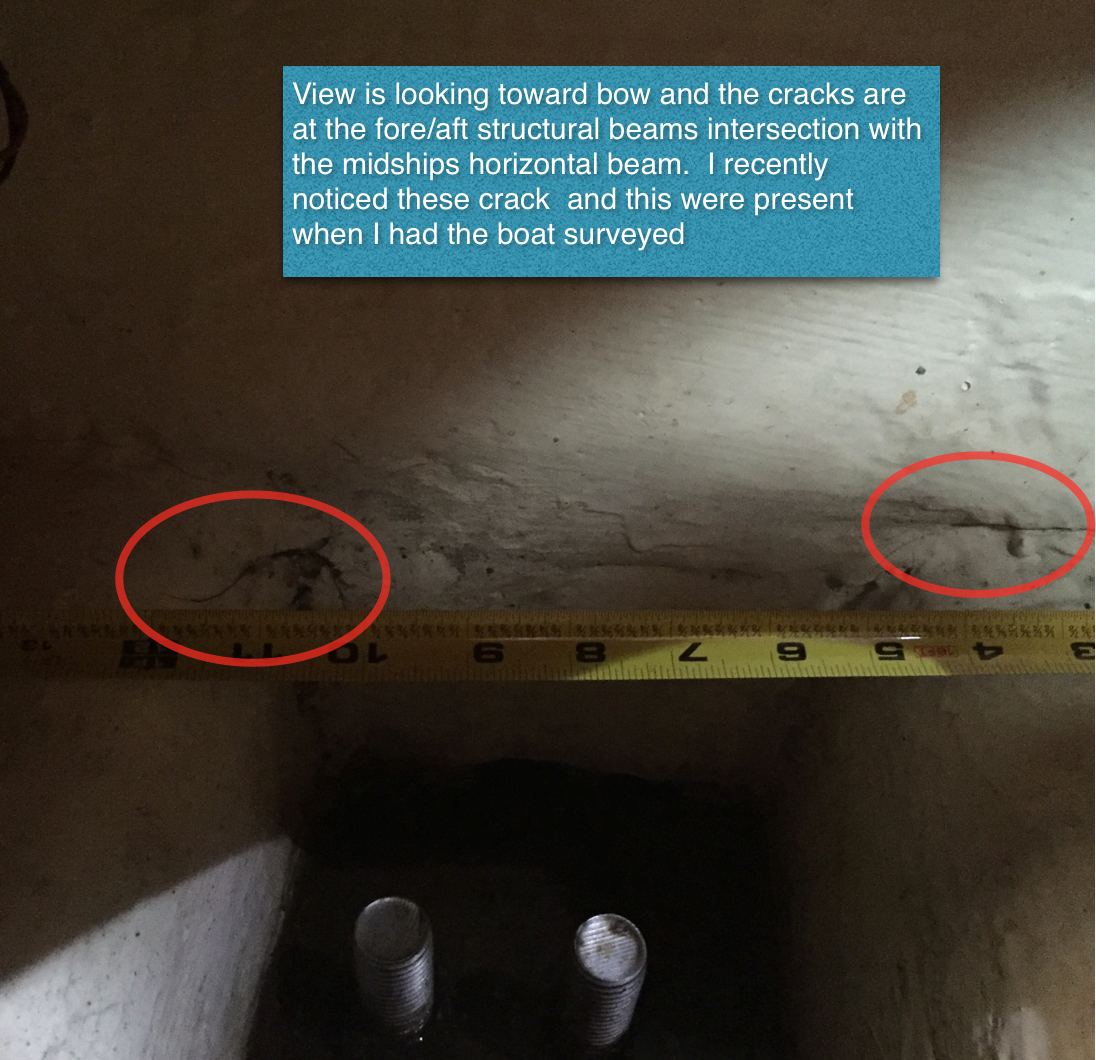

I have noticed these cracks after inspection I did following heavy seas and pounding my keel once in 4 foot sea against a shallow sand bottom. I looked at earlier pictures before the "single bang" and they are there and appear to be non-propogating.

I had my boat surveyed in Jan 2014 and there was no mention of these cracks. Since the survey, my Hunter 430 1997 has seen 10 hours of continuous 8' seas initial the delivery and I have since been anchored in 6' seas for 4 hours, and several 4'-7' seas storms. My boat just "yawned".

Are these mid ship beam cracks normal?

Suggestion of seriousness and/or repair techniques would be appreciated.

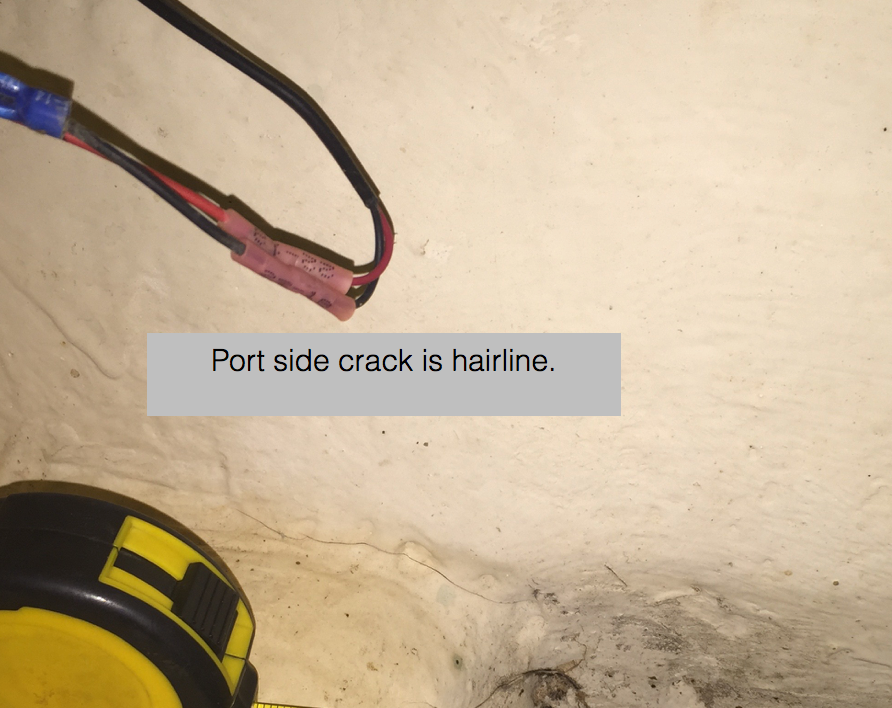

The starboard side crack in the worst and is thumb nail inserted width at the widest point.

See photos...

There no other visible cracks in the Fiberglas® structure.

Jim...

I had my boat surveyed in Jan 2014 and there was no mention of these cracks. Since the survey, my Hunter 430 1997 has seen 10 hours of continuous 8' seas initial the delivery and I have since been anchored in 6' seas for 4 hours, and several 4'-7' seas storms. My boat just "yawned".

Are these mid ship beam cracks normal?

Suggestion of seriousness and/or repair techniques would be appreciated.

The starboard side crack in the worst and is thumb nail inserted width at the widest point.

See photos...

There no other visible cracks in the Fiberglas® structure.

Jim...