Discovered this stress crack near the starboard spreader bracket. Any ideas on how to repair will be welcomed. Also wonder if this wrap around spreader bracket will work.

Hunter 1993 23.5 mast stress crack

- Thread starter kmhalvorson

- Start date

You're going to have to drop the mast and have that crack welded before you do anything else.

Wow! That’s a serious rip in the mast. It is structurally compromised. It looks dangerous to me.

It will need something more than that replacement spreader bracket. Either a large doubler or welding and retempering.

That rip is in a bad spot, really close to the groove for the slides. If it’s a Selden mast, you can email them the picture and ask for advice.

I’ve seen masts with less damage than that at the spreaders, such as indentations, dents, egged-out holes for through bolts. The local marine metal shop would fabricate two fairly large sleeves or a doubler plates of aluminum which would spread the load. Then drill and tap the sleeve or doubler to each side. Bed it with 5200. Modified the spreader bracket to fit over the reinforcement if needed. I can’t tell you how large an area or thick the plate or sleeve should be off the top of my head. The manager of the metal shop at the boat yard had 30-40 years of experience.

Good luck!

Judy

On edit: added a few more comments.

It will need something more than that replacement spreader bracket. Either a large doubler or welding and retempering.

That rip is in a bad spot, really close to the groove for the slides. If it’s a Selden mast, you can email them the picture and ask for advice.

I’ve seen masts with less damage than that at the spreaders, such as indentations, dents, egged-out holes for through bolts. The local marine metal shop would fabricate two fairly large sleeves or a doubler plates of aluminum which would spread the load. Then drill and tap the sleeve or doubler to each side. Bed it with 5200. Modified the spreader bracket to fit over the reinforcement if needed. I can’t tell you how large an area or thick the plate or sleeve should be off the top of my head. The manager of the metal shop at the boat yard had 30-40 years of experience.

Good luck!

Judy

On edit: added a few more comments.

Last edited:

Mast is easily dropped, but I wasn't sure aluminum spars can be welded.You're going to have to drop the mast and have that crack welded before you do anything else.

This mast is from ZSpars, whom I will also contact. I have seen an article on how to repair with an interior fitted sleeve, so I understand your repair description. Thanks for your response.Wow! That’s a serious rip in the mast. It is structurally compromised. It looks dangerous to me.

It will need something more than that replacement spreader bracket. Either a large doubler or welding and retempering.

That rip is in a bad spot, really close to the groove for the slides. If it’s a Selden mast, you can email them the picture and ask for advice.

I’ve seen masts with less damage than that at the spreaders, such as indentations, dents, egged-out holes for through bolts. The local marine metal shop would fabricate two fairly large sleeves or a doubler plates of aluminum which would spread the load. Then drill and tap the sleeve or doubler to each side. Bed it with 5200. Modified the spreader bracket to fit over the reinforcement if needed. I can’t tell you how large an area or thick the plate or sleeve should be off the top of my head. The manager of the metal shop at the boat yard had 30-40 years of experience.

Good luck!

Judy

On edit: added a few more comments.

Your mast is likely a 6000 series Al alloy. I'd be hesitant to weld it. It's an easy enough alloy to weld, but you can never restore the heat treated mechanical properties to the welded zones.

It looks to me like you have more damage than just that split. Looks like the spreader also pushed in the side of the mast. I would definately talk to the manufacturer of that mast.

I would have to see the mast to give an accurate opinion as to if you can put a plate on it. From what I can see, it looks like you could sleeve it or replace the mast. I'm not sure about plating. Might work.

dj

It looks to me like you have more damage than just that split. Looks like the spreader also pushed in the side of the mast. I would definately talk to the manufacturer of that mast.

I would have to see the mast to give an accurate opinion as to if you can put a plate on it. From what I can see, it looks like you could sleeve it or replace the mast. I'm not sure about plating. Might work.

dj

Yes, literally! (I see what you did there ). Got no one to blame but myself, but it still smarts.Tough break...

Thanks, DJ. I at least have the option of repair or replace the mast, the latter being much pricier. The only thing I wonder about with repair is will I feel confident with the strength of the repair? Am I going to worry about corrosion with the seams? Any idea how many years I can get out of a repair like this?Your mast is likely a 6000 series Al alloy. I'd be hesitant to weld it. It's an easy enough alloy to weld, but you can never restore the heat treated mechanical properties to the welded zones.

It looks to me like you have more damage than just that split. Looks like the spreader also pushed in the side of the mast. I would definately talk to the manufacturer of that mast.

I would have to see the mast to give an accurate opinion as to if you can put a plate on it. From what I can see, it looks like you could sleeve it or replace the mast. I'm not sure about plating. Might work.

dj

So about a year ago, there was a guy on this forum with an H23.5 with a busted ballast tank. You might search the forum and see if you can find him and his contact info. He may be willing to part out his H23.5 if he still has it. It might be easier and cheaper to get a new-used mast.

Welding of the mast would work for the short term, as long as you have a welder with the proper experience. I assume the mast is anodized.

Personally I would look for a used mast as rgranger suggested. Good luck

Personally I would look for a used mast as rgranger suggested. Good luck

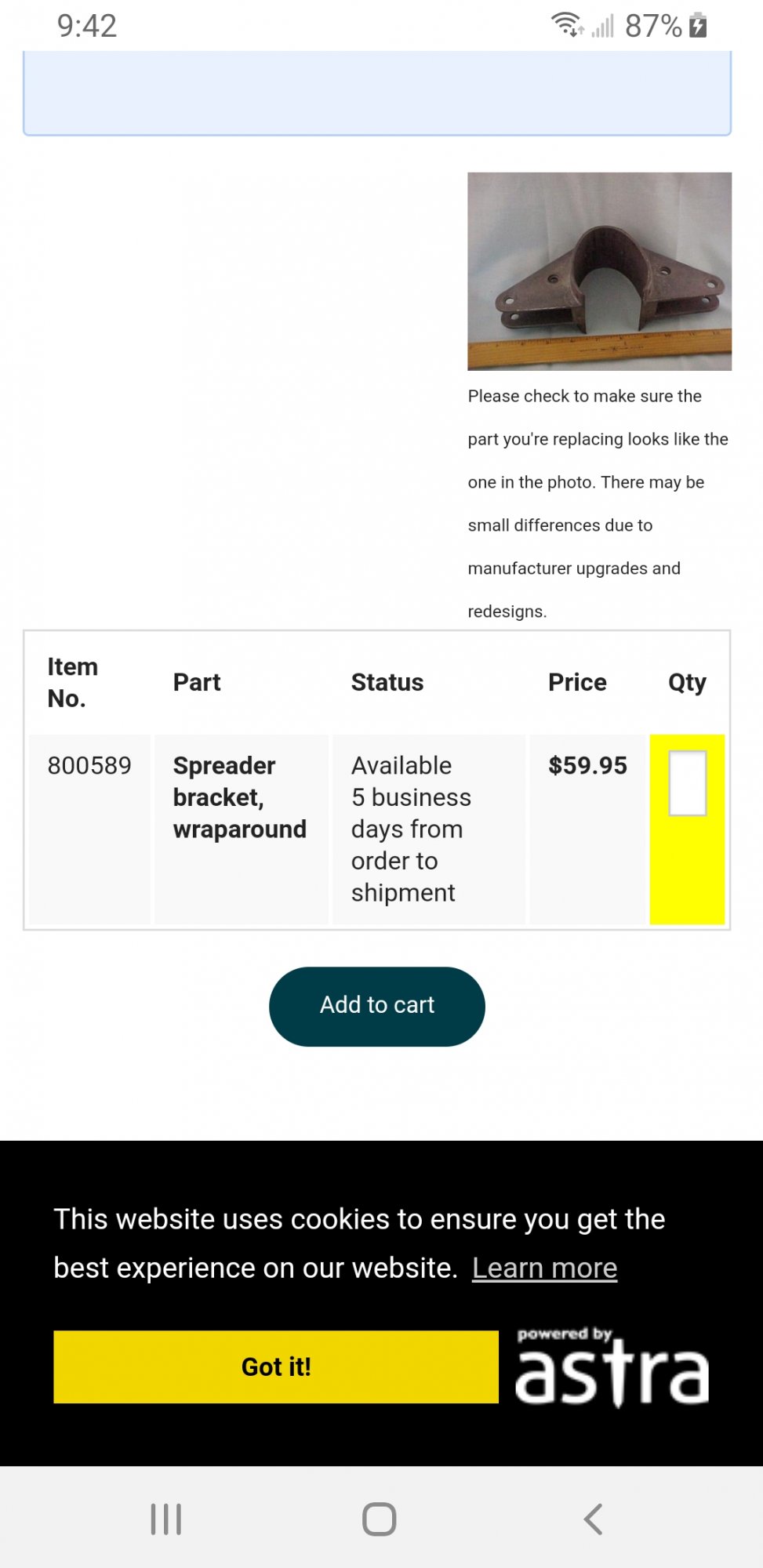

...also, I think the H23.5, H26 and H260 all used Z-spar masts of the same diameter. Yours is definitly the same mast as mine... I replaced my spreader bracket two summers ago and it was exactly like yours (see pic). So you might be able to find an H26 or H260 being parted out and simply cut the mast down and put the end cap back on at the right height.

That is a good idea, I'll look around.So about a year ago, there was a guy on this forum with an H23.5 with a busted ballast tank. You might search the forum and see if you can find him and his contact info. He may be willing to part out his H23.5 if he still has it. It might be easier and cheaper to get a new-used mast.

Sweet! I wish I could have done this two years ago. Nice work- wanna switch masts?...also, I think the H23.5, H26 and H260 all used Z-spar masts of the same diameter. Yours is definitly the same mast as mine... I replaced my spreader bracket two summers ago and it was exactly like yours (see pic). So you might be able to find an H26 or H260 being parted out and simply cut the mast down and put the end cap back on at the right height. View attachment 175229View attachment 175230

Got a 23.5 sitting in my yard taking up space. PM me before I give it away.

There is your answer.... a “boat load” of spare partsGot a 23.5 sitting in my yard taking up space. PM me before I give it away.

Last edited:

Well, any answer I would give you would be for a permanent repair. @DrJudyB suggested if you put a plate on, to bed it in 5200 - an excellent suggestion and one that would allow you not to worry about corrosion at the seams. Splicing the same. I've seen spliced masts last decades.Thanks, DJ. I at least have the option of repair or replace the mast, the latter being much pricier. The only thing I wonder about with repair is will I feel confident with the strength of the repair? Am I going to worry about corrosion with the seams? Any idea how many years I can get out of a repair like this?

I would worry about any fix involving welding as a viable long term solution. I don't do short term, generally...

dj

Got a 23.5 sitting in my yard taking up space. PM me before I give it away.

Well, any answer I would give you would be for a permanent repair. @DrJudyB suggested if you put a plate on, to bed it in 5200 - an excellent suggestion and one that would allow you not to worry about corrosion at the seams. Splicing the same. I've seen spliced masts last decades.

I would worry about any fix involving welding as a viable long term solution. I don't do short term, generally...

dj

Fingers crossed!There is your answer.... a boat load of spare parts