Suggest that you do not remove strut. It is more than just difficult to align. Even with the press tool that you bought you will have a hard time removing the coupling from the shaft. It can be done if you can reach it and you have the patience and strength required. Long weekend, indeed.

Haul Out - Help with my shaft - SoCal

- Thread starter jonelli

- Start date

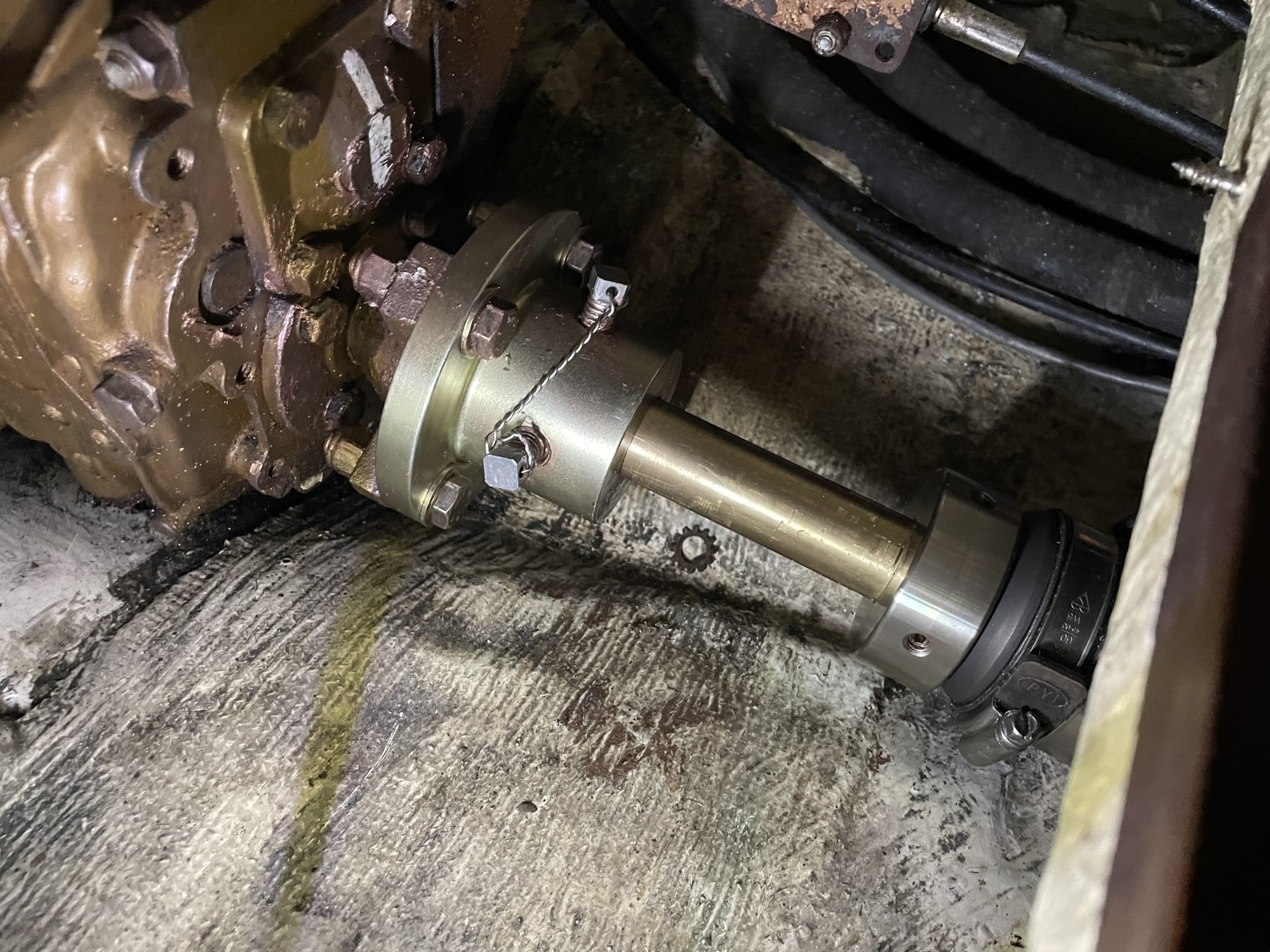

Did you get the short or long one? Does the set screw match the original positions on the original shafts?That looks like the right coupling if the shaft diameter and hole pattern are correct for your boat. I wish they would put a hole in the set screw to be able to safety wire it.

PropShop is just where I bought my coupler The Prop Shop

I'd have to recall some posts but I think mine is short. I think the guy that fit and faced it, notched it for the set screw.Did you get the short or long one? Does the set screw match the original positions on the original shafts?

Just chatted this weekend with one of my buddies that will be helping me. He is a very experience boat guy, and done a lot of this kind of maintenance on many boats, small and large, just not my specific one. He understands the process and how to precision fit and align the coupling, so I feel comfortable there. So, between him and my other buddy who is a qualified machinist type person, I feel we can tackle this.

I am going to try and get the broken set screw out before I haul the boat and make sure I can get all of the bolts loose and get some PB blaster in there well before.

I feel like I have a decent chance of getting the old coupler off since I KNOW that it has previously been removed within the last 10-12 years to get the PSS seal on it. I'm going to purchase a new coupler anyway, so if the old one is unusable, or it won't come off and needs to be cut off, I have a solution to reassemble it using my existing shaft.

I plan on sliding the shaft all the way out, cutting the old cutlass bearing out carefully, and installing a new one using the washer/bolt method, then work on reassembling the shaft, PSS, and coupler.

My timeline will be as follows:

Friday afternoon - haul & pressure wash. scrape hull and tape water line, check for blisters.

Saturday morning - Paint & shaft removal simultaneously with three guys

Remainder of Saturday - shaft and seal work, more paint

Sunday - check and make sure shaft and seal is perfect, anything else that needs to done to the shaft/hull, document any blisters for next time, document dimensions of shaft so a new one can be pre-ordered in the future.

Monday - back in the water.

I am going to try and get the broken set screw out before I haul the boat and make sure I can get all of the bolts loose and get some PB blaster in there well before.

I feel like I have a decent chance of getting the old coupler off since I KNOW that it has previously been removed within the last 10-12 years to get the PSS seal on it. I'm going to purchase a new coupler anyway, so if the old one is unusable, or it won't come off and needs to be cut off, I have a solution to reassemble it using my existing shaft.

I plan on sliding the shaft all the way out, cutting the old cutlass bearing out carefully, and installing a new one using the washer/bolt method, then work on reassembling the shaft, PSS, and coupler.

My timeline will be as follows:

Friday afternoon - haul & pressure wash. scrape hull and tape water line, check for blisters.

Saturday morning - Paint & shaft removal simultaneously with three guys

Remainder of Saturday - shaft and seal work, more paint

Sunday - check and make sure shaft and seal is perfect, anything else that needs to done to the shaft/hull, document any blisters for next time, document dimensions of shaft so a new one can be pre-ordered in the future.

Monday - back in the water.

Sounds like a good plan, but you didn’t leave any room for aJust chatted this weekend with one of my buddies that will be helping me. He is a very experience boat guy, and done a lot of this kind of maintenance on many boats, small and large, just not my specific one. He understands the process and how to precision fit and align the coupling, so I feel comfortable there. So, between him and my other buddy who is a qualified machinist type person, I feel we can tackle this.

I am going to try and get the broken set screw out before I haul the boat and make sure I can get all of the bolts loose and get some PB blaster in there well before.

I feel like I have a decent chance of getting the old coupler off since I KNOW that it has previously been removed within the last 10-12 years to get the PSS seal on it. I'm going to purchase a new coupler anyway, so if the old one is unusable, or it won't come off and needs to be cut off, I have a solution to reassemble it using my existing shaft.

I plan on sliding the shaft all the way out, cutting the old cutlass bearing out carefully, and installing a new one using the washer/bolt method, then work on reassembling the shaft, PSS, and coupler.

My timeline will be as follows:

Friday afternoon - haul & pressure wash. scrape hull and tape water line, check for blisters.

Saturday morning - Paint & shaft removal simultaneously with three guys

Remainder of Saturday - shaft and seal work, more paint

Sunday - check and make sure shaft and seal is perfect, anything else that needs to done to the shaft/hull, document any blisters for next time, document dimensions of shaft so a new one can be pre-ordered in the future.

Monday - back in the water.

.

.Good luck.

Let us know how it goes.

Greg

jssailem

SBO Weather and Forecasting Forum Jim & John

- Oct 22, 2014

- 23,856

Sounds like a decent plan.

May want to leave room for project creep. Seems no matter what preplanned project I have attempted there is always something that happens to extend the time.

For example while you have the boat out you discover a through hull that looks bad and needs replacement. Just roll with what happens and deal with the unexpected.

Good luck.

May want to leave room for project creep. Seems no matter what preplanned project I have attempted there is always something that happens to extend the time.

For example while you have the boat out you discover a through hull that looks bad and needs replacement. Just roll with what happens and deal with the unexpected.

Good luck.

That is what my coupler looked like and after much blood, sweat and tears, I finally had to cut it off with a side-grinder. Once the coupling was off, i was able to remove the shaft without removal of the rudder. I took it to a shaft shop to have a new coupler faced to the shaft and found that the bronze shaft had a bend and had lost zinc so now I have a new SS shaft with split coupling.As of this moment, here's what my coupler looks like. My PSS seal is at least 6 years old, but guessing much longer because the bellows have developed a bit of memory in the position its in and is starting to let water in when moving. It's got a lot of salt crud that keeps building up in there, the surfaces could be scored up, so I'm going to just replace the whole thing with brand new.

No idea if the cutlass bearing is completely gone or fine. But based on the shaft maintenance I've seen, I'm guessing I should just change it while I've got the boat out.

I don't think I have a possibility to dig any holes where the boat will be. So that option is out.

View attachment 191663

I have just purchased a new to me 2004 Catalina 310. Nothing has been done and she’s been in a freshwater lake. 350 hours.

I started the same process myself. Fortunately, I was at a large yard on Lake Texoma with a lot of experienced hands with all the tools.

The job was a bitch even for them. I had the presence of mind to stop DIY almost immediately even though I am the consummate DIYer.

I’d hire it done by a pro who knows how to do it right. He’ll know whether or not you need refacing and any new parts.

Instead of the PSS drip less, I went with the Western Pacific Trading Teflon like drip less packing for my standard stuffing box.

I expected to have this done in a short time, but it’s one of the biggest projects I have seen.It was easier to pull the engine.

I started the same process myself. Fortunately, I was at a large yard on Lake Texoma with a lot of experienced hands with all the tools.

The job was a bitch even for them. I had the presence of mind to stop DIY almost immediately even though I am the consummate DIYer.

I’d hire it done by a pro who knows how to do it right. He’ll know whether or not you need refacing and any new parts.

Instead of the PSS drip less, I went with the Western Pacific Trading Teflon like drip less packing for my standard stuffing box.

I expected to have this done in a short time, but it’s one of the biggest projects I have seen.It was easier to pull the engine.

Well, despite all the warnings, we were able to get the shaft out of the coupler using the $50 tool from CD.

And then, with a hacksaw blade and some chisels, we peeled the old cutlass bearing out. No set screws found in this strut.

Pressing the new cutlass went in smoothly. Kept it on ice all morning, used a 10" 7/8 bolt, some washers and nuts and pressed it right in.

.

After some shaft polishing, we fitted the new coupler and lined everything up.

The alignment is no worse than it was before we started, but I'm going to further check it now that it's all back in the water.

And then, with a hacksaw blade and some chisels, we peeled the old cutlass bearing out. No set screws found in this strut.

Pressing the new cutlass went in smoothly. Kept it on ice all morning, used a 10" 7/8 bolt, some washers and nuts and pressed it right in.

.

After some shaft polishing, we fitted the new coupler and lined everything up.

The alignment is no worse than it was before we started, but I'm going to further check it now that it's all back in the water.