I used the recommended grease from Volvo. Use a regular drinking straw & fill it with grease. Place the end of the straw under the edge of the shaft seal & extrude the grease into the seal. Mine is now 10 years old & doesn't drip at all; however, I have low hours on the drive train. I believe that the recommended replacement interval is 10 years.

Check your stern tube water nipple

- Thread starter Gunni

- Start date

The same waterproof grease I use to lube my MaxProp. I draw some grease up into a West System epoxy syringe and use that on the Volvo seal. The syringe stows nicely next to the shaft - right where you need it.I asked this before but haven't got an answer. What do you guys use to grease the Volvo seal?

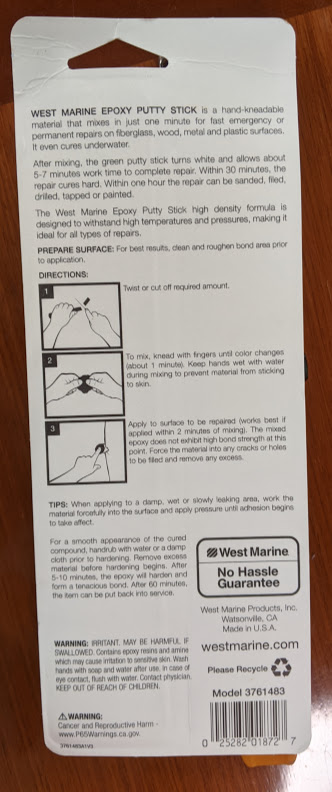

Here is something that might help if your shaft nipple breaks off when the boat is in the water! I just tapped mine and it broke off (see picture) and water spurts in, not a lot but about a pencil diameter and about as high. I had one of those orange foam plugs that I jammed in and that stopped the water for a couple of days while I attended to my other projects. I did not want to put another brass nipple in so I bought a couple of ss nipples 1/8" NPT threads with 3/8" hose barb on the other end from stainlesssteelfittings.com (see picture 2). Then I bought some of the West Marine Epoxy Putty Stick and decided to tackle this project knowing I could drive the boat over to the Marina with a Travel Lift and for $300 they would short-haul me out for a couple of hours.

So I decided to drill out the shaft log with a drill bit a little smaller than the 1/8" NPT threads on the nipple which are really about 3/8" inch in diameter. I used a 23/64" drill bit, not really too much water coming at me, and I did not have to worry about any chips staying in the hole! Just be careful and drill slowly since the shaft tube is pretty thin. I put the orange plug back in while I planned the next step. So take a short length of hose and just barely put it on the nipple (no hose clamp need, you just want to be able to gently pull it off when you are done, I used a little bit of grease). Next, I took a 3/8" clevis pin and a small hose clamp to close off the other end of the tubing so it would not leak seawater. I then used some 100 grit gray emery cloth sandpaper and roughed up the shaft log near the hole so the epoxy would bond better. Now you can "dry fit" your new nipple by removing the foam plug and push down slightly on the nipple so you can cut some threads into the shaft log, I used a little open-end wrench and gave it about 2 1/2 turns and most all the water stopped coming in! Next, I mixed up about a 3/4" square amount of the Epoxy putty (keep your hands wet while working with this) by kneading it in my hands. Now you just make a "snake" about 4-5" long and slowly wrap it around your nipple. It does not stick well at first but after about 2 minutes (keep your hands moist) it starts gripping the nipple and the shaft log. Keep pushing and kneading the putty for a couple more minutes and you should be able to make a nice little fillet (see picture). After an hour or so very carefully take off your short piece of hose and attach your longer piece of hose. I did not install

the hose clamps until the following day since my tubing was pretty tight on the nipple and no leaking. Needless to say, I am a believer in West Marine's Epoxy Putty Stick!

the hose clamps until the following day since my tubing was pretty tight on the nipple and no leaking. Needless to say, I am a believer in West Marine's Epoxy Putty Stick!

So I decided to drill out the shaft log with a drill bit a little smaller than the 1/8" NPT threads on the nipple which are really about 3/8" inch in diameter. I used a 23/64" drill bit, not really too much water coming at me, and I did not have to worry about any chips staying in the hole! Just be careful and drill slowly since the shaft tube is pretty thin. I put the orange plug back in while I planned the next step. So take a short length of hose and just barely put it on the nipple (no hose clamp need, you just want to be able to gently pull it off when you are done, I used a little bit of grease). Next, I took a 3/8" clevis pin and a small hose clamp to close off the other end of the tubing so it would not leak seawater. I then used some 100 grit gray emery cloth sandpaper and roughed up the shaft log near the hole so the epoxy would bond better. Now you can "dry fit" your new nipple by removing the foam plug and push down slightly on the nipple so you can cut some threads into the shaft log, I used a little open-end wrench and gave it about 2 1/2 turns and most all the water stopped coming in! Next, I mixed up about a 3/4" square amount of the Epoxy putty (keep your hands wet while working with this) by kneading it in my hands. Now you just make a "snake" about 4-5" long and slowly wrap it around your nipple. It does not stick well at first but after about 2 minutes (keep your hands moist) it starts gripping the nipple and the shaft log. Keep pushing and kneading the putty for a couple more minutes and you should be able to make a nice little fillet (see picture). After an hour or so very carefully take off your short piece of hose and attach your longer piece of hose. I did not install

Last edited:

While this is an old thread, I’m amazed at the number of affected boats and that I’ve not heard of more water damage as the incoming water is more than a trickle.

After my fitting fell off with the slightest touch, I’m planning to glass over the hole and install a seal that has a fitting firmly attached into metal. The PSS looks like a great option vs this ridiculous engineering from the factory. I believe the 3/8” hose was glued to the fitting which required cutting the hose off.

There‘s a debate whether the Volvo seal really needs additional cooling water at sailboat speeds. I’m aware of one captain that says he hasn’t had cooling for years and the Volvo is working just fine. No heat being generated.

After my fitting fell off with the slightest touch, I’m planning to glass over the hole and install a seal that has a fitting firmly attached into metal. The PSS looks like a great option vs this ridiculous engineering from the factory. I believe the 3/8” hose was glued to the fitting which required cutting the hose off.

There‘s a debate whether the Volvo seal really needs additional cooling water at sailboat speeds. I’m aware of one captain that says he hasn’t had cooling for years and the Volvo is working just fine. No heat being generated.

Last edited:

Except the fitting is not to cool the volvo dripless...It's to flow water thru the cutless as it is inbeded into the skeg. Older beneteaus with a strut have no water flow to dripless, and I have install Volvo dripless on a few CS36's years ago and no issues no water flow , the lips just require greaseWhile this is an old thread, I’m amazed at the number of affected boats and that I’ve not heard of more water damage as the incoming water is more than a trickle.

After my fitting fell off with the slightest touch, I’m planning to glass over the hole and install a seal that has a fitting firmly attached into metal. The FFS looks like a great option vs this ridiculous engineering from the factory. I believe the 3/8” hose was glued to the fitting which required cutting the hose off.

There‘s a debate whether the Volvo seal really needs additional cooling water at sailboat speeds. I’m aware of one captain that says he hasn’t had cooling for years and the Volvo is working just fine. No heat being generated.

It is a ridiculous factory instal but an easy fix to make permanent. I used a ss fitting I bought from McMaster-Carr and a bit of epoxy. And yes the water feed is for the cutlass as the stern tube has the cutlass at the end and minimal water can get through. Also I love the volvo seal. Simple, inexpensive, easy to replace (once you get the coupling off) and works flawlessly.

But you put the epoxy putty on the volvo seal......... at some point in time it will have to be removed.Here is something that might help if your shaft nipple breaks off when the boat is in the water! I just tapped mine and it broke off (see picture) and water spurts in, not a lot but about a pencil diameter and about as high. I had one of those orange foam plugs that I jammed in and that stopped the water for a couple of days while I attended to my other projects. I did not want to put another brass nipple in so I bought a couple of ss nipples 1/8" NPT threads with 3/8" hose barb on the other end from stainlesssteelfittings.com (see picture 2). Then I bought some of the West Marine Epoxy Putty Stick and decided to tackle this project knowing I could drive the boat over to the Marina with a Travel Lift and for $300 they would short-haul me out for a couple of hours.

So I decided to drill out the shaft log with a drill bit a little smaller than the 1/8" NPT threads on the nipple which are really about 3/8" inch in diameter. I used a 23/64" drill bit, not really too much water coming at me, and I did not have to worry about any chips staying in the hole! Just be careful and drill slowly since the shaft tube is pretty thin. I put the orange plug back in while I planned the next step. So take a short length of hose and just barely put it on the nipple (no hose clamp need, you just want to be able to gently pull it off when you are done, I used a little bit of grease). Next, I took a 3/8" clevis pin and a small hose clamp to close off the other end of the tubing so it would not leak seawater. I then used some 100 grit gray emery cloth sandpaper and roughed up the shaft log near the hole so the epoxy would bond better. Now you can "dry fit" your new nipple by removing the foam plug and push down slightly on the nipple so you can cut some threads into the shaft log, I used a little open-end wrench and gave it about 2 1/2 turns and most all the water stopped coming in! Next, I mixed up about a 3/4" square amount of the Epoxy putty (keep your hands wet while working with this) by kneading it in my hands. Now you just make a "snake" about 4-5" long and slowly wrap it around your nipple. It does not stick well at first but after about 2 minutes (keep your hands moist) it starts gripping the nipple and the shaft log. Keep pushing and kneading the putty for a couple more minutes and you should be able to make a nice little fillet (see picture). After an hour or so very carefully take off your short piece of hose and attach your longer piece of hose. I did not installView attachment 174567View attachment 174568View attachment 174569View attachment 174570View attachment 174571 the hose clamps until the following day since my tubing was pretty tight on the nipple and no leaking. Needless to say, I am a believer in West Marine's Epoxy Putty Stick!View attachment 174573