I have a 2009 49, on my electric blige pump discharge there is a one way valve is this a factory install or did the previous owner put it on.

Check Valve

- Thread starter RHUMB RUNNER

- Start date

- Status

- Not open for further replies.

Which type of pump?

I think there is a small check valve on the Johnson pump.

I don't like check valves on bilge pumps.

Too much back pressure up a steep climb of hose.

Only reason people put them in is to keep the run back out of the bilge.

This never works, cause they leak anyway.

Better off to remove it

Do you have the Johnson pump (red), or white pump?I have a 2009 49, on my electric blige pump discharge there is a one way valve is this a factory install or did the previous owner put it on.

I think there is a small check valve on the Johnson pump.

I don't like check valves on bilge pumps.

Too much back pressure up a steep climb of hose.

Only reason people put them in is to keep the run back out of the bilge.

This never works, cause they leak anyway.

Better off to remove it

The pump is a Rule and the check valve is up the hose about a foot from the pump. On another subject does your galley sink drain run slow, I cleaned the hoses out and it still drains slow. The two sinks our connected by a tee not a Y, I thought this might be part of the problem.

My 34 came with a check valve in the bilge discharge line. The volume in the long discharge hose (about 10 feet) is more than the volume of the shallow bilge sump.. If the valve were not there, the pump would cycle on and off constantly .. I am not happy with this arrangement but with the very shallow bilge, it is about the only way to have the bilge reasonably empty. I have had only one failure of the PVC check valve in the 21 years I've owned the boat. The problem was that I let a piece of wire insulation (from making a connection) fall into the bilge. The little nub of wire stuck under the check valve internal plate. I cleaned it and it continues to be OK.. I carry a spare valve. I don't know if the ABYC standards still allow such a thing on new boats..??

Check valves have absolutely no negative affect on the bilge pump. Pumping water is based on head which is the total vertical rise you are pumping the water. The head is the same weather you have a check valve or not.

Without the check valve you would have the pump turn on based on the float switch and pump water until the float went down, shutting off the pump. The water in the house, in the case of a Catalina 310 about 1 gallon, will then call back into the bilge, probably causing the pump to cycle back on.

Don't remove the check valve. Use Brass instead of plastic. And use a "flapper" style instead of a spring style. The flapper style has a clean out opening that can be removed so you can clean the flapper and the shelf it sits on.

By the way, just to give you a little credentials. I am an environmental consultant and manage construction for a major oil company. I probably pump over ten billion gallons of contaminated water each year. I have had to learn a lot about pumps over the 17 years I have been doing this.

Without the check valve you would have the pump turn on based on the float switch and pump water until the float went down, shutting off the pump. The water in the house, in the case of a Catalina 310 about 1 gallon, will then call back into the bilge, probably causing the pump to cycle back on.

Don't remove the check valve. Use Brass instead of plastic. And use a "flapper" style instead of a spring style. The flapper style has a clean out opening that can be removed so you can clean the flapper and the shelf it sits on.

By the way, just to give you a little credentials. I am an environmental consultant and manage construction for a major oil company. I probably pump over ten billion gallons of contaminated water each year. I have had to learn a lot about pumps over the 17 years I have been doing this.

Probably the first day I took delivery of my 49 I ditched the 'T' in the sink drain.does your galley sink drain run slow, I cleaned the hoses out and it still drains slow. The two sinks our connected by a tee not a Y, I thought this might be part of the problem.

You may have a air block in the line. I get this every year when I relaunch the boat. What I do is loosen the clamps at the sea-cock to let the air bleed out. That usually takes care of the issue. They do drain slow anyway do to the head pressure on the line.

Thanks for your response but...

Can't tell you the number of boats I've been on where the check valve on a bilge pump caused it to fail.

It does so for 2 reasons:

The force on the check valve is greater than what the pump can generate to open the flapper when the entire pipe is filled with water.

This is mostly owing to boat builders fitting marginal bilge pumps.

As well, if you have a check valve, and you get an air lock between the pump and input to the check, the pump will not build up enough output pressure to break the check valve open.

This happens a lot with boat airco pumps as well, when they put a check in the output.

I'm sure you know a lot about pumps. But I've seen many instances where a check is mounted outside a pump where it will block the output.

Your're wrong.Check valves have absolutely no negative affect on the bilge pump. Pumping water is based on head which is the total vertical rise you are pumping the water. The head is the same weather you have a check valve or not.

Without the check valve you would have the pump turn on based on the float switch and pump water until the float went down, shutting off the pump. The water in the house, in the case of a Catalina 310 about 1 gallon, will then call back into the bilge, probably causing the pump to cycle back on.

Don't remove the check valve. Use Brass instead of plastic. And use a "flapper" style instead of a spring style. The flapper style has a clean out opening that can be removed so you can clean the flapper and the shelf it sits on.

By the way, just to give you a little credentials. I am an environmental consultant and manage construction for a major oil company. I probably pump over ten billion gallons of contaminated water each year. I have had to learn a lot about pumps over the 17 years I have been doing this.

Can't tell you the number of boats I've been on where the check valve on a bilge pump caused it to fail.

It does so for 2 reasons:

The force on the check valve is greater than what the pump can generate to open the flapper when the entire pipe is filled with water.

This is mostly owing to boat builders fitting marginal bilge pumps.

As well, if you have a check valve, and you get an air lock between the pump and input to the check, the pump will not build up enough output pressure to break the check valve open.

This happens a lot with boat airco pumps as well, when they put a check in the output.

I'm sure you know a lot about pumps. But I've seen many instances where a check is mounted outside a pump where it will block the output.

I got rid of the y valveProbably the first day I took delivery of my 49 I ditched the 'T' in the sink drain.

You may have a air block in the line. I get this every year when I relaunch the boat. What I do is loosen the clamps at the sea-cock to let the air bleed out. That usually takes care of the issue. They do drain slow anyway do to the head pressure on the line.

Put in a separate through hull for the aft head sink.

This is really the only proper solution I'm afraid.

Head is head for pumps. If it can pump the water out without a check valve then it can with. The pressure required to open the check valve is the same as the pressure required to push the water column without it.Your're wrong.

Can't tell you the number of boats I've been on where the check valve on a bilge pump caused it to fail.

It does so for 2 reasons:

The force on the check valve is greater than what the pump can generate to open the flapper when the entire pipe is filled with water.

This is mostly owing to boat builders fitting marginal bilge pumps.

As well, if you have a check valve, and you get an air lock between the pump and input to the check, the pump will not build up enough output pressure to break the check valve open.

This happens a lot with boat airco pumps as well, when they put a check in the output.

I'm sure you know a lot about pumps. But I've seen many instances where a check is mounted outside a pump where it will block the output.

The check valve simply prevents the water from falling back down the pipe.

The air bound situation you are describing is usually the result of poor maintenance of the check valve.

I am not sure what you mean by marginal pumps from boat builders. Are you saying they are undersized or poor quality?

I am no expert on pumps or check valves but it would seem to me most check valves I have used reduce the size of the line somewhat and that would increase back pressure and so reduce flow. I am sure they would introduce introduce turbulence that should also increase back pressure. Even a 90* elbow will reduce flow in a pipe ?

I suppose it only really matters if the pump can't keep up with the water coming into the boat, just to handle everyday stuff maximum flow is not so important...but if you are sinking maybe that little extra might save the day

Bob

I suppose it only really matters if the pump can't keep up with the water coming into the boat, just to handle everyday stuff maximum flow is not so important...but if you are sinking maybe that little extra might save the day

Bob

Your probably right about that. I routed that vanity sink to the shower sump. But going directly overboard is probably a cleaner solution (excuse the pun). Using one of those Whale IC grey water pumps with two inputs would even be better (shower / Vanity sink)I got rid of the y valve

Put in a separate through hull for the aft head sink.

This is really the only proper solution I'm afraid.

Revised Answer

OK, I thought about the original post and my two responses and thought I needed to do a non-iPhone answer to clarify my thoughts.

Most, and I stress most, electric bilge pumps are centrifugal pumps. This means there is a plastic impeller that spins to create the pressure to push water up the discharge hose. These pumps are not self-priming but installing them in the bottom of the bilge deals with this issue and for this application, gravity forcing water into the bilge naturally provides the priming. This type of pump would include in the Rule Bilge Pump series that I believe is the most common on production boats. My Catalina 310 came with a 500 gph Rule Bilge Pump controlled by a Rule-a-matic mechanical float switch. From what I found by looking at a Hunter 49 online, it appears they came with two pumps, a 1500 and a 2000 gph Rule Bilge Pump, installed. So I am not sure which pump the OP was referencing but I believe it is the 1500 gph because that appears to be the "maintenance" pump and the 2000 gph is the emergency pump.

I have attached the pump curves for both the "small" and "large" series of Rule Bilge Pumps. Based on these pump curves, you can determine the efficiency of the pump based on the head (shown as "height in feet"). The head is how many vertical feet your pump has to go to exit the boat.

We will use my Catalina for this example because I don't know the details for the Hunter. Exiting the pump, there is an approximately 10 inch vertical rise, let's call it a foot. The discharge hose then runs horizontally from the bilge to the stern where it enters a mechanical space with my water heater, holding tank, etc. In this area it has a vertical rise of approximately 2.5 feet. (See bilge pump diagram I uploaded.) So that is a total of 3.5 feet of vertical rise. Based on the pump curve, my 500 gph pump will be pumping at approximately 400 gph.

Now, with a check valve, you will have the weight of the water above the valve that will add head. As I mentioned before, my Catalina holds one gallon in the hose above the check valve (approximately 30 feet of 3/4" diameter hose). Actually it is 0.69 of a gallon. That's 5.9 pounds of salt water. The full volume over the surface area of the check valve (0.75-inch diameter) that's 13.36 psi for the whole water column. However it would actually only be for the volume of water in the vertical section of the pipe. That would be 3.5 feet out of 30 feet, so only 11% of that total, or 1.5 psi, would actually be adding to the head. When you convert psi to head that equals an additional 3.5 feet of head (funny how that equals the same as our initial head, we just proved how to derive head pressure). So again consult the pump curve and that would be a total of seven feet of head and bring the pumping efficiency down to 250 gph. Now, this would only be until the first slug of water is pushed pass the check valve. Once the first slug is past the check valve, it goes back to the initial head pressure. If the check valve was 2 feet from the bilge pump (usually much closer than this), that would mean 0.00076 gallons between the pump and the check valve. So the pump would pump for 0.00108 seconds at 250 gph before increasing to 400 gph.

So taking a quick look at the Hunter, you would need 6 feet of vertical rise above the check valve before you would dead-head the pump (reduce the effluent to 0 gph) for the 1500 gph pump and 10.5 feet for the 2000 gph pump.

The air bound problem described by artboas occurs due to poor maintenance. All check valves, even PVC ones, have metal parts on the interior. When used in the application of salt water, they will rust and seize. This is the problem with check valves on boats. A flap style will seize closed. A spring style will seize open. My spring style on my hot water heater seized open last year and I had to replace it before I could winterize the potable water system. They can also malfunction due to debris pumped from the bilge.

This is why I recommend using a brass flapper style and that needs to be maintained. I inspect mine annually and clean and debris that would prevent the flapper from sealing.

The negatives of not have a check valve is that every time the pump stops, water flows back down into the bilge. On top of being a nuisance for those trying to keep a dry bilge, it causes the impeller to turn in the opposite direction as designed and causes wear. It will eventually cause your pump to fail.

There are other types of pumps, I think artboas mentioned air conditioner pumps. Those are also typically centrifugal pumps. However, their application does not allow for the backflow issue typical of bilge pumps. So most of the time you should not need a check valve.

I hope this helps some understand this issue.

Fair winds,

Jesse

OK, I thought about the original post and my two responses and thought I needed to do a non-iPhone answer to clarify my thoughts.

Most, and I stress most, electric bilge pumps are centrifugal pumps. This means there is a plastic impeller that spins to create the pressure to push water up the discharge hose. These pumps are not self-priming but installing them in the bottom of the bilge deals with this issue and for this application, gravity forcing water into the bilge naturally provides the priming. This type of pump would include in the Rule Bilge Pump series that I believe is the most common on production boats. My Catalina 310 came with a 500 gph Rule Bilge Pump controlled by a Rule-a-matic mechanical float switch. From what I found by looking at a Hunter 49 online, it appears they came with two pumps, a 1500 and a 2000 gph Rule Bilge Pump, installed. So I am not sure which pump the OP was referencing but I believe it is the 1500 gph because that appears to be the "maintenance" pump and the 2000 gph is the emergency pump.

I have attached the pump curves for both the "small" and "large" series of Rule Bilge Pumps. Based on these pump curves, you can determine the efficiency of the pump based on the head (shown as "height in feet"). The head is how many vertical feet your pump has to go to exit the boat.

We will use my Catalina for this example because I don't know the details for the Hunter. Exiting the pump, there is an approximately 10 inch vertical rise, let's call it a foot. The discharge hose then runs horizontally from the bilge to the stern where it enters a mechanical space with my water heater, holding tank, etc. In this area it has a vertical rise of approximately 2.5 feet. (See bilge pump diagram I uploaded.) So that is a total of 3.5 feet of vertical rise. Based on the pump curve, my 500 gph pump will be pumping at approximately 400 gph.

Now, with a check valve, you will have the weight of the water above the valve that will add head. As I mentioned before, my Catalina holds one gallon in the hose above the check valve (approximately 30 feet of 3/4" diameter hose). Actually it is 0.69 of a gallon. That's 5.9 pounds of salt water. The full volume over the surface area of the check valve (0.75-inch diameter) that's 13.36 psi for the whole water column. However it would actually only be for the volume of water in the vertical section of the pipe. That would be 3.5 feet out of 30 feet, so only 11% of that total, or 1.5 psi, would actually be adding to the head. When you convert psi to head that equals an additional 3.5 feet of head (funny how that equals the same as our initial head, we just proved how to derive head pressure). So again consult the pump curve and that would be a total of seven feet of head and bring the pumping efficiency down to 250 gph. Now, this would only be until the first slug of water is pushed pass the check valve. Once the first slug is past the check valve, it goes back to the initial head pressure. If the check valve was 2 feet from the bilge pump (usually much closer than this), that would mean 0.00076 gallons between the pump and the check valve. So the pump would pump for 0.00108 seconds at 250 gph before increasing to 400 gph.

So taking a quick look at the Hunter, you would need 6 feet of vertical rise above the check valve before you would dead-head the pump (reduce the effluent to 0 gph) for the 1500 gph pump and 10.5 feet for the 2000 gph pump.

The air bound problem described by artboas occurs due to poor maintenance. All check valves, even PVC ones, have metal parts on the interior. When used in the application of salt water, they will rust and seize. This is the problem with check valves on boats. A flap style will seize closed. A spring style will seize open. My spring style on my hot water heater seized open last year and I had to replace it before I could winterize the potable water system. They can also malfunction due to debris pumped from the bilge.

This is why I recommend using a brass flapper style and that needs to be maintained. I inspect mine annually and clean and debris that would prevent the flapper from sealing.

The negatives of not have a check valve is that every time the pump stops, water flows back down into the bilge. On top of being a nuisance for those trying to keep a dry bilge, it causes the impeller to turn in the opposite direction as designed and causes wear. It will eventually cause your pump to fail.

There are other types of pumps, I think artboas mentioned air conditioner pumps. Those are also typically centrifugal pumps. However, their application does not allow for the backflow issue typical of bilge pumps. So most of the time you should not need a check valve.

I hope this helps some understand this issue.

Fair winds,

Jesse

Attachments

-

46.1 KB Views: 281

-

46.5 KB Views: 333

-

164.2 KB Views: 338

JK none of this applies well to the crappy centrifugal pumps we use for bilge pumps. If you want to put one on a considerably more expensive diaphraghm pump, go ahead, but I would never advise a check valve on a Rule style pump, even to my worst enemy.Check valves have absolutely no negative affect on the bilge pump. Pumping water is based on head which is the total vertical rise you are pumping the water. The head is the same weather you have a check valve or not.

Without the check valve you would have the pump turn on based on the float switch and pump water until the float went down, shutting off the pump. The water in the house, in the case of a Catalina 310 about 1 gallon, will then call back into the bilge, probably causing the pump to cycle back on.

Don't remove the check valve. Use Brass instead of plastic. And use a "flapper" style instead of a spring style. The flapper style has a clean out opening that can be removed so you can clean the flapper and the shelf it sits on.

By the way, just to give you a little credentials. I am an environmental consultant and manage construction for a major oil company. I probably pump over ten billion gallons of contaminated water each year. I have had to learn a lot about pumps over the 17 years I have been doing this.

Check valves DO CAUSE PROBLEMS. They kill battery banks, gum up and stick and refuse to open due to the standing water in the hose. They also almost always eventually "drain back" because they really suck at "checking".

These valves quite often stick shut especially if the bilge pump does not cycle often. It is the number ONE cause of bilge pump nuisance calls I get called to fix. The biggest draw back is the added head pressure that the pump can not overcome during start up if the check valve actually "checked" and held the water in the line.. This head is caused by the standing water in the discharge hose, and thus, a centrifugal pump will very often simply cavitate and do nothing but make some neat little bubbles in the bilge. Once the little bubbles start the check valve never opens and the bilge pump kills the bank or burns out, which ever comes first.

For boats stored in-water during cold weather the water in the bilge hose above bilge level can freeze, even when the bilge water is not frozen. This presents an impossible situation to pump into. I have seen this occur and the danger is real.

Fill a grain silo with corn and then try to push a door open into it...... Pretty tough. The check valve creates a similar resistance to the bilge pump when it starts, Centrifugal pumps deal horribly with any added head pressure especially on start up... Flappers work marginally better than springs but both cause a tremendous number of bilge pump failures leading to killed batteries or damaged boats.

Check valves on rotary vane pumps or diaphragm pumps do not suffer the issues they do on centrifugal Rule style pumps. I have seen everything from ruined interior cabinetry, cabin soles and engines due to stuck check valves. They are a Band-Aid to a poorly designed bilge pumping system. I have also seen boats that sank because of a stuck check valve.. One of my customers lost nearly 60k in brand new Honda outboards because the check valve stuck and his sport fishing boat went glug, glug...

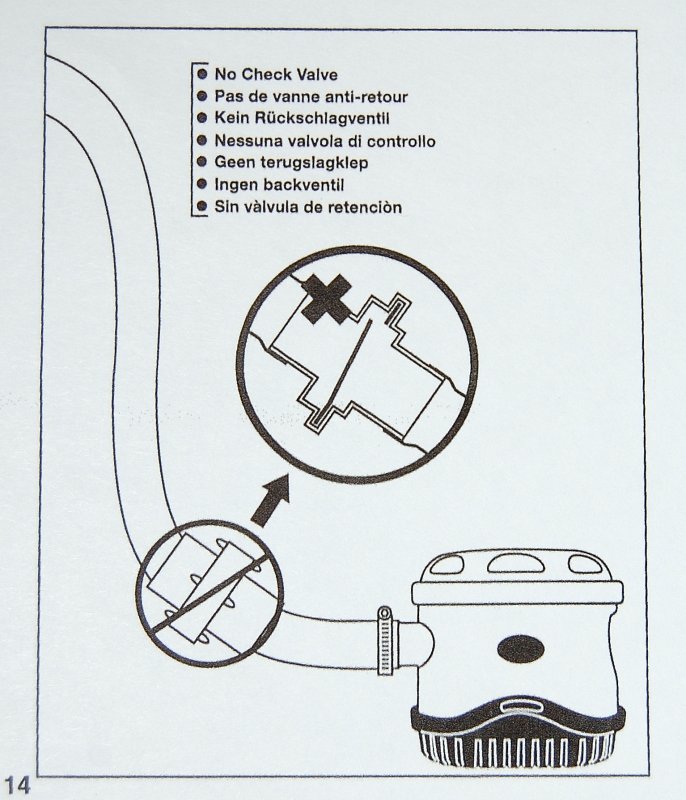

The largest maker of centrifugal bilge pumps, Rule, specifically recommends not to use them.

They can be a danger if used on a system with centrifugal bilge pump. Bilge pumps are safety items anything that can prevent the pump from pumping becomes a potential danger.

Rule Pump Instructions

If you want to use a two pump system a "nuisance pump" and a "primary" pump then a check valve can be fitted to the lower nuisance water pump. They still stick and kill batteries though...

I would NEVER, and I don't use the word never often, recommend a check valve on a single pump installation when a centrifugal pump is being used. If you want a check valve you'd be well served to use a rotary vane or diaphragm pump that has the ability to deal with the head pressure of the standing water and to push open a sticky gummed up check valve... These are NOT industrial pumps they are little 12V toy pumps masquerading as "bilge pumps". They are cheap and can work ok when properly installed so they are very popular. Centrifugal pumps with check valves often just make neat little bubbles and the water remains in the bilge and the batteries die.

Centrifugal pumps with check valves are a danger waiting to happen, I see it and fix it regularly. You would be horrified at the number of "check valves" I see that fail to open. I am the guy replacing the batteries, that the bilge pump killed, when the check valve stuck and the float switch remained ON.........

Also keep in mind that the voltage at the pump makes another HUGE dent in performance of these pumps. The Rule graphs are "optimistic" at best. Suffice it to say that a Rule 2000, when installed in a sailboat, with the crappy corrugated hose most often used, may not even pump 25% of its face value rating...

Most of the centrifugal pumps are rated at "open bucket" (which means NO HEAD) and at CHARGING VOLTAGES... This is misleading and deceptive to the consumer who believes they are getting a 500GPH pump when in fact they may likely never pump more than 200GPH as installed. Very often the little but expensive diaphragm pump with the $hitty GPH rating will outperform the centrifugal pump when "installed"... Expensive yachts use diaphragm pumps but also often have reserve capacity with Rule style pumps.

I had this saved from years ago when a customers boat nearly sank due to a stuck check valve. He had some bad interior damage requiring massive refinishing. When I showed up the surveyor, owner and boat yard mechanic were there and no-one could figure out the "issue" or what caused the issue. I took one look in the bilge, grabbed a hose and began to fill it. The bilge pump just made bubbles. Problem solved, stuck check valve. Still had to replace the cracked sanitation hose that caused the leak too.

"The Rule Pump FAQs

Can I install a check valve on the pump discharge?

Check valves are not recommended

Why doesn't Rule pump want check valve on the pump's discharge?

Check valves are prohibited by the American Boat & Yacht Council for use as an anti-siphon device-and with good reason: They're notorious for failing in both the open and the closed position, which respectively leads to flooding or failure to pump. If the valve is close to the pump, the pump may not be able to overcome the weight of the water on the other side of the valve, rendering the pump ineffective.

Why does my automatic Rule Pumps turns off if I install a check valve on the discharge of the pump?

The automatic bilge pump turns on about every two and a half minutes to "check" for high water. If water causes resistance on the pump, it continues to pump until the resistance lowers. With the check valve installed at the pump, it cant feel the weight of the water, and shuts off, allowing the bilge to fill with water!"

Rule must have read my mind....

Well, clearly I stand corrected.

This just shows that experience trumps all. And my experience with construction/industrial equipment is not as good as experience with marine applications.

Very disappointed to learn that Rule puts out false pump curves. Also I am disappointed that Catalina would put a check valve in with the information you have cited.

I am now making plans to rip out my Rule and replace it with something better. Any suggestions?

Thanks as always MS.

This just shows that experience trumps all. And my experience with construction/industrial equipment is not as good as experience with marine applications.

Very disappointed to learn that Rule puts out false pump curves. Also I am disappointed that Catalina would put a check valve in with the information you have cited.

I am now making plans to rip out my Rule and replace it with something better. Any suggestions?

Thanks as always MS.

Just different applications. In theory the data you present is fine, and quite accurate, when the variables are met. In the real world it does not account for bilge chemicals, oil, etc. softening the seals, or the corrugated hose or low voltages, or elbows, reducers etc....They work in big industrial pumps, used to be a rep for Zoeller, but on boats they can be a true danger.Well, clearly I stand corrected.

This just shows that experience trumps all. And my experience with construction/industrial equipment is not as good as experience with marine applications.

Very disappointed to learn that Rule puts out false pump curves. Also I am disappointed that Catalina would put a check valve in with the information you have cited.

I am now making plans to rip out my Rule and replace it with something better. Any suggestions?

Thanks as always MS.

The Rule curves are probably accurate for "lab" data but lab data and real world data hardly ever mesh up.. Hell Trojan claims 1200 cycles from a T105 but the only place that will ever happen is in the lab with the guys with white coats. On boats they rarely if ever even get to half that. Misleading? IMHO yes but if they can do that in the "lab" well.....

Don't rip out the Rule just add a good diaphragm pump and keep the Rule as back up...

Thanks guy's,

The main question was does anyone know if Hunter put the check valve in at the factory.

The main question was does anyone know if Hunter put the check valve in at the factory.

In all due respect

Perhaps in theory they work, but in practice, they are your worst enemy.

The best setup in the world is what Hunter does on the larger boats: two pumps, with a high water alarm on the high water pump.

My original position, which was clearly backed up is that "stay away from check valves on bilge pumps"to the main question No

Perhaps in theory they work, but in practice, they are your worst enemy.

The best setup in the world is what Hunter does on the larger boats: two pumps, with a high water alarm on the high water pump.

JK, I always assumed that Catalina put the check valve in the bilge pump circuit because it shares the outlet with the manual diaphragm pump. Without the check valve, the manual pump would be pumping water back into the bilge through the Rule pump. Does this make sense?Well, clearly I stand corrected.

This just shows that experience trumps all. And my experience with construction/industrial equipment is not as good as experience with marine applications.

Very disappointed to learn that Rule puts out false pump curves. Also I am disappointed that Catalina would put a check valve in with the information you have cited.

I am now making plans to rip out my Rule and replace it with something better. Any suggestions?

Thanks as always MS.

BTW, I did install a high water alarm for those times when the check valve gets stuck.

- Status

- Not open for further replies.