My large thru hull black water discharge shut off valve has some small amounts of greenish mold like areas and from the condensation in the V-berth where it is located. My intentions, good, bad or indifferent, are to firstly air out the area, hang a moisture bag before firstly cleaning the shut off valve, wiping it down with acetone to remove any water and then paint it with some vaseline to coat it with a moisture barrier. Those that have done this as a trial, did it work, those that have any other solutions, please chime in, those that have the same issue, what have you done or plan to do. None of my other shutoff valves seem to have been affected, more than likely as air circulation has been present for them. As always, your help is much appreciated.

BRONZE THRUHULL VALVES CORROSION

- Thread starter twodzusfittings

- Start date

Does it look similar to the well known green patina that copper develops? I used CLR to clean mine up. After soaking for a day or two all the patina was gone. The color was a bit more red and dull rather than the bright copper color I got when sanding the bottom. It also appeared to eat away the teflon tape

yes.Does it look similar to the well known green patina that copper develops?

A few articles I red said that these valves often times have a copper coating which explains the green patina we both saw. Vinegar and baking soda helped a little but the CLR got rid of 95% of it without scrubbing

Brass is not a good choice in a marine environment. This article from Sail magazine is worth the time to read:

www.sailmagazine.com

www.sailmagazine.com

--Peggie

Know how: Thru-hulls and Seacocks

Duncan Kent explains what you should look for in these vital fittings Clearly, with any device that penetrates the hull of a yacht, the choice of materials,

--Peggie

Bronze valves are generally tough units. The corrosion most often is a result of surface dripping.

First steps are inspection, cleaning, secure all hoses, check valve functioning, and monitor for leaks.

second phase. If leaks continue plan immediately to do replacement. Have plugs available to fill hole if valve comes apart.

Images from the outside can be deceiving.

First steps are inspection, cleaning, secure all hoses, check valve functioning, and monitor for leaks.

second phase. If leaks continue plan immediately to do replacement. Have plugs available to fill hole if valve comes apart.

Images from the outside can be deceiving.

Temporary Plug for Thru Hull Fitting

So, a friend bought a sailboat............without asking my opinion of it first. Let's be kind and say the boat needs, uh, work. Since this is a live-aboard, the first order of business is a working head. Installed now is your standard issue Jabesco and I will replace it with the same as well as...

forums.sailboatowners.com

Humidity type moisture should not be an issue with bronze. Constant dripping water or the like, would be.

Corrosion type bluish/green actually stops further corrosion , like a scab.

If you want to remove the corrosion, CLR it. Clean off all CLR. Then wipe on some machine oil with a rag. Repeat oiling often.

Jim...

Corrosion type bluish/green actually stops further corrosion , like a scab.

If you want to remove the corrosion, CLR it. Clean off all CLR. Then wipe on some machine oil with a rag. Repeat oiling often.

Jim...

I've never heard of oiling the surfaces on bronze valves, strainers or other. I wouldn't do it as it will then just attract dirt and look like a dirty mess.

Is oiling to prevent surface corrosion a thing?

When I clean my bronze strainer or do something else that allows salt water to come into contact with engine or other parts I rinse with fresh water, wipe dry or start the engine to allow heat drying.

Is oiling to prevent surface corrosion a thing?

When I clean my bronze strainer or do something else that allows salt water to come into contact with engine or other parts I rinse with fresh water, wipe dry or start the engine to allow heat drying.

Not True. I just told you.I've never heard of oiling the surfaces on bronze valves

The wiping on of a tiny amount of oil is better than the Vaseline.

I would not oil mine either, but they were chatting about moisture preventative.

Jim...

Yes!Is oiling to prevent surface corrosion a thing?

My Dad made me clean every Iron based tool and then wipe it with oily rag. [not so much on bronze]

Jim..

Yep, I do wipe my tools with a lightly oiled rag kept for the purpose, both on the boat and at home when I kept them in the basement. The difference is they are kept in clean containers.Yes!

My Dad made me clean every Iron based tool and then wipe it with oily rag. [not so much on bronze]

Jim..

Thanks

Ward

Corrosion Block by Lear Chemicals is the right product for this and it's not greasy to attract dirt.

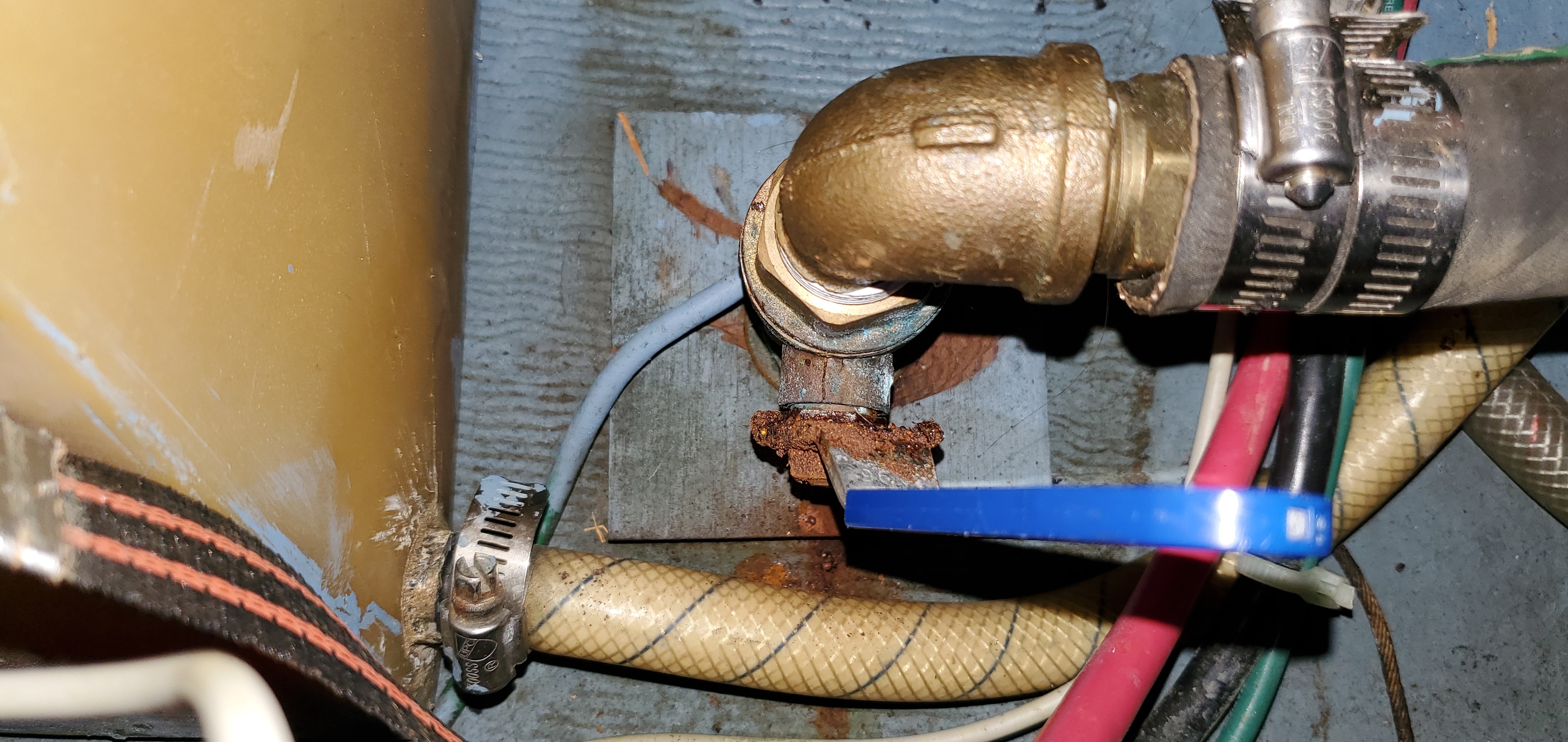

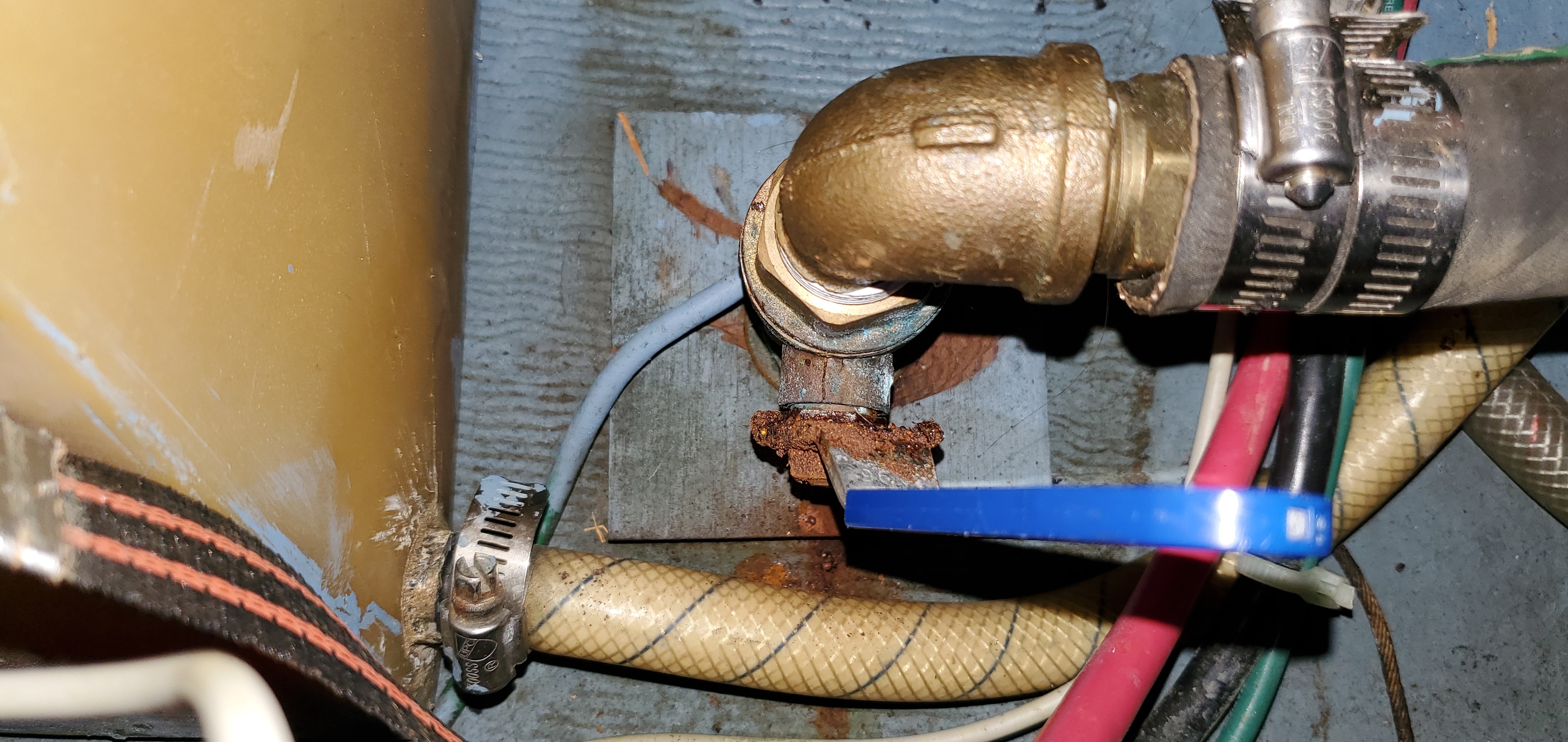

With the boats coming out of Winter Hibernation it's time to inspect the valves CLOSELY. While the valve functioned fine and the rusty handle on this bronze valve is eye catching (and can be replaced with stainless), it is distracting your eye from the crack created by ice forming in the valve.

Antifreeze had been poured in the sink when winterized, but there probably was already standing water at the closed valve.

This thru-hull moved slightly with a little pressure because the wood block had rotted.

The wood blocks are all being replaced with composite that will never rot. There are major delays right now on GROCO backing plates due to the international supply chain issues and I'm cheap so I get COOSA board (or G10) cut-off scraps for free (I always offer to pay) from a yard that work on large yachts. Both can be found on Amazon and fLeaBay but they are expensive. Grainger offers something similar.

Antifreeze had been poured in the sink when winterized, but there probably was already standing water at the closed valve.

This thru-hull moved slightly with a little pressure because the wood block had rotted.

The wood blocks are all being replaced with composite that will never rot. There are major delays right now on GROCO backing plates due to the international supply chain issues and I'm cheap so I get COOSA board (or G10) cut-off scraps for free (I always offer to pay) from a yard that work on large yachts. Both can be found on Amazon and fLeaBay but they are expensive. Grainger offers something similar.

That looks like a crack beside your blade in the 2nd pic. If it is you need to replace it.

The thru hull should be long enough to have 2 hose clamps. Where I am that will fail a survey and the insurance company won't cover until fixed.

I've been using Trudsign composite thru hulls and valves for 9 years. Never corrode, never stick and don't need maintenance.

The thru hull should be long enough to have 2 hose clamps. Where I am that will fail a survey and the insurance company won't cover until fixed.

I've been using Trudsign composite thru hulls and valves for 9 years. Never corrode, never stick and don't need maintenance.

What the blade was pointing to was the whole point of the picture, as stated in the text.That looks like a crack beside your blade in the 2nd pic. If it is you need to replace it. ...

Look again and you will see that is just an electrical ground connection. As seen in the first photo the hose connections were double clamped.The thru hull should be long enough to have 2 hose clamps. Where I am that will fail a survey and the insurance company won't cover until fixed....

Even though you probably know this too, composite thru-hulls do need maintenance with regular cycling and occasional lube, such as Marelube.

Ah yes I see the wire.

Trudesign are not the same as Marelon. They don't need any exercise or lubrication.

When I bought my boat it had a combination of Marelon and bronze. The bronze were suspect and the Marelon seized.

With the Trudesign it is one less thing to worry about.

Trudesign are not the same as Marelon. They don't need any exercise or lubrication.

When I bought my boat it had a combination of Marelon and bronze. The bronze were suspect and the Marelon seized.

With the Trudesign it is one less thing to worry about.