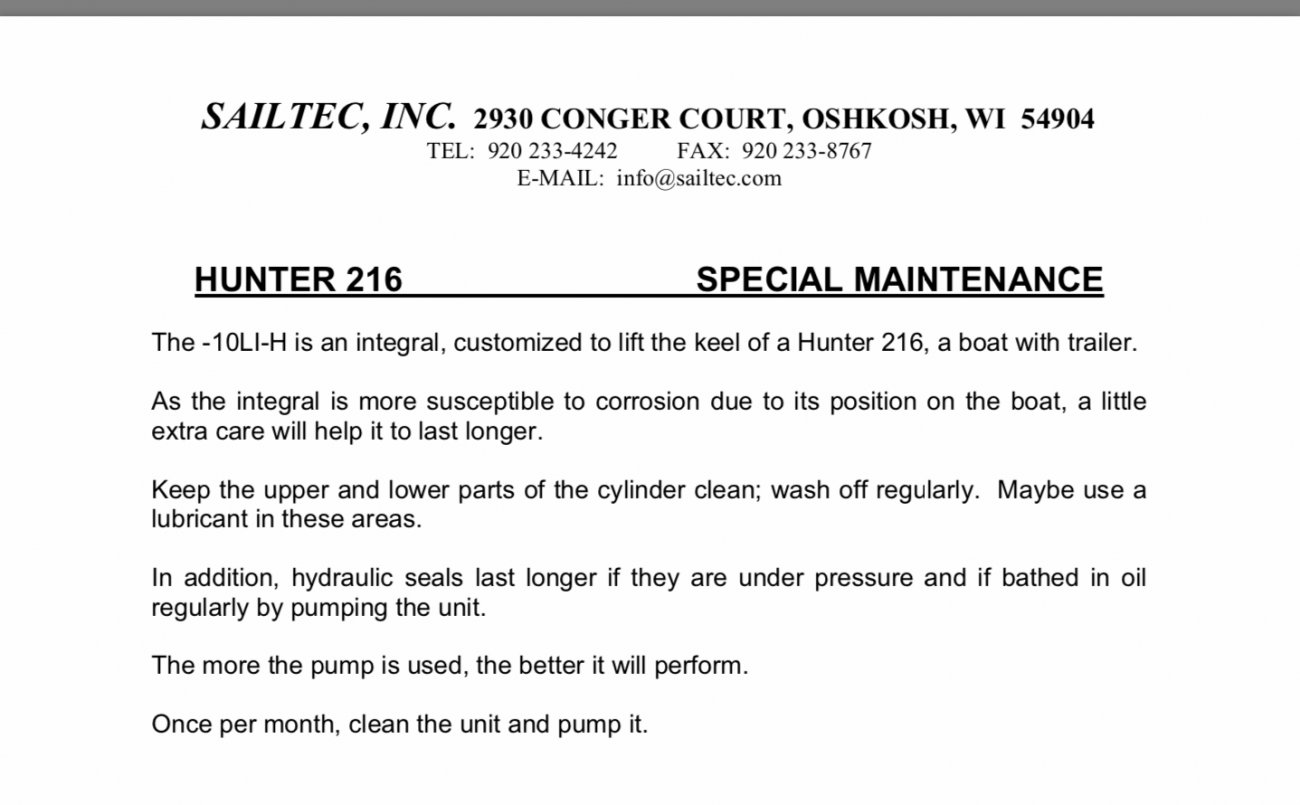

Dave, please clarify - by bow do you mean the end that attaches to the cable? Sailtec told me that they should be stored pump base down...

Within the Boat Info - download section of this site there are several manuals on the Sailtec ram that might help. The link below should take you to that section.Hi, anyone had problems with the Sailtec 'integral' hydraulic ram for the keel? I have now had two in just 4 years and at £800 (UK money) they are a bit costly. Is there an alternative?

Based on your post it would seem that you are on your third unit if you have purchased two in 4 years. I purchased a 2004 and it still has its original so your failure rate would indicate that the theory of air-lock due to storage might be the issue. @chuckwayne is correct in how the unit should be stored.

https://hunter.sailboatowners.com/dl/downloads.php?task=model&mid=68&model=216

Dave, this is from the Sailtec manualI don't know of an alternative, but it is important that they be stored with the bow down.

Hunter props, shafts, struts, and cutless bearingsAnd now a word from the sponsor...

See the product

When I had mine, I went through the airlock diagnosis that @Hunter216 described, and contacted the factory tech support, which was really helpful. I tried bleeding, adding oil, etc. without joy. I returned it to the factory (Minnesota, USA?) for a $600 rebuild plus shipping, which they said was needed every 10 years, or so. Personally, $60 a year is not that big a cost, but more frequent is questionable.

DaveI will check with SailTech, but I always thought they meant the bow of the boat down.

I wasn’t clear about this either until @chuckwayne set me right. If you think about it maybe there should be a big sticker on the ram and/or the cover for the centreboard enclosure to help clarify.. I can’t see a reason to store boat bow down other than maybe strong wind lifting it. Stern down would make sense from a drainage perspective. I’m guessing most would just park the trailer and not think about it.

I was looking at the 212 manual and noticed the multi sheave system to deal with its centreboard and wondered if that could somehow be used to replace the 216’s ram. Any idea of how much weight the 212’s system can handle?

Wow, that is one complicated tackle set! Maybe crazy Dave knows, but I wonder if they went to the hydraulic lift because 212 owners found the tackle to hard to use

Yes you would want to have lots of coffee in you before replacing the line on that one. However with modern blocks and synthetic line you could probably rig something that was small scale that might fit under the floor cover.Wow, that is one complicated tackle set! Maybe crazy Dave knows, but I wonder if they went to the hydraulic lift because 212 owners found the tackle to hard to use

I did a little measuring of the 216 centreboard mechanism today and determined that the cable eye that attached to the end of the ram moves about 12” as you raise/lower the board.

The fully retracted ram (centreboard raised) is about 22” long. This would be the available space for all the pulleys to work in.

It’s my understanding that the 216 board is about 500lbs and the 212 board is 150lbs. The 212 board is longer however and I don’t know where the attachment and rotation points are for it.

The centreboard system on the 212 is pretty complex but I think the mechanical advantage of all the pulleys is 9 or 10 if you didn’t use the one labeled 5 in the diagram and just connected the cable eye to the becket of the 4 block labeled 7.

I’m not sure of the math but I think that would make the 500lbs “feel” like 50lbs.

If that’s accurate it sounds feasible to use this kind of setup to replace the Sailtec unit.

Mount a couple of double blocks at the aft end of the slot, make some kind of slider car that would allow the 4 block to move back and forth without jamming in the slot and you have a viable alternative to the ram.

@JimInPB Can you comment on how much effort is required to move the board on the 212?

The fully retracted ram (centreboard raised) is about 22” long. This would be the available space for all the pulleys to work in.

It’s my understanding that the 216 board is about 500lbs and the 212 board is 150lbs. The 212 board is longer however and I don’t know where the attachment and rotation points are for it.

The centreboard system on the 212 is pretty complex but I think the mechanical advantage of all the pulleys is 9 or 10 if you didn’t use the one labeled 5 in the diagram and just connected the cable eye to the becket of the 4 block labeled 7.

I’m not sure of the math but I think that would make the 500lbs “feel” like 50lbs.

If that’s accurate it sounds feasible to use this kind of setup to replace the Sailtec unit.

Mount a couple of double blocks at the aft end of the slot, make some kind of slider car that would allow the 4 block to move back and forth without jamming in the slot and you have a viable alternative to the ram.

@JimInPB Can you comment on how much effort is required to move the board on the 212?

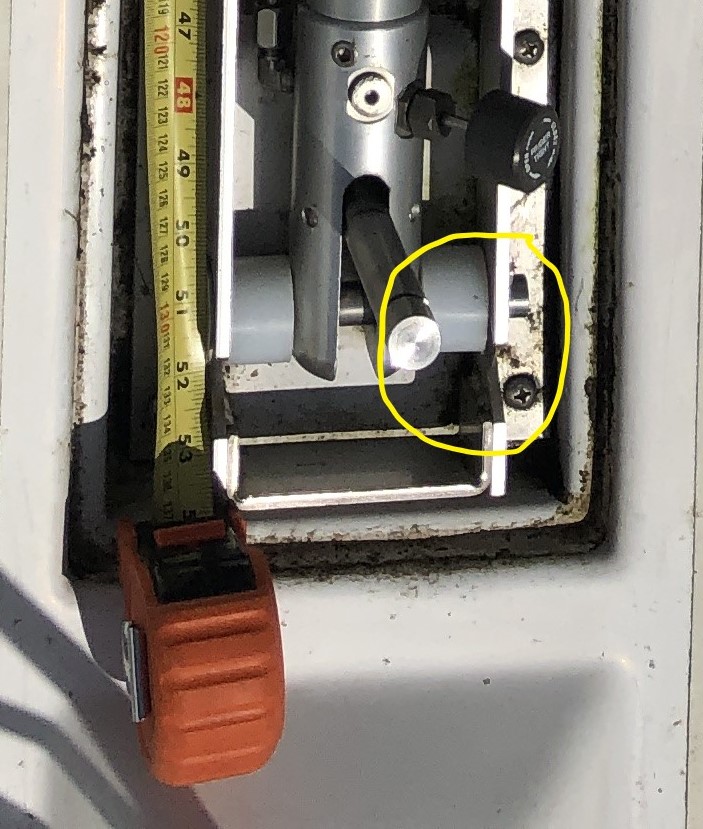

Some photos to clarify the concept.

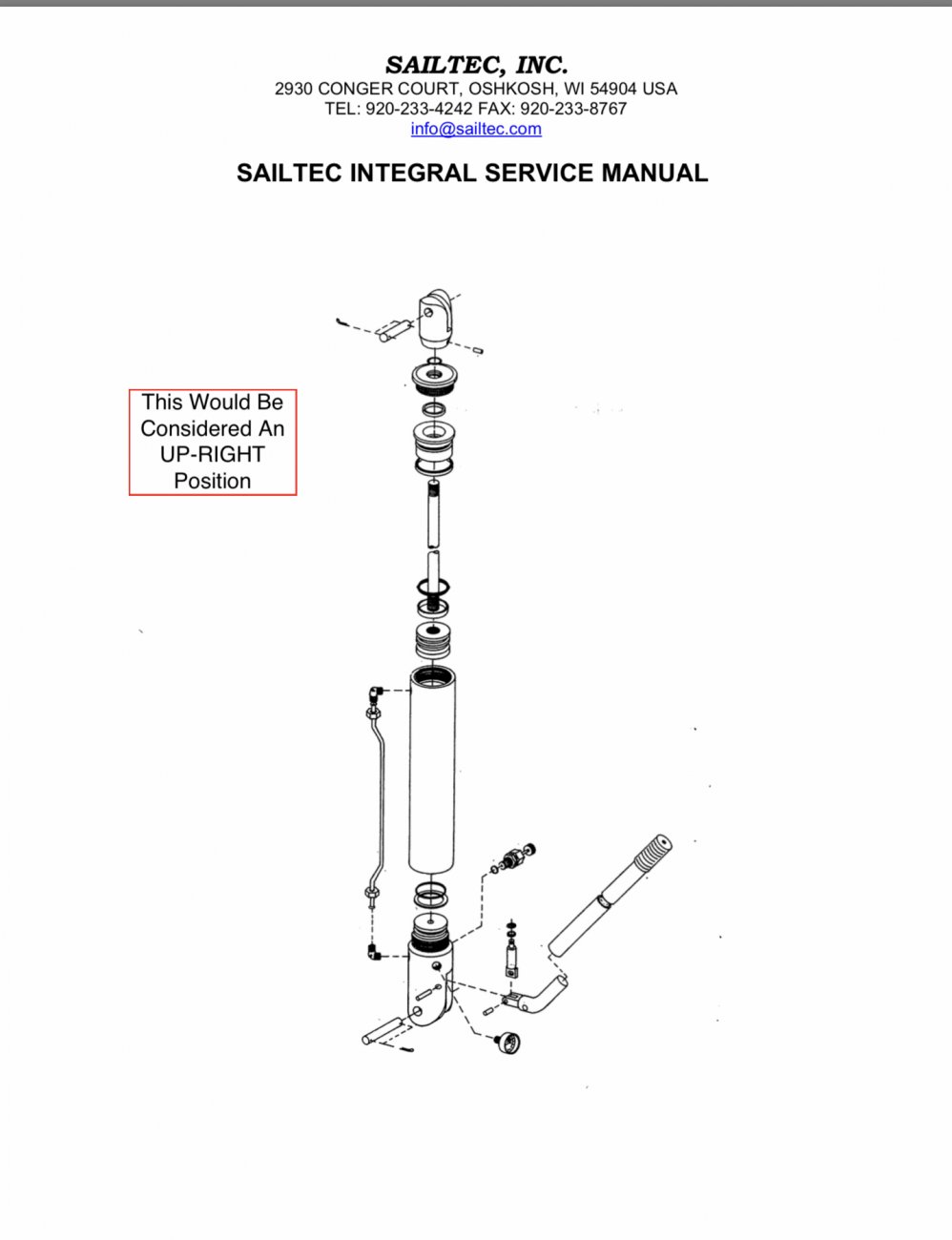

This shows the entire centreboard system on my 2004 Hunter 216. All of the mechanics fit into what appears to be a stainless framework about 54" in length and ~6-7 " wide (I didn't actual measure width). The "rails" of the system where the ram base and forward lift cable idler pulley are about 4" wide.

This photo is the ram base, it has a pin that fits down into a forward angled "slot" in the "rail". This is where the pair of 2 block pulleys would mount. Might have to fabricate something like a pin with a couple of shackles to hold the 2 sheave pulleys. Maybe a keeper to make sure the pin didn't pop loose somehow.

This photo shows the "rails" of the system ( tried to highlight them in yellow). Fabricate (maybe out of Delrin or similar) a "car" that would ride on the rails - maybe two dado slots to keep it tracking . The 4 sheave pulley that would connect to the existing eye in the end of the lift cable would mount on the "car" to prevent it from binding in the slot as it moves back and forth. Add in whatever rope guides, and cleats to the metal framework so no stress added to the hull material. Given the OP said he spent 1,600 UK (~$2000 USA) and has NO confidence that the Sailtec device will work when he needs it to it might be worth a shot.

This shows the entire centreboard system on my 2004 Hunter 216. All of the mechanics fit into what appears to be a stainless framework about 54" in length and ~6-7 " wide (I didn't actual measure width). The "rails" of the system where the ram base and forward lift cable idler pulley are about 4" wide.

This photo is the ram base, it has a pin that fits down into a forward angled "slot" in the "rail". This is where the pair of 2 block pulleys would mount. Might have to fabricate something like a pin with a couple of shackles to hold the 2 sheave pulleys. Maybe a keeper to make sure the pin didn't pop loose somehow.

This photo shows the "rails" of the system ( tried to highlight them in yellow). Fabricate (maybe out of Delrin or similar) a "car" that would ride on the rails - maybe two dado slots to keep it tracking . The 4 sheave pulley that would connect to the existing eye in the end of the lift cable would mount on the "car" to prevent it from binding in the slot as it moves back and forth. Add in whatever rope guides, and cleats to the metal framework so no stress added to the hull material. Given the OP said he spent 1,600 UK (~$2000 USA) and has NO confidence that the Sailtec device will work when he needs it to it might be worth a shot.

It requires some effort. My luggage scale read around 55-60# when the hook on it straightened out & let loose. The snap back broke the needle off the scale, so there will be no more measurements today.

This was with the board almost all the way up, and the boat is on the trailer now, so there is no water to support the board. This is probably a worst case scenario.

Didn’t intend for you to risk bodily injury and/or wreck your stuffIt requires some effort. My luggage scale read around 55-60# when the hook on it straightened out & let loose. The snap back broke the needle off the scale, so there will be no more measurements today.

This was with the board almost all the way up, and the boat is on the trailer now, so there is no water to support the board. This is probably a worst case scenario.

Seriously thanks for the effort.

I’m not sure this whole idea has any value other than a personal mental exercise. The OP seems to have vanished but I suppose if my Sailtec fails I would spend some $ on some blocks to see if I could make it work. I think maybe these would work

https://www.harken.com/productcategory.aspx?taxid=417

I raise the board on the 216 after each sail as I have it on a mooring. If I don’t the board slops around in the slot a little and would likely cause trouble. I’ve noticed that the last 1/3 of the pumps on the handle of the Sailtec take more effort than the early ones so I agree the amount of “work- load” the pulley(s) undergo is not constant as the board gets raised ie different than raising several hundred pounds straight up. I can see on the 216 the board pivots on a pin but the actual cable attachment point is several inches down the board. As the board raises the cable around the idler wheel changes angle and when it’s near the top of the raise is almost pulling the board in a linear forward direction.

Just found this info on the Sailtec website. SBO store sells a new one for $1,795.

https://www.sailtec.com/knowledge-base/knowledge-base

https://www.sailtec.com/knowledge-base/knowledge-base