I'm sure this has been beaten to death, and I've already had the lectures from others "never use plastic anything or you'll die!".

My 87 MkII has all maralon through hull fittings and what appears to be Forespar 850 series ball valves.

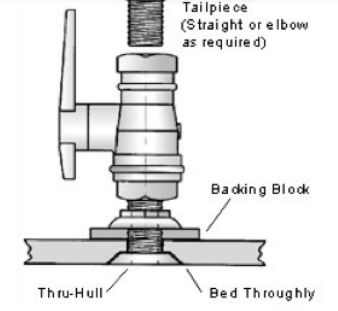

I'm guessing the thru-hulls are original looking at them. I suppose the ball valves could be original too. What I've noticed is that most of my thru's and valves look like this:

From the research I've done, it looks like like most of that is typical except for the missing backing plate? And I've noticed that this one in the picture is upsidedown, but not sure that matters much in this situation.

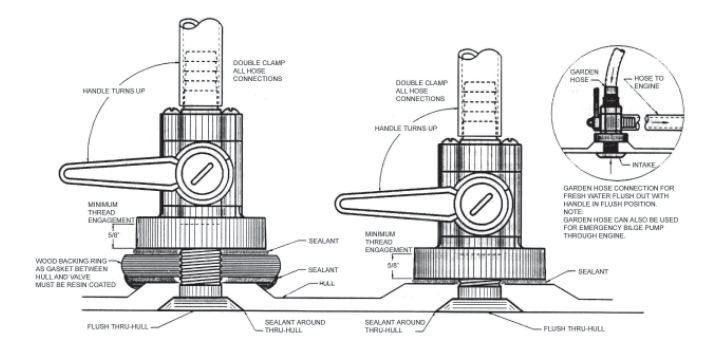

This is Forespar's instructions:

Since all of mine are very likely the original ones, I should probably change them, even if they appear to be working. Opinions?

Next, for same the price of the same maralon thru hull and same ball valve, it's almost a no-brainer to use the newer 93 series since the cost is so close anyway.

Lastly, what about the backing plates? Why don't I see any backing plates? Was this normal on Catalinas? are they just glassed in and it's okay to use without? The instructions for the 93 series say they require a large flat surface and always recommend backing plates. Do we need extra backing plates? Has anyone installed these 93's on their 30 and have pics?

Open to opinions/advice/discussions or even links to previously discussed info.

Thanks!

My 87 MkII has all maralon through hull fittings and what appears to be Forespar 850 series ball valves.

I'm guessing the thru-hulls are original looking at them. I suppose the ball valves could be original too. What I've noticed is that most of my thru's and valves look like this:

From the research I've done, it looks like like most of that is typical except for the missing backing plate? And I've noticed that this one in the picture is upsidedown, but not sure that matters much in this situation.

This is Forespar's instructions:

Since all of mine are very likely the original ones, I should probably change them, even if they appear to be working. Opinions?

Next, for same the price of the same maralon thru hull and same ball valve, it's almost a no-brainer to use the newer 93 series since the cost is so close anyway.

Lastly, what about the backing plates? Why don't I see any backing plates? Was this normal on Catalinas? are they just glassed in and it's okay to use without? The instructions for the 93 series say they require a large flat surface and always recommend backing plates. Do we need extra backing plates? Has anyone installed these 93's on their 30 and have pics?

Open to opinions/advice/discussions or even links to previously discussed info.

Thanks!