I get asked quite a bit how I label my wires and finally got around to an answer that was prompted by a post on this site a few days ago. I did not always use this technique and over the years have tried lots of "solutions" before settling on a solution that both works for me and tends to last in the marine environment....

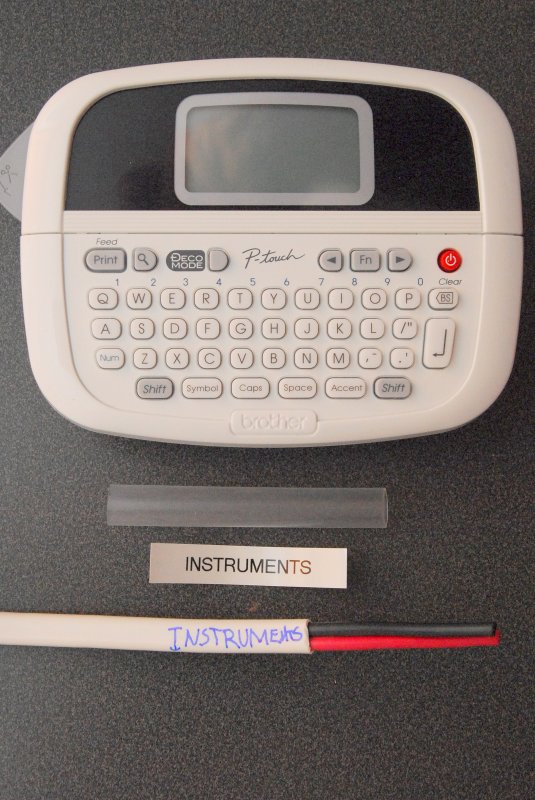

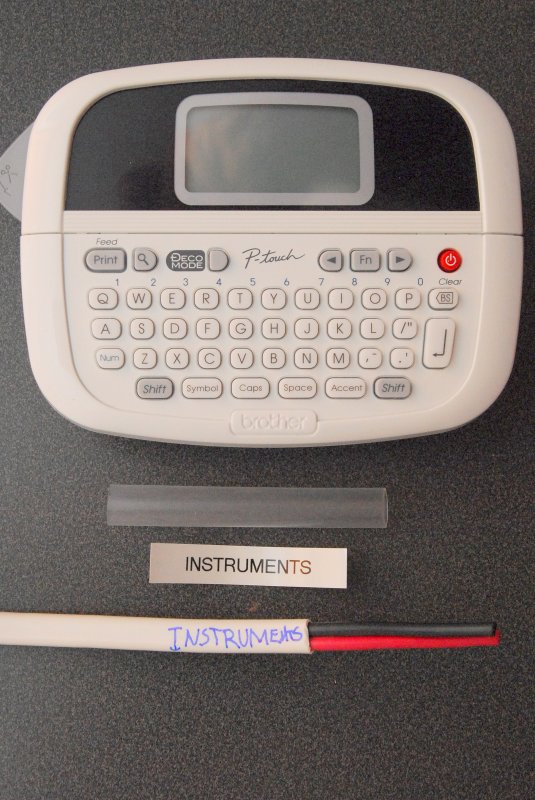

For me I have found that a simple Brother P-Touch label maker from Staples works wonders. These label makers often go on-sale for $9.99 to $20.00. Even for the one pictured I paid just $19.99 plus the TZ tape. Using a P-Touch is not however without some tricks and techniques, which I will explain.

In order to use a Brother P-Touch you will want to invest in their TZ label tapes shown in this photo. they come in many colors but black letters on white tape seems to work best. These tapes do not turn black when you heat shrink over them like the cheaper Brother tapes do. The cheaper labels will turn black once you hit them with a heat gun but the TZ labels survive, provided you don't go over the top with your heat gun....

Brother P-Touch & TZ Labels

For smaller individual wires, 16GA to 10GA, I also use the IDEAL #44-103 1 - 45 number kit. These are a cloth tape numbering system that only require one piece of "tape" rather than making your own double digit numbers with a 1- 9 numeric kit. They are also available in higher numbers if you need them.

I buy the IDEAL #44-103 at Home Depot. They are quite inexpensive and a single book will last you multiple wiring jobs.

IDEAL 1 - 45 Cloth Tape Wire Numbers

This is what each page of the #44-103 booklet looks like. There are 3 identical numbers on each short piece of tape so that the wires number is viewable from nearly 360 degrees around the wire. Each page also contains a few "single" numbers...

The Numbers

The TZ tapes also fit in the least expensive Brother P-Touch. This one cost me $9.99 at Staples..

For marking the wire, usually in duplex, triplex and larger battery cable I will often write on the jacket with a Sharpie marker first. This is a back up to the actual label..

As can be seen here I have labeled the wire with the Sharpie, made the P-Touch label and cut the clear heat shrink.

Brother P-Touch Small Version

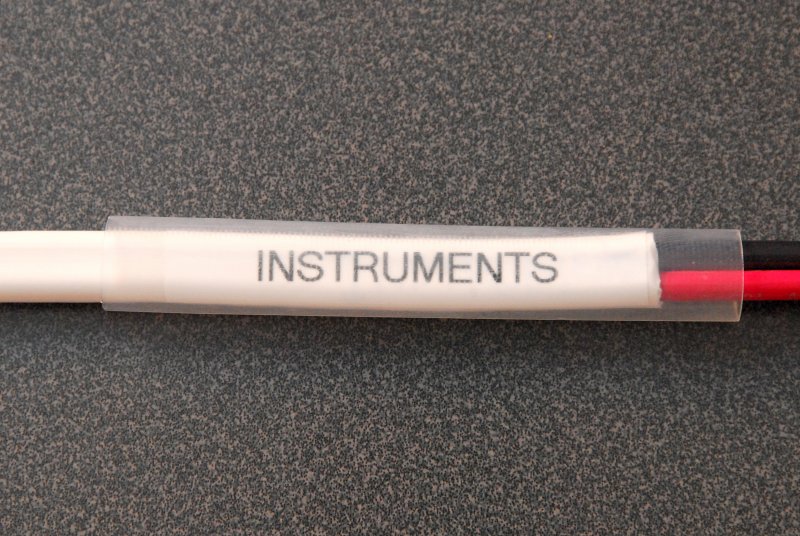

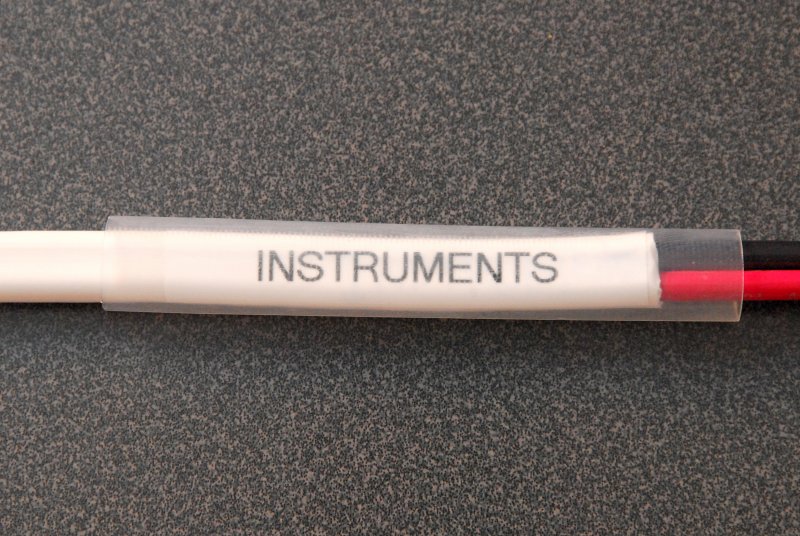

Here the P-Touch TZ label has been applied over the Sharpie writing.

Labeling Wires

Now I slide on some clear heat shrink tubing that has been cut a tad longer than the P-Touch label.

Labeled Before Shrinking

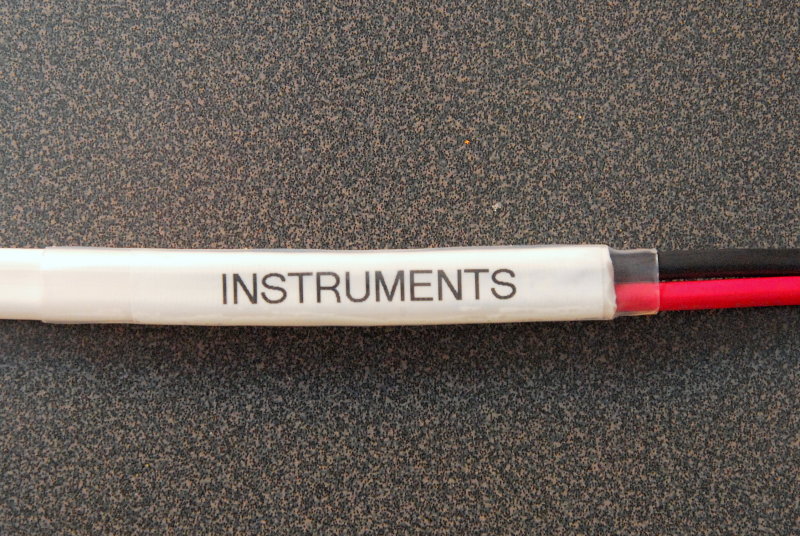

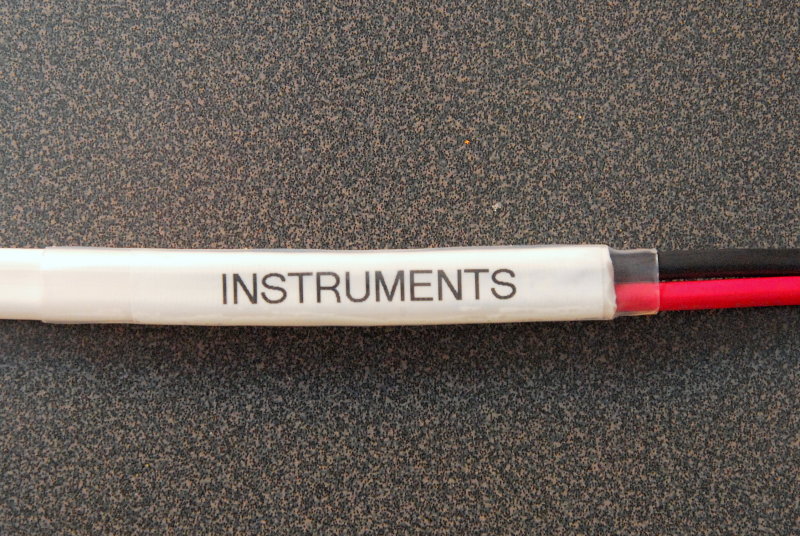

The last step is to shrink the clear tubing with a heat gun. DO NOT over heat it as this is not necessary just shrink it until it is tight. I find for duplex wire in 12GA and 14GA I use 1/2" clear shrink (NOT ADHESIVE LINED). For larger battery cables I use 3/4" to 1"...

The application of the clear heat shrink over the label creates a label that is robust enough to survive in the marine environment. It is one of the only methods I have found that actually lasts. It takes a little more time to do but as you become proficient it moves along quickly.

Labeling Wire - Shrunk

Over time I have learned that my customers who are willing to pay for the labeling want, and prefer, the wires to be labeled in a "common sense" fashion. I try to label so that even a novice with boat electrics can understand it. This is not always easy but once you get a system it becomes easier.

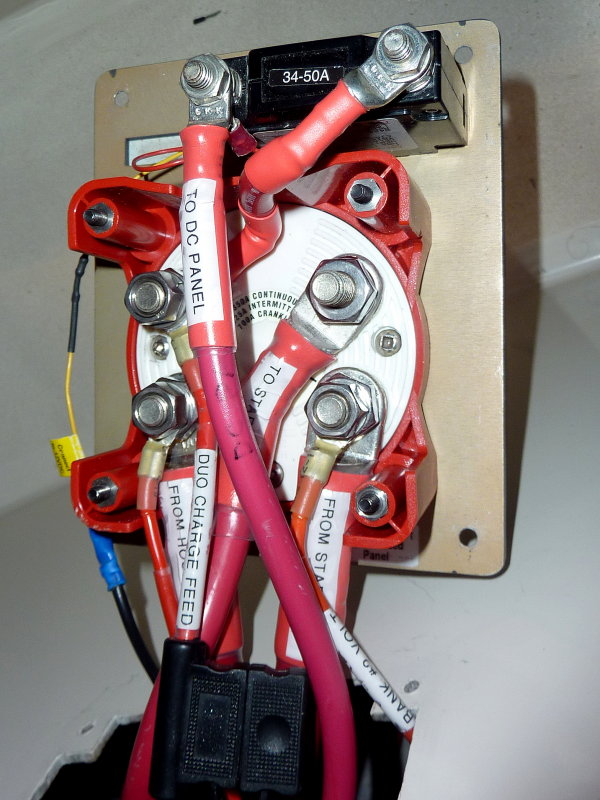

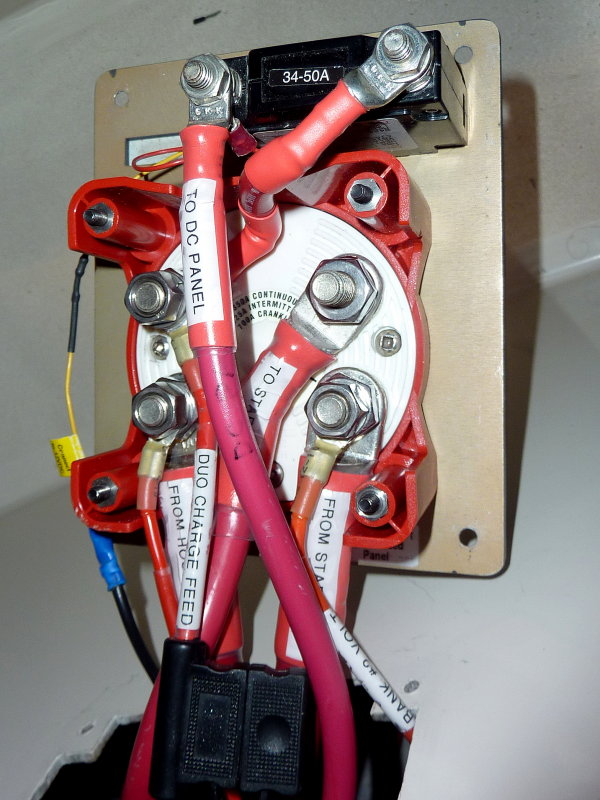

Common sense labeling on a boat means that each label is wired as "TO" or "FROM" and the device, load, panel, charger, panel etc. that corresponds with that wire...

In this photos you can see how easy it is to determine what goes where and what comes from where. If you needed to find the in-line fuse for the Duo Charger it would take two seconds to find.

For those of you that are marine electrical professionals this also makes over the phone trouble shooting considerably easier when your customer has an issue in a far and distant location from where you are. These little details go a long way towards your customers overall satisfaction with you and may turn into referrals! How many boaters know how to read a wiring diagram or even could locate it on the boat..?

I like "common sense" labeling where it is appropriate.

Back Side of A Battery Switch

Even on a small battery system labeling can make sense. This owner can disconnect and re-connect his system very easily and knows where every wire goes.. In this photo he has disconnected the banks for the winter, and removed any potential for parasitic loads, by removing the DC neg wires from the aft most battery...

Even if he forgot where the wires went, in the spring they are clearly labeled so reassembly is easy.

A Small Battery System

Earlier I mentioned the IDEAL number packs. In this picture I have labeled this wire #5. I have also cut a 1/2" length of 1/4" clear shrink.

Using The Ideal Numbers

When labeling individual wires be sure to place the number far enough down the wire so that when you strip & crimp on the terminal you have the space to do so. I usually crimp the terminal then slide the clear shrink back up the wire and melt both the terminals heat shrink and the number shrink together.

While the IDEAL numbers are fairly durable the addition of clear heat shrink takes it to the next level of durability. Durability with IDEAL numbers depends upon the location in the vessel.

Behind an AC/DC panel they survive pretty well but in a battery compartment or engine space not quite as well.. Just use your common sense as to when & where you'll want to use clear shrink over the number..

Some owners will be happy with just the stick on numbers and some are willing to go to the clear heat shrink step. As a DIY I'd suggest going over the IDEAL numbers with clear shrink as it costs pennies to do so.

Shrink & Done

Sometimes when I get a call to address sloppy wiring the poor owner barely stands a chance to even properly disconnect the 12V system for winter.

Note the P-Touch label about to fall off in this photo. This is why the clear heat shrink is key.. Do you know where any of these wires go? Neither did the owner....

Before

This is the same battery bank..... Much easier...

After

Like anything you can take your labeling to what ever level you want. This owner wanted the major neg wires labeled too and I had just completed that in this photo.....

Take It To Any level You Want

Good luck!!

For me I have found that a simple Brother P-Touch label maker from Staples works wonders. These label makers often go on-sale for $9.99 to $20.00. Even for the one pictured I paid just $19.99 plus the TZ tape. Using a P-Touch is not however without some tricks and techniques, which I will explain.

In order to use a Brother P-Touch you will want to invest in their TZ label tapes shown in this photo. they come in many colors but black letters on white tape seems to work best. These tapes do not turn black when you heat shrink over them like the cheaper Brother tapes do. The cheaper labels will turn black once you hit them with a heat gun but the TZ labels survive, provided you don't go over the top with your heat gun....

Brother P-Touch & TZ Labels

For smaller individual wires, 16GA to 10GA, I also use the IDEAL #44-103 1 - 45 number kit. These are a cloth tape numbering system that only require one piece of "tape" rather than making your own double digit numbers with a 1- 9 numeric kit. They are also available in higher numbers if you need them.

I buy the IDEAL #44-103 at Home Depot. They are quite inexpensive and a single book will last you multiple wiring jobs.

IDEAL 1 - 45 Cloth Tape Wire Numbers

This is what each page of the #44-103 booklet looks like. There are 3 identical numbers on each short piece of tape so that the wires number is viewable from nearly 360 degrees around the wire. Each page also contains a few "single" numbers...

The Numbers

The TZ tapes also fit in the least expensive Brother P-Touch. This one cost me $9.99 at Staples..

For marking the wire, usually in duplex, triplex and larger battery cable I will often write on the jacket with a Sharpie marker first. This is a back up to the actual label..

As can be seen here I have labeled the wire with the Sharpie, made the P-Touch label and cut the clear heat shrink.

Brother P-Touch Small Version

Here the P-Touch TZ label has been applied over the Sharpie writing.

Labeling Wires

Now I slide on some clear heat shrink tubing that has been cut a tad longer than the P-Touch label.

Labeled Before Shrinking

The last step is to shrink the clear tubing with a heat gun. DO NOT over heat it as this is not necessary just shrink it until it is tight. I find for duplex wire in 12GA and 14GA I use 1/2" clear shrink (NOT ADHESIVE LINED). For larger battery cables I use 3/4" to 1"...

The application of the clear heat shrink over the label creates a label that is robust enough to survive in the marine environment. It is one of the only methods I have found that actually lasts. It takes a little more time to do but as you become proficient it moves along quickly.

Labeling Wire - Shrunk

Over time I have learned that my customers who are willing to pay for the labeling want, and prefer, the wires to be labeled in a "common sense" fashion. I try to label so that even a novice with boat electrics can understand it. This is not always easy but once you get a system it becomes easier.

Common sense labeling on a boat means that each label is wired as "TO" or "FROM" and the device, load, panel, charger, panel etc. that corresponds with that wire...

In this photos you can see how easy it is to determine what goes where and what comes from where. If you needed to find the in-line fuse for the Duo Charger it would take two seconds to find.

For those of you that are marine electrical professionals this also makes over the phone trouble shooting considerably easier when your customer has an issue in a far and distant location from where you are. These little details go a long way towards your customers overall satisfaction with you and may turn into referrals! How many boaters know how to read a wiring diagram or even could locate it on the boat..?

I like "common sense" labeling where it is appropriate.

Back Side of A Battery Switch

Even on a small battery system labeling can make sense. This owner can disconnect and re-connect his system very easily and knows where every wire goes.. In this photo he has disconnected the banks for the winter, and removed any potential for parasitic loads, by removing the DC neg wires from the aft most battery...

Even if he forgot where the wires went, in the spring they are clearly labeled so reassembly is easy.

A Small Battery System

Earlier I mentioned the IDEAL number packs. In this picture I have labeled this wire #5. I have also cut a 1/2" length of 1/4" clear shrink.

Using The Ideal Numbers

When labeling individual wires be sure to place the number far enough down the wire so that when you strip & crimp on the terminal you have the space to do so. I usually crimp the terminal then slide the clear shrink back up the wire and melt both the terminals heat shrink and the number shrink together.

While the IDEAL numbers are fairly durable the addition of clear heat shrink takes it to the next level of durability. Durability with IDEAL numbers depends upon the location in the vessel.

Behind an AC/DC panel they survive pretty well but in a battery compartment or engine space not quite as well.. Just use your common sense as to when & where you'll want to use clear shrink over the number..

Some owners will be happy with just the stick on numbers and some are willing to go to the clear heat shrink step. As a DIY I'd suggest going over the IDEAL numbers with clear shrink as it costs pennies to do so.

Shrink & Done

Sometimes when I get a call to address sloppy wiring the poor owner barely stands a chance to even properly disconnect the 12V system for winter.

Note the P-Touch label about to fall off in this photo. This is why the clear heat shrink is key.. Do you know where any of these wires go? Neither did the owner....

Before

This is the same battery bank..... Much easier...

After

Like anything you can take your labeling to what ever level you want. This owner wanted the major neg wires labeled too and I had just completed that in this photo.....

Take It To Any level You Want

Good luck!!