So as things go I have been putting off the complete re-wire of my boat due to the sheer time involved. I was planning on it last winter but I wound up doing the bottom job instead.

I have been running new wires, on an as needed basis, and replacing stuff that I knew was bad. Unfortunately boats are like the proverbial haystack and until you peel away all the hay, read interior cabinetry, headliner etc. etc., you never know what you will find. While much of the wiring is still on ok shape a lot leaves me scared, especially the AC side, which I had fortunately never used because, I knew it was bad..

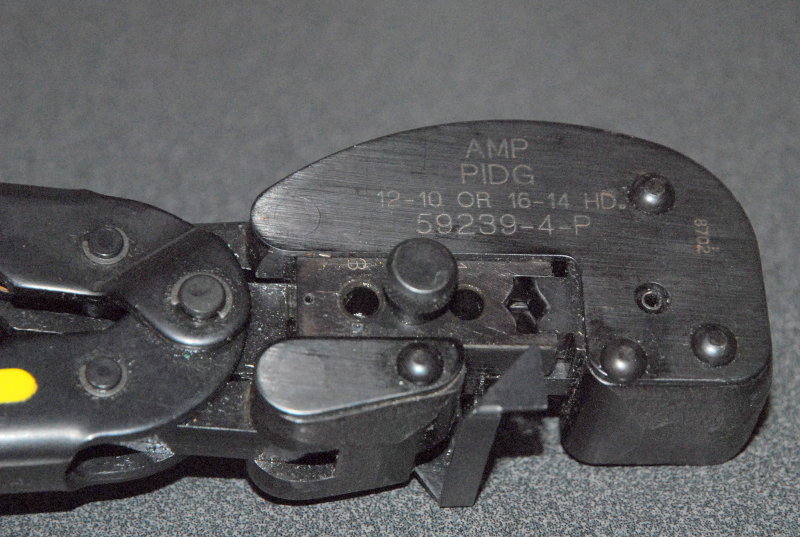

I found improper use of a dimple crimper, which really shouldn't be used on this type of connector to begin with but when you crimp it from the wrong side....well...

I sliced open the insulator and removed it. This is how the crimp executed. It's no wonder the wire simply slid out in my hand. This was done by the guy who installed the refrigeration!

This is solder creep. The PO installed a shunt and made this jumper. Not crimped, lots of solder creep and fractured wires.

This is why it is very, very important to properly size DC wiring and to ensure a good connection. This 16 ga wire fed a large vane type shower sump that was well beyond the capacity of the wire..

Never ceases to amaze me what you find on old boats, I'm sure I'll find more..

I have been running new wires, on an as needed basis, and replacing stuff that I knew was bad. Unfortunately boats are like the proverbial haystack and until you peel away all the hay, read interior cabinetry, headliner etc. etc., you never know what you will find. While much of the wiring is still on ok shape a lot leaves me scared, especially the AC side, which I had fortunately never used because, I knew it was bad..

I found improper use of a dimple crimper, which really shouldn't be used on this type of connector to begin with but when you crimp it from the wrong side....well...

I sliced open the insulator and removed it. This is how the crimp executed. It's no wonder the wire simply slid out in my hand. This was done by the guy who installed the refrigeration!

This is solder creep. The PO installed a shunt and made this jumper. Not crimped, lots of solder creep and fractured wires.

This is why it is very, very important to properly size DC wiring and to ensure a good connection. This 16 ga wire fed a large vane type shower sump that was well beyond the capacity of the wire..

Never ceases to amaze me what you find on old boats, I'm sure I'll find more..