Hi All,

As promised a loooooong time ago I am reporting on the use of Tef-Gel on the prop shaft coupling. After two+ years my coupling came off 100% rust free and with all the original tolerances intact and not destroyed by a thin layer of rust.

Prior to installation I coated the inside of the coupling, the key way, the key and the shaft with a liberal amount of Tef-Gel.. While most of it was wiped away by the very tight tolerances when assembling it the anti-corrosion abilities were unharmed. After removal both the shaft and inside of the coupling have a think feeling, extra tacky layer of protective Tef-Gel.

Mike the manager at my prop shop thought for sure the Tef-Gel would have been totally wiped away and would add noting but it survived. The nice thing about Tef-Gel is that unlike Anti-Seize products that contain graphite or metals it does not add to galvanic corrosion issues.. It also works very, very well as a rust inhibitor..

My coupling came off like it was new with NO penetrating oil and only two bolts with my gear/hub puller.

On my last boat, which was brand new, I ran it for less than three months then hauled to change to a PSS. In just three months of use the coupling was already rusted on!!

Tef-Gel works!!!

WARNING: It should be noted that any sort of lube is advised against in a straight coupling. I know this and still decided the risk was worth it on my own boat. I have seen no odd wear to my key or set screws BUT my coupling was PROFESSIONALLY fitted to a light press fit tolerance.

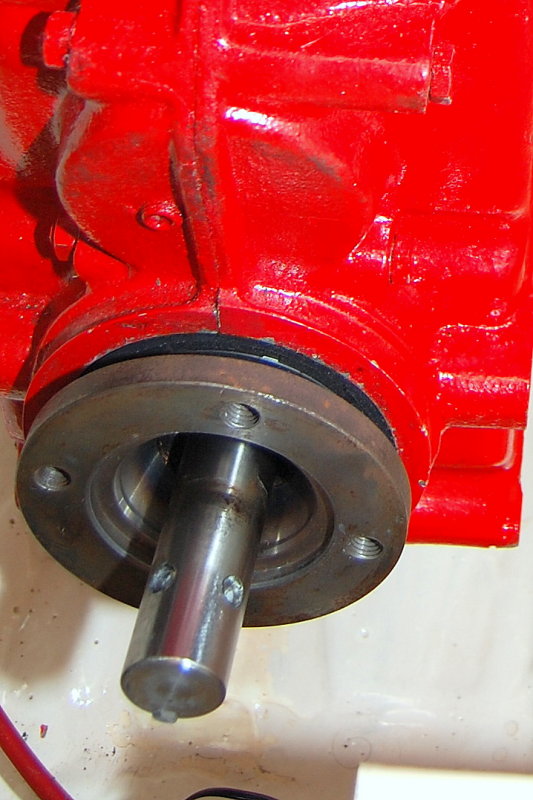

After two plus years it came right off:

No RUST!

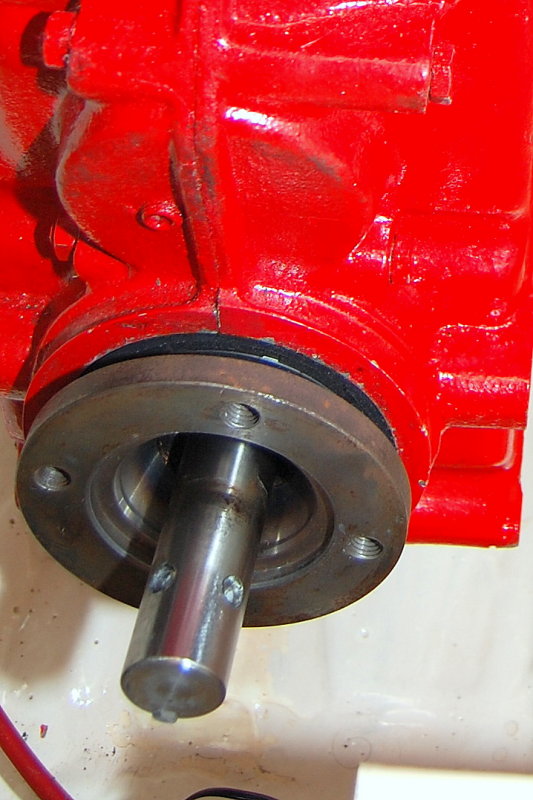

The Shaft:

Better Lighting Showing NO RUST!!

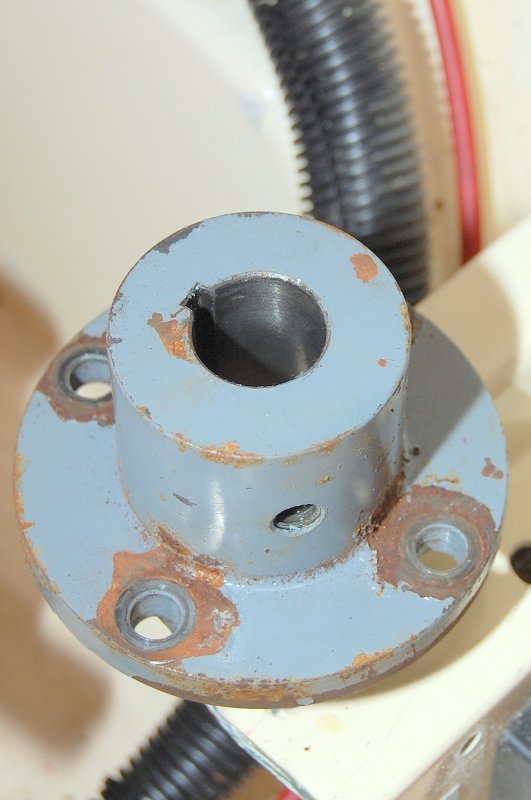

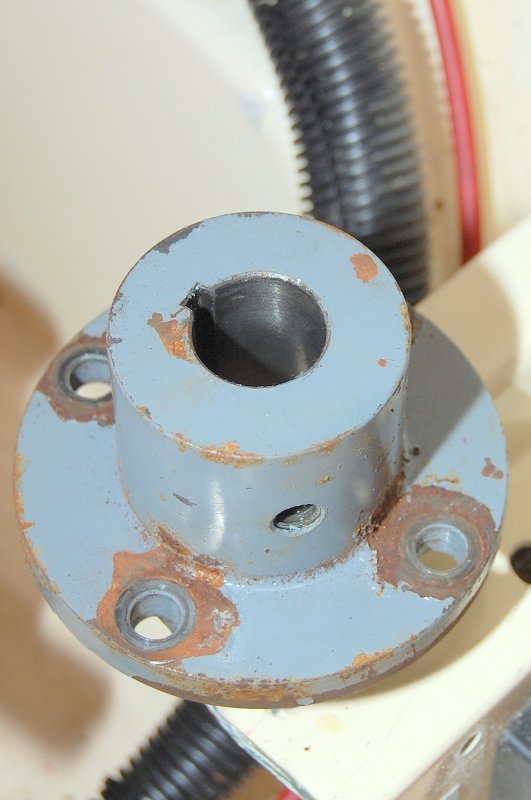

This photo shows NO Tef-Gel after just three months (note the rust adhered to the shaft that broke off the internal surface of the coupling):

__________________

As promised a loooooong time ago I am reporting on the use of Tef-Gel on the prop shaft coupling. After two+ years my coupling came off 100% rust free and with all the original tolerances intact and not destroyed by a thin layer of rust.

Prior to installation I coated the inside of the coupling, the key way, the key and the shaft with a liberal amount of Tef-Gel.. While most of it was wiped away by the very tight tolerances when assembling it the anti-corrosion abilities were unharmed. After removal both the shaft and inside of the coupling have a think feeling, extra tacky layer of protective Tef-Gel.

Mike the manager at my prop shop thought for sure the Tef-Gel would have been totally wiped away and would add noting but it survived. The nice thing about Tef-Gel is that unlike Anti-Seize products that contain graphite or metals it does not add to galvanic corrosion issues.. It also works very, very well as a rust inhibitor..

My coupling came off like it was new with NO penetrating oil and only two bolts with my gear/hub puller.

On my last boat, which was brand new, I ran it for less than three months then hauled to change to a PSS. In just three months of use the coupling was already rusted on!!

Tef-Gel works!!!

WARNING: It should be noted that any sort of lube is advised against in a straight coupling. I know this and still decided the risk was worth it on my own boat. I have seen no odd wear to my key or set screws BUT my coupling was PROFESSIONALLY fitted to a light press fit tolerance.

After two plus years it came right off:

No RUST!

The Shaft:

Better Lighting Showing NO RUST!!

This photo shows NO Tef-Gel after just three months (note the rust adhered to the shaft that broke off the internal surface of the coupling):

__________________