Dubo, did you ever get to the bottom of what it was? I just removed my heat exchanger from the engine, and when I opened the bottom cover, it was thick brown sludge and very greasey. I have very little experience, but my gut tells me this is oil, because it sure feels oily. Hoping it is not a sign of a head gasket. I have no issues with my engine, however, all my sensors never worked since I purchased this boat last year. I've got the whole thing sitting in evapo-rust so I can remove the copper part and clean everything. The tube is stuck in the exchanger. I pouned on it with a rubber mallet and it would not move. Hope I did not break it.That's an interesting thought. My first guess was rust. Is there a way to determine if it is oil? Scoop some out and put in clean water and see reaction? Feel for oily texture, though AF is oily too? Lab test it? Oil inspection shows no water mixing in.

Removing sludge from heat exchanger-Yanmar

- Thread starter Dubo

- Start date

If it disperses in tap water, there is no oil present regardless of how it feels in the concentrated film.it was thick brown sludge and very greasey.

What copper part ? Even more important what engine ?I've got the whole thing sitting in evapo-rust so I can remove the copper part and clean everything.

What tube ?The tube is stuck in the exchanger.

What, what, what ? ? ? ? Please post a picture of what you have and what's going on.I pouned on it with a rubber mallet and it would not move.

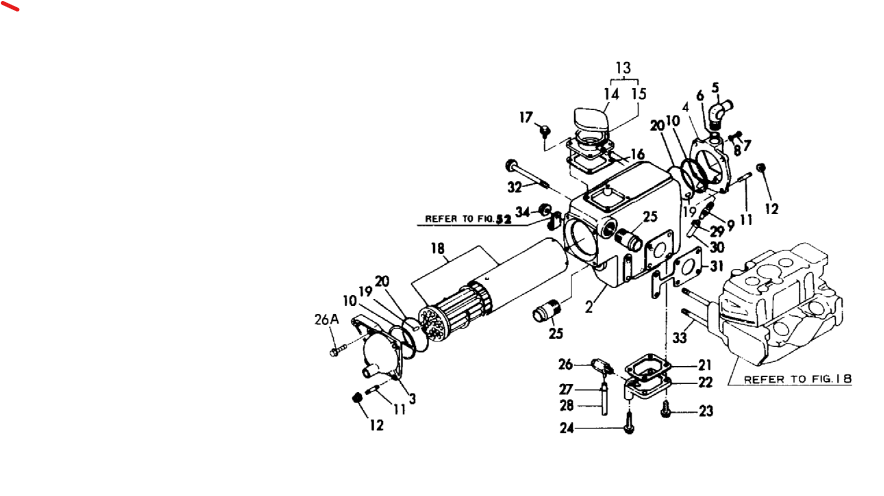

I have a Yanmar 2GM20F and I removed the heat exchanger to clean it, because I could tell it was a mess inside. I will try to disperse the sludge in tap water if I still have some of it. I attached a photo of the heat exchanger. Part 18 is the tube that is stuck in the exchanger. It should slide out, but it is stuck at the moment.

Have you removed the rear head yet ? After 24 years in place, I had mine apart for cleaning recently and everything came apart without any resistance. There's nothing in there for it to catch on.Part 18 is the tube that is stuck in the exchanger.

The interior of the tubes (raw water side) can be nicely cleaned with a .22 rifle barrel brush. The outside of the tubes can only be cleaned by flushing the engine with a cleaner. Sorry I don't have a name for a cleaner but if I were looking at cleaning my AF cooling system, I'd look at Prestone cleaner :

They make the antifreeze I buy so they should know what they're doing when it comes to a cleaner. I hope.

Be sure to coat the two large "O" rings at the HE heads with a non-petroleum grease (such as SuperLube) when assembling the heat exchanger. It helps them to seat in the correct location. Do not coat the interior gaskets or they'll slide around and possibly be in the wrong location when the head tightens.

After cleaning out your cooling system, when you finally fill your system with a 50/50 antifreeze mix, be sure to use only distilled water (from a drug store) to add to the concentrated antifreeze. No tap water. I'm pretty sure you're presently looking at precipitates from your tap water. the sludge feels greasy because the particles of precipitated minerals are microscopic in size.

Let us know how the HE removal goes.

Yes, I removed both sides. I actually removed the entire cast iron unit (item 2) by unbolting it from the engine because it looked awful inside from the top opening. The copper tube is really stuck. When I unbolted item 22, the bottom cover, that is where most of the sludge was, although it is throughout. WHen I first opened the top to check the fluid level, I couldn't even see any coolant, so I was worried at first, but I was able to drain a lot of coolant out the bottom before I removed it all. All my sensors have never worked since I purchased the boat last year. I never noticed anything wrong with the engine. The entire reason I got into the heat exchanger is because I started disassembling the front of the engine to remove the gear timing cover to access a broken bolt that holds the raw water pump on. I am also in the process of doing that. I had all the pipes removed, so I figured what the heck.Have you removed the rear head yet ? After 24 years in place, I had mine apart for cleaning recently and everything came apart without any resistance. There's nothing in there for it to catch on.

Thanks for the tips on using the paste O rings and not on the interior gaskets. I bought some silicone paste for the O-rings. I do hope you are right about the sludge being just minerals. I plan on putting everything back together and maybe trying to do a pressure test on the freshwater system, filling it completely with distilled water first and starting it up. Then I will look for oil at the top. Then I will flush it again and put in the coolant.

Does your high temperature coolant alarm work ? Your high temp. coolant and low oil pressure alarms MUST work. May I advise you to not even look at your boat until you have those two alarms in place and working ? No oil press. alarm means your engine could be destroyed within seconds at high RPM if your oil pressure is ever lost. Just not worth it.All my sensors have never worked since I purchased the boat last year.

When I unbolted item 22, the bottom cover, that is where most of the sludge was, although it is throughout.

WHen I first opened the top to check the fluid level, I couldn't even see any coolant, so I was worried at first, but I was able to drain a lot of coolant out the bottom

This is not sounding any better. You may have been overheating your engine and not knowing it when you say you couldn't see water in the HE. I would strongly suggest looking into a chemical flush of your engine as it sounds as if it's been neglected badly by the PO. I would be worried about having channels in your block plugged off. This is also very bad for your engine. Contact Prestone and talk to them about cleaning your engine if you're in doubt.

Forgot to ask, have you been losing coolant recently and always adding AF to your system ? If you're not losing coolant on a continuous basis, it's doubtful your head gasket is leaking.Then I will look for oil at the top.

This may be the only way you're going to remove the tube bundle. Warm the Evaporust bath until a little more than skin temperature and it will work a little faster overnight. The corrosion products have cemented the bundle in place. What you need to break the cemented joint is very, very, very gentle taps with a small steel hammer around the circumference on both ends of the bundle. The steel hammer will impart sharp impacts but keep them as light as possible. If you make any marks on the bundle, you're hitting it much too hard. Don't rush it as this component is $ $ $ $ $ $.I've got the whole thing sitting in evapo-rust so I can remove the copper part and clean everything.

Keep us informed.

After several days of soaking the exchanger in evaporust, it still wouldn't budge. I cut out a circular piece of wood with a hole saw and removed some material around the center so it would fit over the end of the copper tubes. Then I pounded on it hard with a mallet hammer. I hope I did not damage it, but it seems ok. The outer covering is highly pitted, see photo. I'm hoping it doesn't make much difference and that the copper tubes are not damaged at the ends.

Instead of using that Prestone to flush the system, I might try just distilled water at first and see if any oil appears in the head exchanger. I think you are right and that there is no oil in the cooling system because the sludge did dissolve in water. I also am adding a coolant resevior and I replaced the tank cap so that everything will be air tight and it will be able to expand/contract. Previously I had a resevior but it was emtpy and melted because someone hung it too close to the exhuast elbow. The coolant could have been low because it had no sealed resevior. The top-inside of the cast iron exchanger was badly corroded, probably due to it not being full all the time.

Instead of using that Prestone to flush the system, I might try just distilled water at first and see if any oil appears in the head exchanger. I think you are right and that there is no oil in the cooling system because the sludge did dissolve in water. I also am adding a coolant resevior and I replaced the tank cap so that everything will be air tight and it will be able to expand/contract. Previously I had a resevior but it was emtpy and melted because someone hung it too close to the exhuast elbow. The coolant could have been low because it had no sealed resevior. The top-inside of the cast iron exchanger was badly corroded, probably due to it not being full all the time.

jssailem

SBO Weather and Forecasting Forum Jim & John

- Oct 22, 2014

- 23,789

With heat exchangers, the ends are designed to keep the water inside the unit. The sleeve is designed to keep the fluids inside the sleeve. With holes in the pitted surface, you have fluid leaking outside the sleeve and between the outer casing and the sleeve.The outer covering is highly pitted, see photo. I'm hoping it doesn't make much difference

I would expect the exchanger to leak fluids with the fluids under pressure, either raw cooling water or coolant from the enclosed system.

The extensive pitting is likely from galvanic corrosion over many years. Not sure if that particular engine uses sacrificial anodes to prevent that kind of damage. You could take it to a radiator shop to determine if the thru & thru pits could be welded: however, think it is time for a new heat exchanger.The top-inside of the cast iron exchanger was badly corroded, probably due to it not being full all the time.

I'm not sure the holes in the sleeve will make much difference because the coolant is on both sides. Perhaps a tad less efficient, but I don't see why it would matter. It doesn't seem like the sleeve was watertight to begin with because it slides between the ends a little. As long was copper tubes inside are not leaking, I should be good.With heat exchangers, the ends are designed to keep the water inside the unit. The sleeve is designed to keep the fluids inside the sleeve. With holes in the pitted surface, you have fluid leaking outside the sleeve and between the outer casing and the sleeve.

I would expect the exchanger to leak fluids with the fluids under pressure, either raw cooling water or coolant from the enclosed system.

The extensive pitting is likely from galvanic corrosion over many years.

Most likely from lack of shaft Zinc or Engine Zinc [If Yanmar has one]

Jim...

Your copper tubes don't look too bad but the SS jacket looks it's had the

beat out of it. We don't know the age of the engine so we don't know if that era used zincs. The GM engines and later don't use zincs. As far as keeping the sea water and AF coolant apart, you are right when you say the corrosion on the SS doesn't affect anything. If one is concerned about holes in the SS jacket, what about the 2" hole between your fingers ? You're relying on the big "O" rings at the tube sheets being crushed by the HX heads to do the sealing.

beat out of it. We don't know the age of the engine so we don't know if that era used zincs. The GM engines and later don't use zincs. As far as keeping the sea water and AF coolant apart, you are right when you say the corrosion on the SS doesn't affect anything. If one is concerned about holes in the SS jacket, what about the 2" hole between your fingers ? You're relying on the big "O" rings at the tube sheets being crushed by the HX heads to do the sealing.You may want an automotive shop to pressure test the bundle just to be sure. Once it's all together, you may want to get some salt test strips from Amazon to monitor your coolant.

Haha, exactly.View attachment 220771

If one is concerned about holes in the SS jacket, what about the 2" hole between your fingers ?

View attachment 220774

I was debating buying something to do a pressure test with, which would be nice, but I should be able to detect any leaks by just monitoring levels. If anyone has a pressure test kit that they recommend, let me know! The salt test strips are a good idea, except I am on a fresh water lake (Lake Norman, NC). I was surprised to see that on my model 2GM20F (1986), there are no zincs on the engine.

Sorry, forgot that "minor' detail.The salt test strips are a good idea, except I am on a fresh water lake (Lake Norman, NC).

I was not sure if the GM series eliminated the anodes any time during their production run.I was surprised to see that on my model 2GM20F (1986), there are no zincs on the engine.

Below is a good article from Torrenson on the evolution of Yanmar Engines.

Attachments

-

101 KB Views: 2,737