While digging around in some old boat parts boxes, I found the stuffing box from my old Catalina 36. It was sitting in the parts box because I had chosen to replace it with a PSS Shaft Seal to make my bilge totally dry. Today was a rainy Sunday and I though it would be a good time to rig it up in my barn and photograph how to replace the flax packing inside one of these "work horse" style stuffing boxes.

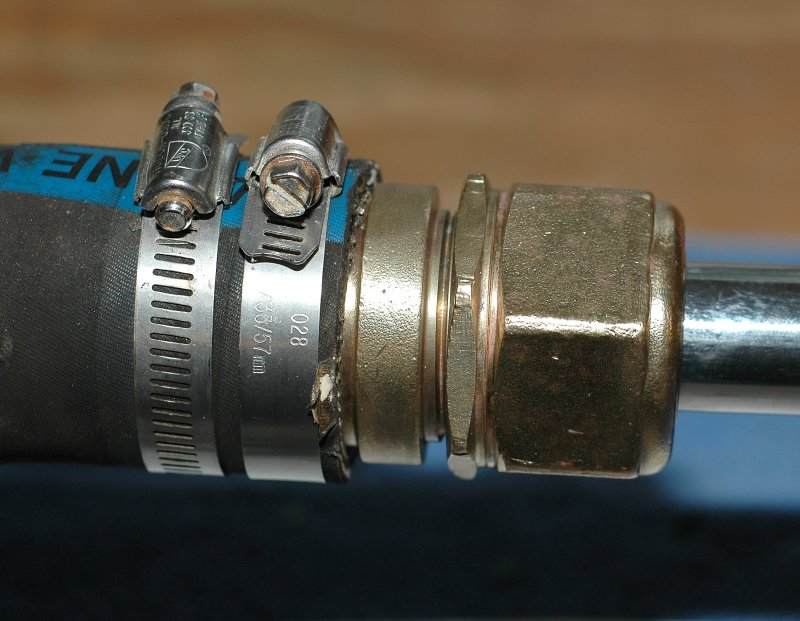

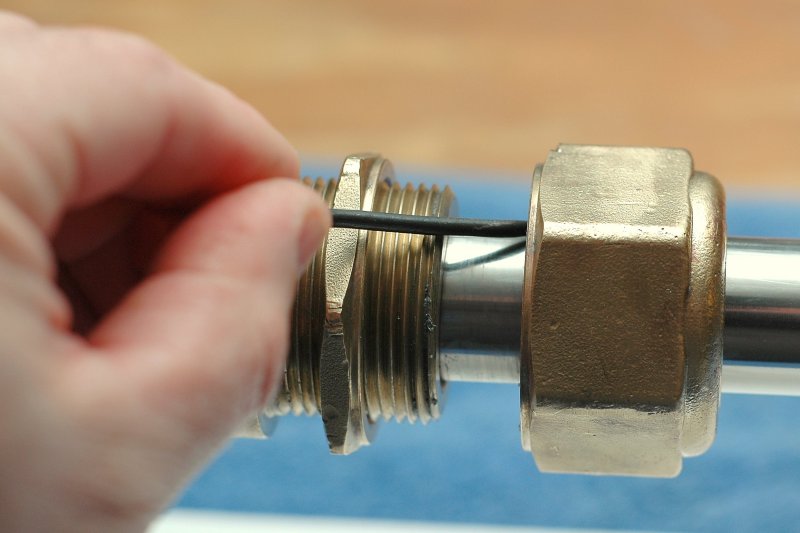

For illustrative purposes I cleaned the stuffing box of it's oxidation and grime with my drill press and a brass wire brush. I used a piece of 1" diameter stainless steel as my makeshift prop shaft to complete the picture and present this as it would look inside a boat.

In this picture what you are actually seeing are two nuts not one. The larger of the two is where the flax resides. The thin nut, on the left, is the locking nut. Once re-packed, & properly adjusted, you lock these nuts together with two large wrenches. If you don't lock these nuts down tight enough, meaning the nuts are each tightened in opposite directions against each other quite tightly, you run the risk of the big nut backing its self off the threads when you put the transmission in reverse. There have been more than a few boats sunk by improper tightening of the stuffing box nuts! Just ask the Boat US insurance division.

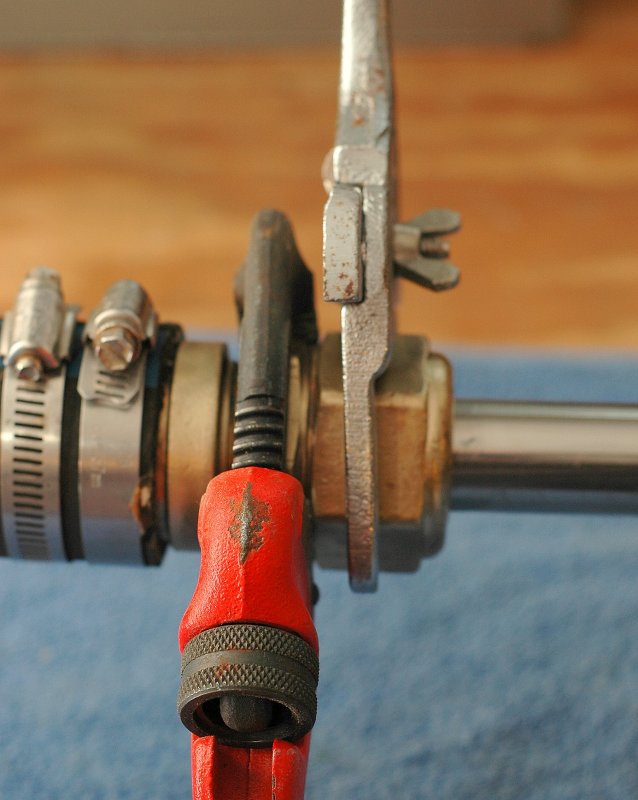

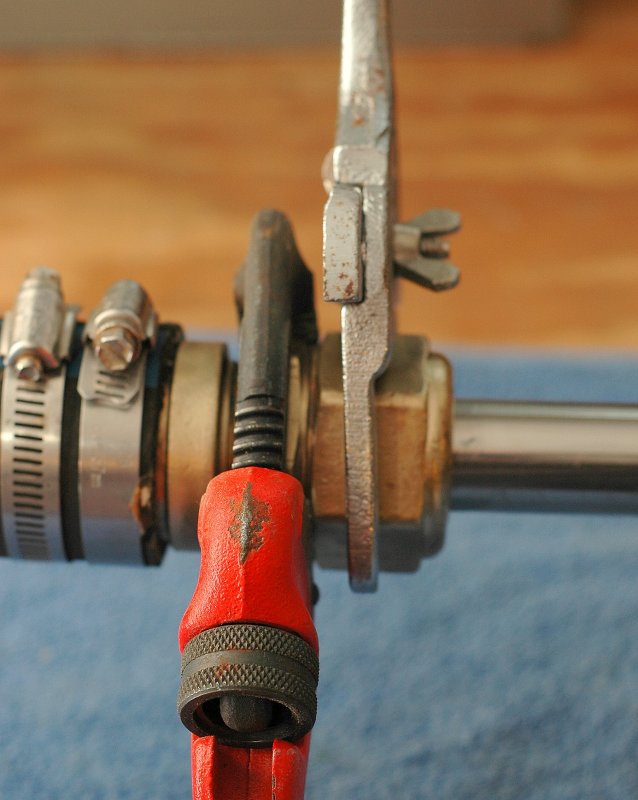

This picture below shows the wrenches I use to loosen and tighten a stuffing box. One wrench is a traditional pipe wrench and the other is a spanner wrench designed for a sink drain. I usually use a smooth jawed pipe wrench but it was misplaced during this photo shoot. Smooth jaws do less damage to the stuffing box nuts. Both of these wrenches are available at Home Depot or a hardware store.

I find it easier to use the pipe wrench on the small & thin locking nut and the spanner wrench on the big nut. It's very important to use wrenches that fit the nuts well. Water pump pliers will, in many cases, not work very well or will not get the nuts tight enough after adjustment. Use good wrenches and not pliers for safety's sake.

If you have tried the above method and the nuts don't break apart use a little bit of PB Blaster penetrating oil. Products like WD40 and Liquid Wrench DON'T WORK WELL AS A TRUE PENETRATING OIL! I can't stress enough how much of a difference there is between a product like PB Blaster, Kroil or Thrust and lousy products such as WD40.

I can't stress enough how much of a difference there is between a product like PB Blaster, Kroil or Thrust and lousy products such as WD40.

Here's a direct quote from a guy who used my web site for directions. Unfortunately after three hours, Liquid Wrench and a broken tool he gave up and emailed me for advice:

"I knew where the cap and the locking nut were, I just couldn't budge them. Went out and bought PB Blaster. Ten minutes after spraying it broke loose. PBB rocks!"

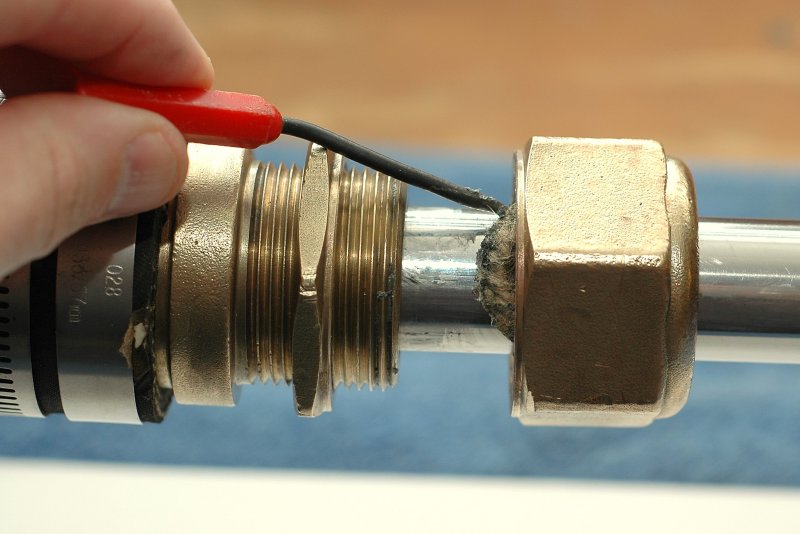

Here's another view of the wrenches and the process. When loosening the nuts the two wrenches are moved towards each other. When tightening the nuts the wrenches are moved away from each other as shown here.

In this photo it's much easier to see the two distinct nuts. Again, the thin one on the left is the locking nut and the big thick nut on the right is the stuffing/packing nut.

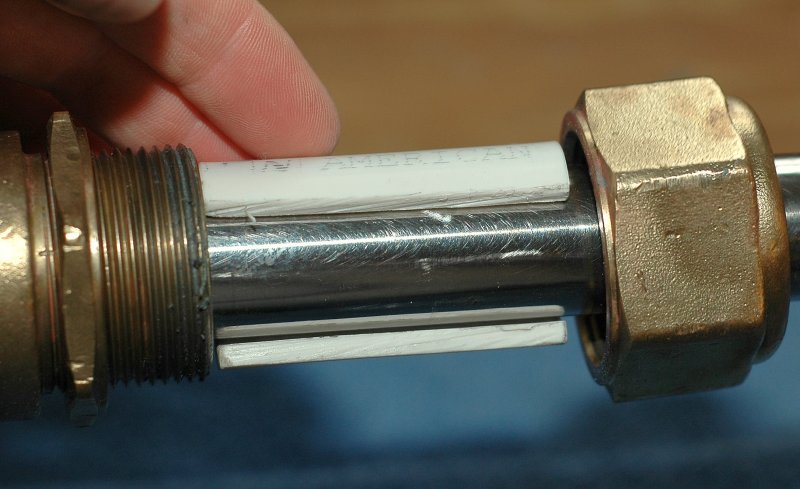

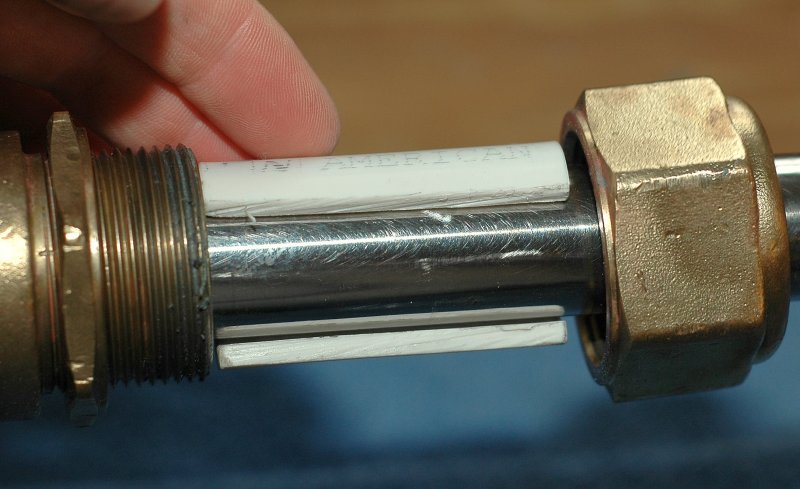

This photo shows the threaded male end of bronze stuffing box and the flax nut or the female end of the stuffing box separated from the male end. The white PVC pipe is my mock up of a fiberglass shaft log.

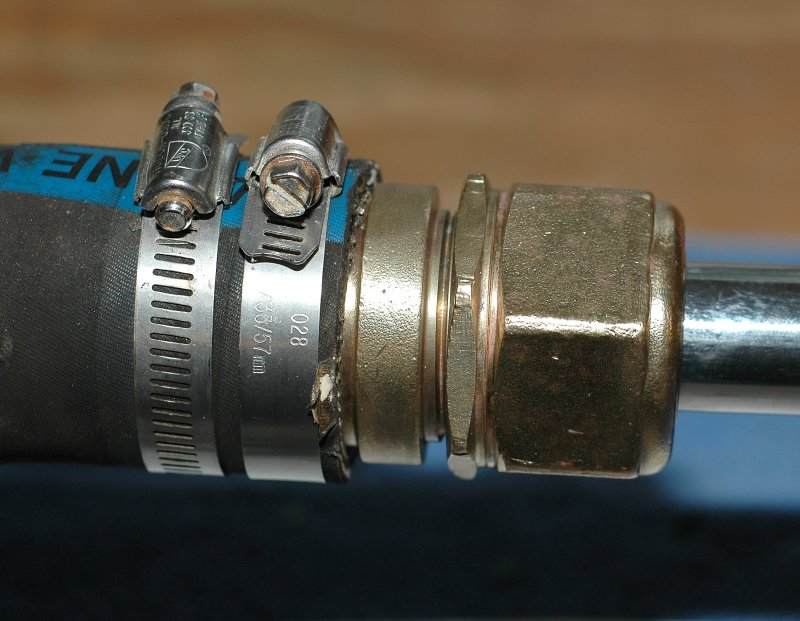

The rubber hose connects the bronze stuffing box to the boat and needs to be replaced periodically. If this rubber hose cracks, and starts leaking, it could sink your boat. Most references suggest replacing the rubber hose every seven to ten years but I have seen them go 20+ if the right hose was used.

If you happen have your shaft out now would be a good time to replace your stuffing box hose. The thick hose below is specifically made for stuffing boxes, it's robust and meant to take the abuse of a drive train. The hose on top is made by Buck Algonquin a premier maker of packing boxes.

This Buck Algonquin hose sized for a 1 3/4" shaft log can be purchased from Hamilton Marine for about $9.00 or less. Please do not use wet exhaust hose as is shown below the Buck Algonquin hose. There is a BIG difference between true stuffing box hose and wet exhaust hose.

When you are replacing your flax packing you will most likely never see this view unless you remove the transmission coupling and take the nut off.

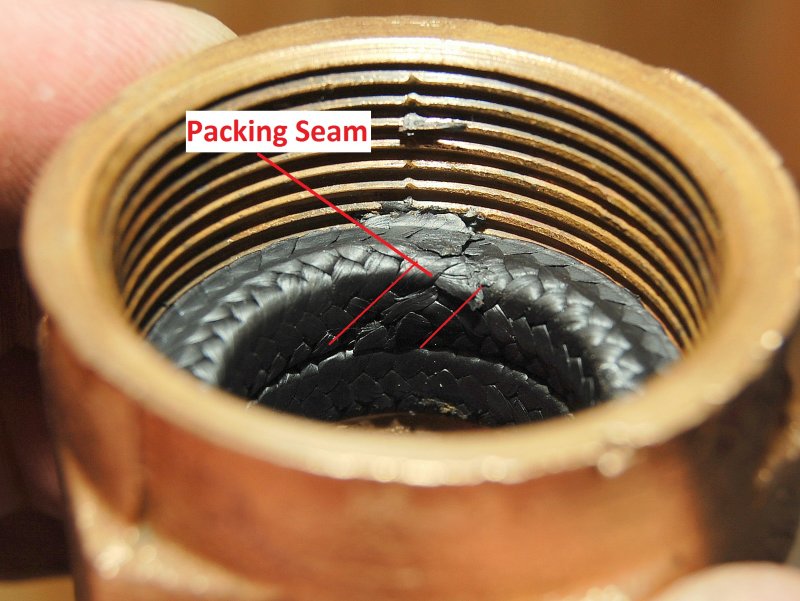

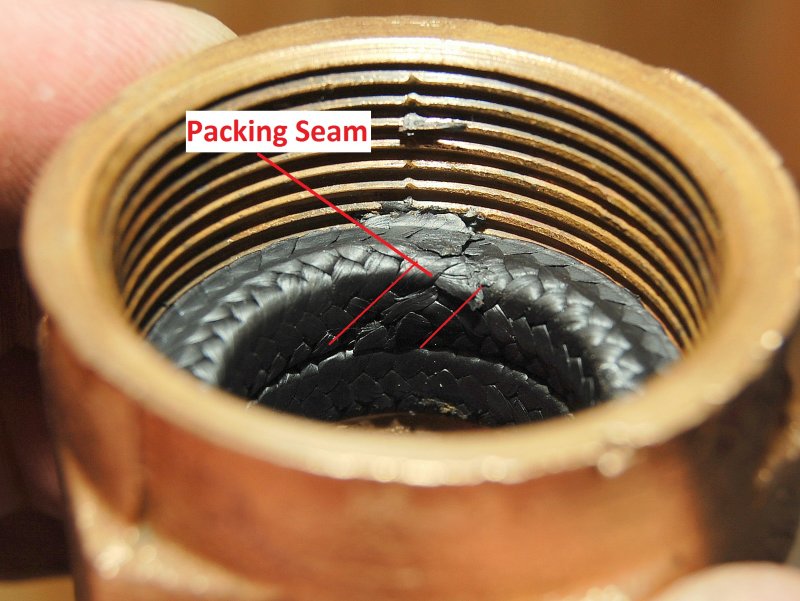

When removing the flax, with a pick, this is what you are trying to dig out! I took this photo to show the female nut with the old flax still in it. You can see the shiny surface where it meets the shaft and the thickness, 3/16", of the flax its self. This particular stuffing box is a 1 inch box from a Catalina 36 and uses three rings 3/16" flax packing.

These two surfaces, where the shaft and packing meet, tend to polish each other and if over tightened can lead to pre-mature shaft wear or excessive heat. Over tightening of the flax nut, and running the stuffing box with no water drips, will eventually wear a grove in the prop shaft and ruin it. It's very important to allow a few drops of water per minute, when the shaft is spinning for lubrication. Even the newer synthetic W.L. Gore GFO packings or their variants should have a a drip or two per minute with the shaft spinning.

This is what the female stuffing box nut should look like, after you have removed all the old packing from it.

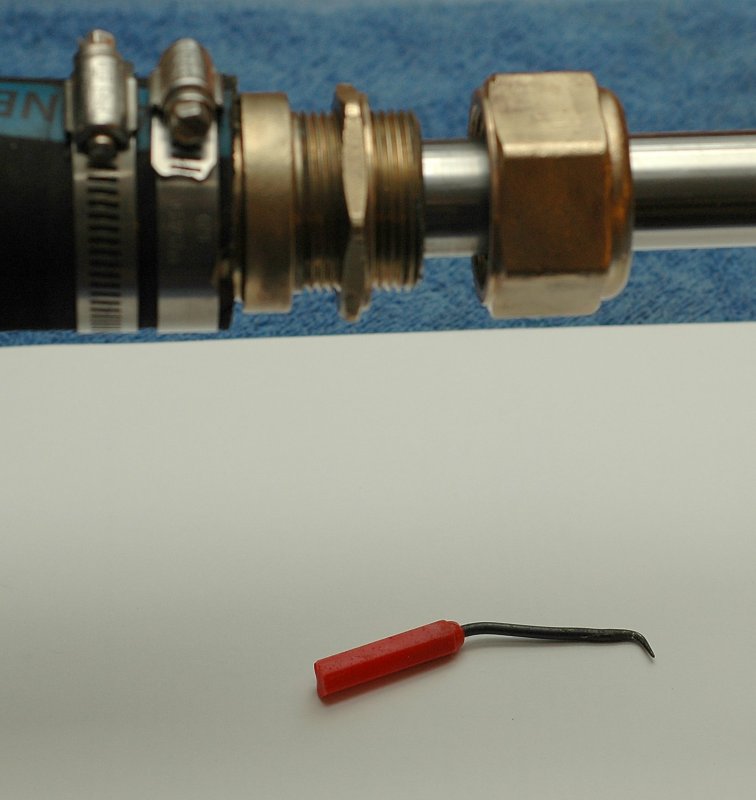

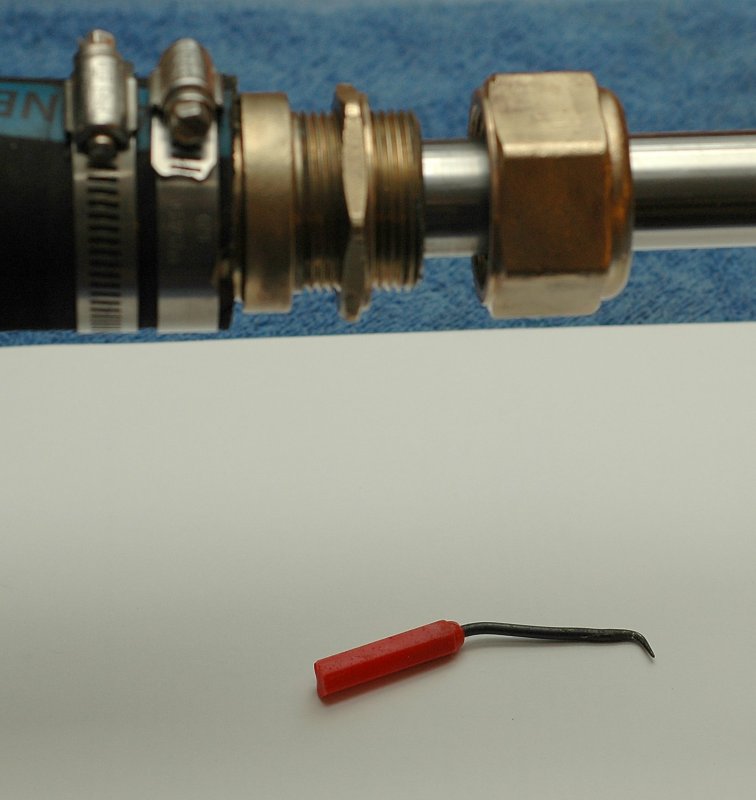

I can't remember where I found this pick, perhaps Sears, but it used to be straight and was designed for removing engine seals! I used a blow torch and a bench vice to create my own, custom made, flax removal tool and it works remarkably well. Even a sheet rock screw can be used to remove flax but in tight spaces it's nice to have a couple of bends in your flax removal tool. Be VERY careful using screws, picks or metals harder than the shaft material to dig out the packing. If you scratch or score the shaft you will have a tough time controlling leakage.

In this photo I left about an inch between the male end of the stuffing box and the female nut. This is typical of the space you'll have on many production boats such as many Ericson's, Pearson's & Catalina's to name a few.

If you have not attempted this type of DIY job before it's best to do it with the boat out of the water for obvious reasons but it can be done in-water relatively easily once you get the hang of it. With the female flax nut removed water will flow in to the boat from between the male end of the box and the shaft.

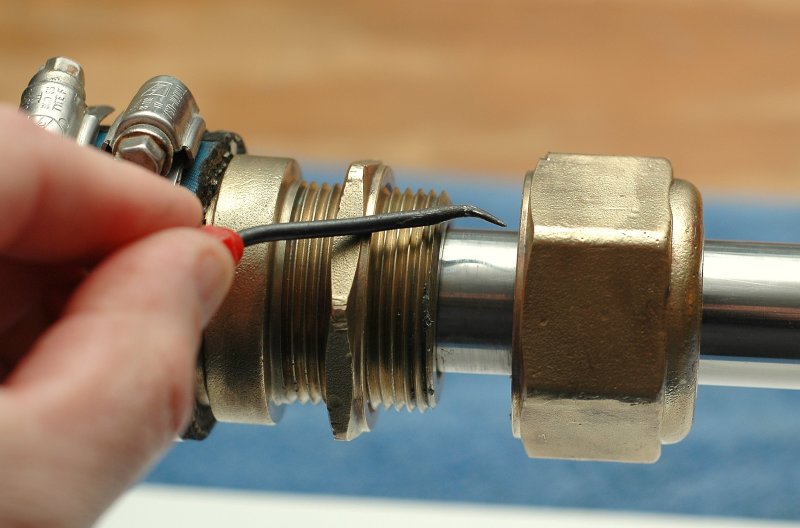

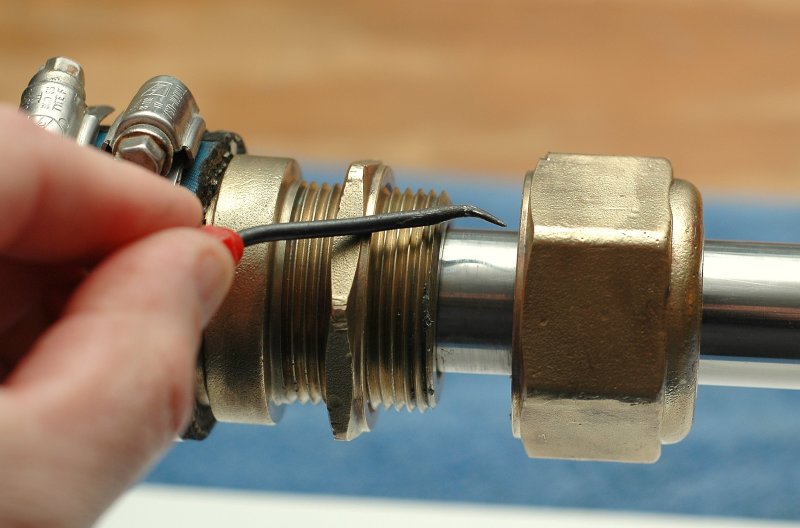

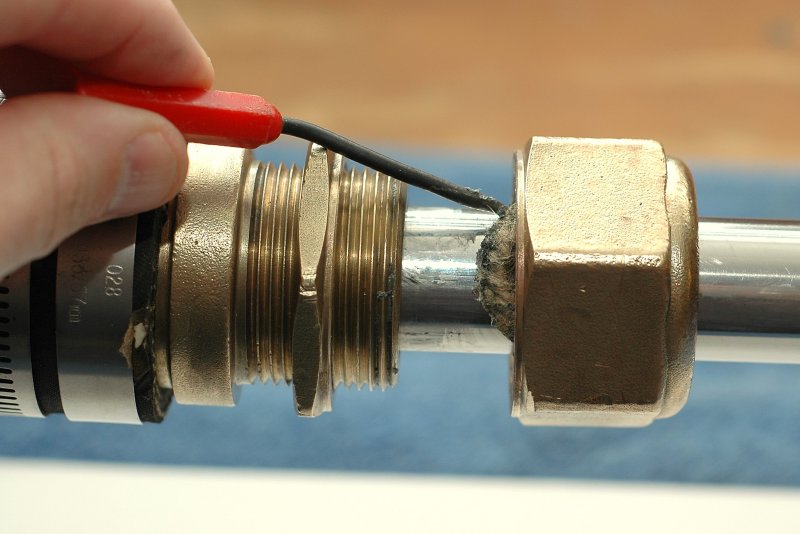

What you can't see in this picture is that the sharp end of my pick is firmly embedded into the first flax ring and ready to pull it out of the nut.

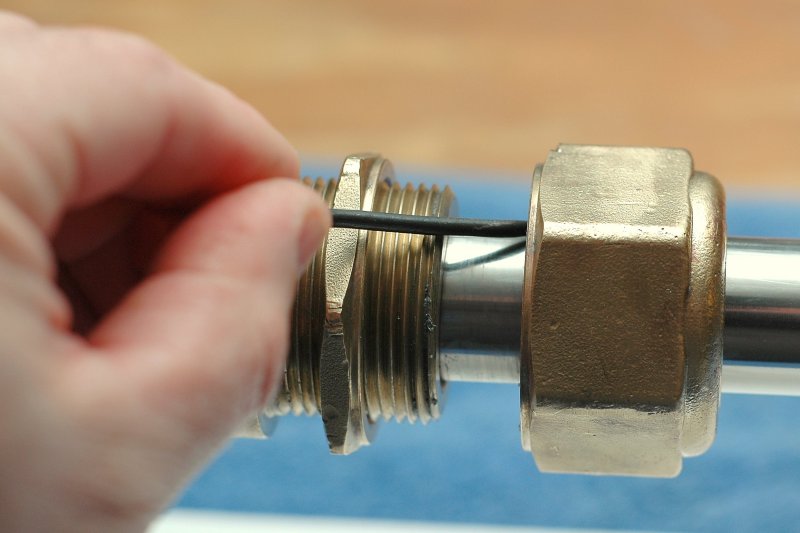

Success. The first flax ring is on its way out.

I don't advise, and can't with a good conscience, suggest the use of "miracle lubes" such as Syntef Stuffing Box Lubricant or the moldable packings like the West Marine Moldable Packing Kit. While some have claimed good success with these miracle clays or lubes I have not and have since heard from many others who also had troubles.

On our old C-36 I installed the West Marine Moldable Dripless Stuffing Kit and it became a nightmare. The green stuff in the picture is the "moldable clay" shown with the two rings of Teflon flax that came out of my female flax nut. Read below for more info on how I had problems with this stuff.

The idea behind this green "moldable clay" is that it will attempt to make your traditional stuffing box dripless. To install it you insert the first ring of flax, then pack in the green clay like substance and insert the second ring making, in essence, a green stuff sandwich.

While the idea of a dripless shaft seal is not new this stuff is probably not the ideal way to go dripless. Not only is it very, very tough to remove with a pick, and replace once installed, it also did not work as advertised for me and the host of others who have emailed me echoing similar issues.

This stuff can plug the male end of the stuffing box with a thick black sediment as I found out. This sediment can only be described as, remnants of the Syntef lubricant and moldable clay. This gray/black goo totally plugged my stuffing box essentially preventing any cooling or lubricating water from getting to the female nut. If left alone for a long enough period it could wind up ruining your prop shaft.

Here you can see the black goo residue on the shaft caused by the "dripless" packing that was clogging my stuffing box. All traditional stuffing boxes require water for lubrication and this "dripless" stuff totally plugged the area between the shaft and the male end of the of the stuffing box as seen in the picture. I do suspect thought that this was a chicken & egg situation as you'll read below.

After the melt down, even with the female nut totally removed, in the water, I was getting, at best, 4 drips per minute with the nut totally off. Please be cautious using this stuff.

My stuffing box actually got so hot, from the lack of water lubrication, that it started to smell and I burned my fingers, enough to blister them, when checking on it.

Keep in mind this did not happen instantaneously and took about 60 hours of run time to accumulate enough Syntef/Clay gunk to clog my stuffing box or enough air trapped in the shaft log to run the box completely dry thus causing this event, chicken & egg?

It ran at a normal temp during and after break in as measured by an infrared thermometer. Some how it either slowly clogged over time or when enough air got trapped in the shaft log it just melted down.. In my opinion this stuff is not suitable for a "tight" shaft log where you don't have sufficient clearance between the shaft and the male end of the stuffing box or a boat where air becomes trapped inside the shaft log if totally made "dripless".

I highly suspect that due to the "dripless" nature of this packing air became trapped in the shaft log. This used to happen frequently with PSS seals before they went to vented or plumbed models that allowed any trapped air to escape. With entrapped air inside the shaft log the packing would have no water lubrication and could then begin to melt and clog the shaft log making it worse, as I suspect may have happened here.

How does air get in there? Docking or anchoring with quick blasts of reverse will send cavitation air bubbles up into the shaft log. I have owned two boats with PSS seals before they went to vented/plumbed models. I found I needed to burp the seal about three to four times per summer to remove trapped air or it would get very hot and begin to make a high pitched squeal from the lack of water lubrication.

If the shaft log is totally sealed or "dripless" the air accumulates up inside it until it causes no lubrication and eventually damage. There is a reason traditional style stuffing boxes are meant to drip. These newer packings should be considered "drips less" not "dripless". Beyond entrapped air, stagnant water in the shaft log can cause crevice corrosion of a prop shaft as you'll see below.

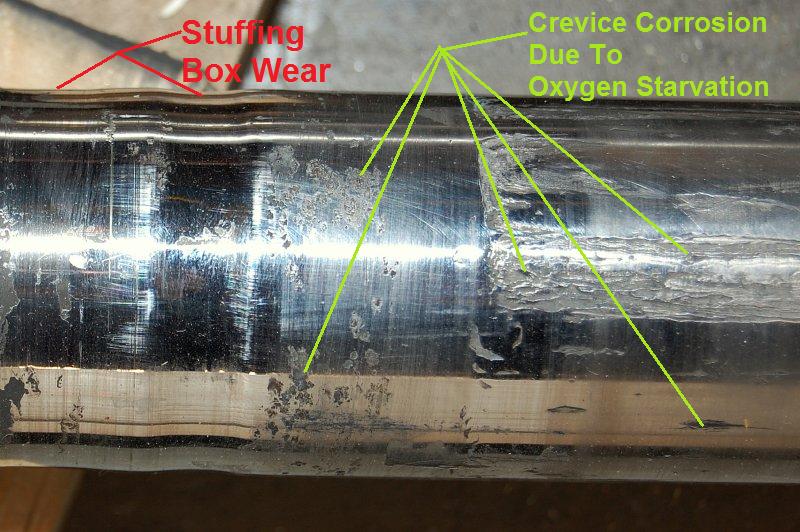

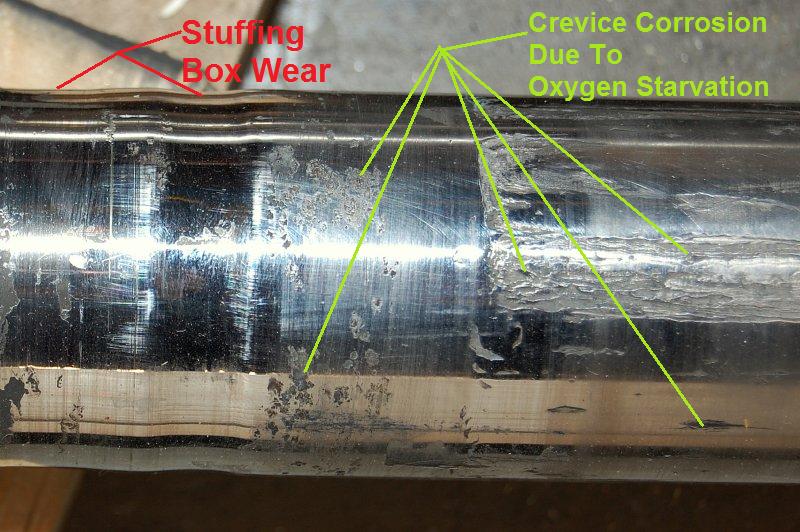

Real Tobin bronze shafting has been long gone for many years now and as such alloys in the stainless family such as Aqumet & Nitronic are now being used. These alloys, like type 304 and 316 SS can suffer from crevice corrosion. Crevice corrosion is worst when a stainless is in contact with seawater and also oxygen starved. This corrosion can happen between wet or leaking decks to the chain plates, or in keel stubs to the stainless keel bolts, but many are unaware that it can happen to prop shafts too. Allowing the packing box to drip helps keep the water in the shaft log from becoming oxygen depleted.

Over the last 10-15 years there has been a dramatic rise in crevice corrosion of prop shafting. With the newer packing materials, and misleading advertising that use phrases like drip-less that cause DIY's to think it means "dripless" not drips less, owners have been starving the packing box area of oxygen by not allowing any fresh oxygenated water to pass through it. This can lead to the destruction of your prop shafting from crevice corrosion. While some packings such as Gore GFO, Ultra-X or GTU may be able to be adjusted to be mostly dry and still some what cool to the touch it is still a bad idea from a crevice corrosion stand point.

Another pit fall when a stuffing box is run totally sealed and "drip free" they can begin to trap air up in the shaft log. All it takes is a quick blast of reverse, and the resulting cavitation bubbles forced up and in, or after sailing in rough weather. Once enough air becomes trapped up in the shaft log the packing box you thought was cool to the touch begins cooking while you least expect it. Even PSS has now moved to selling all their dripless packing boxes with an air vent.

If a stuffing box is allowed to drip it allows for excellent cooling, longer shaft life, less opportunity for crevice corrosion and less opportunity for trapped air to run the box totally dry and cook it.

This shaft had roughly .05" of stuffing box wear and was deemed "scrap metal" by the shafting shop. I have many photos like this. This owner was using Teflon impregnated natural flax and thought when the advertising said "drips less" that it meant it was supposed to be "dripless". Expensive mistake, you should aim to not repeat it.

This photo shows the old Teflon flax packing with the "miracle clay" and the new GTU packing. GTU is a knock off of Gore GFO and frays worse. I used the Gore GFO for half a season on my new boat before switching to a PSS again. The Gore is the best of the flax type packings but it too needs a few drips per minute to run cool and not damage the shaft. My one complaint with this GTU packing made by Western Pacific Trading and sold through West Marine is that it tends to fray easily and does not make the cleanest cuts even when using a brand new razor blade.

Many sail boats have a 1 or 7/8 inch prop shaft and a piece of 1" or 7/8" scrap "dodger tubing" works great as a cutting jig for new flax rings. Use a set of calipers to make sure your "jig" of choice is the same O.D. as your prop shaft and then cut away.

I usually cut the rings in this manner but you could also cut them on the actual prop shaft too. Please cut the rings on the outside of the boat where the shaft exits the hull between the strut and the hull and not at the stuffing box. If you cut the rings on the shaft, at the stuffing box, you run the risk of scoring the shaft and causing a burr that will ruin the new packing and inevitably leak more until the burr gets polished away from the friction. This could take a very long time unless you are in heavily silt laden water...

This may get a little confusing but there actually is a right way and a wrong way to cut the 45 degree angles on your flax rings. In this photo I am holding my razor blade at a 45 degree angle parallel to the shaft. Unfortunately if I cut the rings in this manner they do not seal quite as well. Yes it will work but it is not optimal. Because the shaft nut does not compress the flax on the circumference, like the action created by a hose clamp, cutting it 45 degrees & parallel creates a less than optimal seal.

Wrong Way:

In this picture it's easier to see the 45 degree cut and how the two ends of the packing will join together. The shaft nut will actually compress these two ends together and create a better butt joint than if they were cut vertically for a circumference (think hose clamp) type compression. I told you this was a little confusing. Once the ring is cut be very, very careful to minimize fraying before installing it. If you're using the "imitation" PTFE or traditional "wax" flax fraying is not an issue but with Gore GFO it is.

When cutting the rings be sure to cut them a little loose. It's easily achieved by not wrapping the flax too tightly before making the final cut. Doing this will ensure the ends meet up easily when wrapped around the shaft and that there are no gaps.

Right Way:

This is a good illustration of why the cut should be made the way I have shown above. The compressive force seals the butt ends together nearly perfectly. Little details like this make for an easily adjusted stuffing box with a correct drip to temp ratio.

Here are two of the new GTU rings and the old stuff. Note that there is some fraying even though I tried to minimize it. I have discovered that Western Pacific Tradings GTU packing frays more than Gore GFO or Duramx Ultra-X. GFO and Ultra-X barely fray at all. Perhaps, to prevent fraying with GTU, you could heat up a little wax in a bowl and as soon as you cut the ring dip the ends in the wax like whipping a line. The easy choice is of course to not use GTU and instead use GFO or Ultra-X.

There is actually a fair amount man handling, of the rings, between the time when they are cut and inserted and some measure of fray prevention should be attempted when using Western Pacific Trading GTU or just use GFO or Ultra-X.

The product I used above for this article was Western Pacific Trading GTU from West Marine. Initially I thought it was the Gore GFO I had lying around but GFO has the words "GFO" written on the packing and after going through the photos carefully I could not find the silk screened GFO logo.

I had never had GFO fray but the GTU did. The photo below is Duramax Ultra-X which has a very similar construction and braid to Gore GFO. It does not fray when cut like GTU does. I would try to avoid the GTU packing sold at West Marine if you are concerned about the ends fraying.

Johnson Duramax Ultra-X can be purchased by the foot from Hamilton Marine and it cuts cleanly and is far less money than either GTU or GFO.

Here's an image of a finished 45 degree cut. This was cut from Duramax Ultra-X. It is important to keep in mind that these Gore style packings can dull a razor blade quickly so rotate in a new blade if the old one is cutting poorly. Razor blades are cheap.

When doing this in a boat it is a very good idea to mark the exterior of the nut where each seam is so you can stagger them. Use a packing tool like I show below to compress them into the nut. Only when all rings are in the nut can you then tighten it. Tightening the nut to seat the packing, especially with the newer more slippery packing braids, WILL move the seam and you'll be blind as to where your seams are! Make yourself a seating tool.

This is the last step. In this picture I have two of the three rings wrapped around the shaft in a stepped and alternated order. You must be sure to offset the rings butt joints 1/3, 1/3, 1/3 for a three ring box or 1/2 & 1/2 or said another way 12 o'clock and 6 o'clock for a two ring box.

It's also perfectly fine to wrap one ring at a time and push the nut over it BUT WITHOUT TURNING IT until you get all three rings into the nut and staggered. It's best when using this method of "stuffing rings" to mark the outside of the nut with a Sharpie or pencil as shown above where the joints are and then when all rings are in the nut, and staggered, you can finally thread the nut onto the box.

I custom made my own tool for this & it has a similar thickness to the flax for "stuffing the nut" (see the "tool" below). I don't advise the use of a pick to stuff the flax into the nut as this can cause significant unlaying or twisting of the flax especially with GTU.

When ever possible try to get at least three rings of packing in your stuffing box as most are designed for at least three. Some nuts can actually fit four & if so go for it but make sure you have enough threads to get a good hold for the female nut.

One more very important note is that you really need to use the correct size packing. Going one size to big can eventually wear a groove in the shaft and one size to small will never seal properly. Please use due diligence to determine the proper packing size for your particular stuffing box.

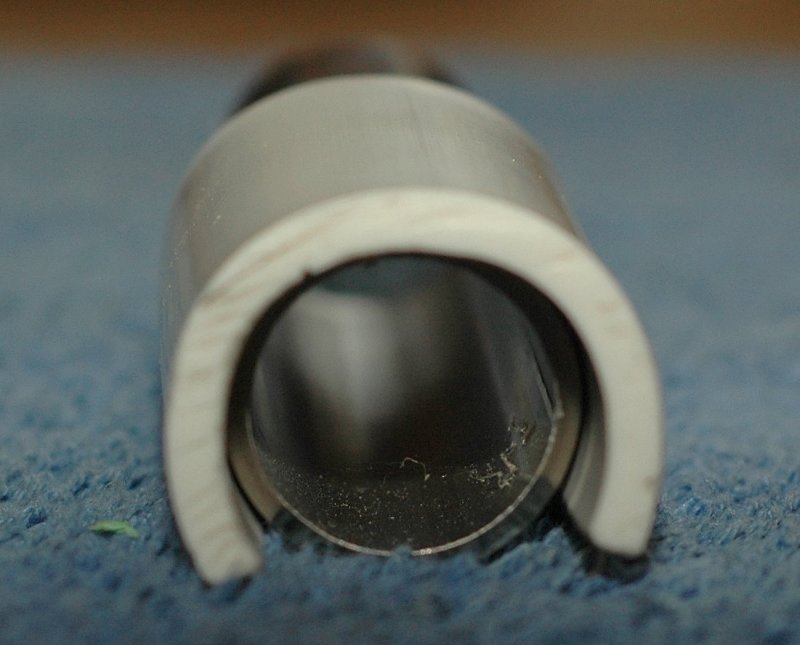

Many folks have asked me how I insert the flax rings into the female nut easily. Well, like anything dealing with boating, it's not always easy but can be done with a little Yankee ingenuity. I decided that in order to keep my ring joints staggered, and to get them properly seated, I needed a new tool.

I wanted a tool that was to be perfectly parallel with the prop shaft when inserting and seating the flax. I also wanted to to seat the flax without causing any twisting and there were no commercially available tools so I made one. Using a screw driver will not give you the correct angle to seat the flax properly and could potentially mess up the joints or put twists in the flax rings which will lead to excessive leakage or heat.

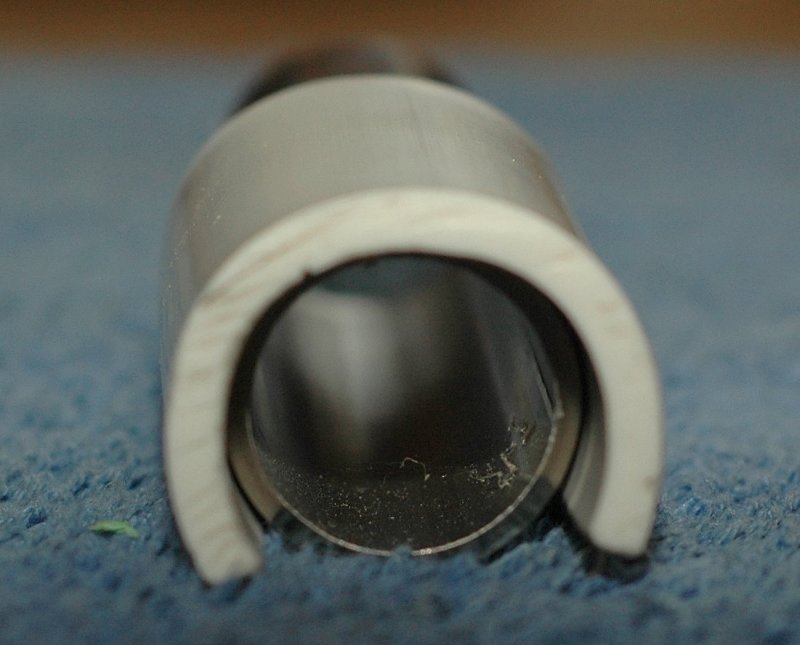

Making this tool took less than five minutes but can really save time and headaches. To build this device I decided to use a short piece of 1-1/4 inch PVC pipe with about 1/3 of it cut out so it would fit over my shaft. I left just enough material so it could clip itself onto the shaft and stay in place without hand holding.

For this process I cut the 1-1/4 inch PVC pipe to 2-1/2 inches long. I then inserted this 2-1/2 inch piece into my bench vise and used a hack saw to make two more cuts. These cuts removed just enough of the 1-1/4 inch PVC to create the device. You're probably wondering why I used 1 1/4 inch PVC if I had a 1 inch prop shaft? Well.. I used it because it's all I had on hand and I also own a heat gun so it was very easy to heat the PVC and wrap it around a piece of scrap 1 inch dodger tubing for a perfect heat formed fit. If you don't own a heat gun dropping PVC into boiling water will soften it enough to "mold" it..

This photo shows the female nut sliding over the "flax seating tool" and seating the flax. The tool works very well and unfortunately no one actually makes one?? Hey I bet West Marine could sell one for $50.00......Hmmmmm...

GFO, GTU & Ultra-X Warning:

While I do like the graphite impregnated packings such as Duramax Ultra-X, Gore GFO or Western Pacific Tradings GTU they can be dangerous to underwater metals. I have used it on my own boat but inspect the Aqualoy 22 prop shaft yearly. I stopped using it in 2012 after some corrosion issues to a less than 1 year old shaft.

Graphite is one of the most noble metals on the galvanic scale and is basically at the top. As such anything in the drive train becomes anodic to the packing. Older "bronze" shafts, really more like a brass because they had high zinc content, can be damaged by these new high tech packings.

This damage happened in one season with in intact prop shaft zinc. The shaft was in fine condition when packed and a year later this is what it looked like. The packing used was Gore GFO a graphite impregnated packing. If you have a bronze shaft use extreme caution with graphite impregnated packing materials.

I don't tend to see these issues with Aqualoy or Nitronic shafting but I do see it with bronze. Please use these packings CAREFULLY, if you choose them, and do check on the shaft periodically.

It should be noted that ABYC P-6 specifically says this:

ABYC P-06

"6.7.4 Graphite impregnated packing material shall not be used because of the possibility of galvanic incompatibility with the shaft material."

That being said there are thousands of happy boaters who have had decent results with these packings but they should not be treated as a "set it and forget it" packing.After year one the shaft should be very carefully inspected for increased corrosion at the packing nut location.

This was 1 year with a bronze shaft

Below is the finished product after installing three new rings of GTU packing.

When initially installing the rings of packing LIGHTLY tighten the nut just until you start to feel some resistance then stop! DO NOT OVER TIGHTEN THE NUT EVER!! the final adjustment will be made after running the motor and shaft for a while.

Proper adjustment for GFO, GTU or Ultra-X is up to a few drops per minute when the shaft is spinning. You'll want it adjusted for nothing more than slightly different from the sea water temp,about a 15 - 20 degree differential, or slightly warmer to the touch but measuring after the shaft has spun for a while. Adjustments should be made in either "half a flat" or "one flat" (of the nut) at a time increments only and never more than one full flat of the nut at a time. W.L. Gore recommends not adjusting the stuffing box until you have run the boat in gear for about two hours of time. This allows the packing to take a set and break in.

When adjusting other types of flax the stuffing box should be relatively cool/warmish to luke warm, at most, and will drip and should drip while the shaft is spinning. The cooler your stuffing box runs means longer shaft life. With GFO they claim temps up to the 125-130F range are technically safe for the packing. This generally means there is not enough cooling flow though. Aim for 15-20 degrees warmer than the ocean or lake temp but a little higher, with GFO, GTU or Ultra-X, will not "kill the deal".

Some boxes will even drip when the shaft is not spinning and this can be entirely normal depending on the condition of your shaft. Do not get stressed if you can not make it drip free at rest as not all shafts are in good enough condition for this to always be the case.

Please do not get in the habit of tightening the stuffing box when "leaving the boat"! Natural flax packings are not elastic and do have a memory, in a sense, and they will not necessarily return to their uncompressed state. Doing this will severely shorten the life of your packing and it will start leaking continuously in short order.

I generally don't like rules-of-thumb for drip rates and really hesitated to even put one on here. My reason for this is that every shaft has differing levels of wear and thus the drip rates are usually different in every installation. The best rule of thumb I've found over the years is the least amount of drips when the shaft is spinning but before the box develops any heat. Again, it's a drip to heat ratio and little to no heat is the most desirable. Traditional flax packing can drip as little as about 5-10 drops a minute if adjusted correctly, while running, and this drip rate allows lubrication of the shaft.

Do not make adjustments to the packing nut, with traditional flax, for at least 24 hours as the plant based flax packing will absorb moisture and swell. This swelling can overheat the stuffing box if it is adjusted to quickly after launch and the swelling has not been accounted for. Pre-mature tightening of traditional flax can result in potential problems. A good and safe practice is to adjust the packing by "half a flat" turns after two hours of use or until you have your drip to heat ration correct. You can actually use an infrared thermometer, often called a pyrometer, to make this adjustment process easier but usually your hand will suffice as a good gauge.

If you want a totally dry bilge then a dripless type such as a PSS or Las-Drop is the way to go.

All done, good luck!

For illustrative purposes I cleaned the stuffing box of it's oxidation and grime with my drill press and a brass wire brush. I used a piece of 1" diameter stainless steel as my makeshift prop shaft to complete the picture and present this as it would look inside a boat.

In this picture what you are actually seeing are two nuts not one. The larger of the two is where the flax resides. The thin nut, on the left, is the locking nut. Once re-packed, & properly adjusted, you lock these nuts together with two large wrenches. If you don't lock these nuts down tight enough, meaning the nuts are each tightened in opposite directions against each other quite tightly, you run the risk of the big nut backing its self off the threads when you put the transmission in reverse. There have been more than a few boats sunk by improper tightening of the stuffing box nuts! Just ask the Boat US insurance division.

This picture below shows the wrenches I use to loosen and tighten a stuffing box. One wrench is a traditional pipe wrench and the other is a spanner wrench designed for a sink drain. I usually use a smooth jawed pipe wrench but it was misplaced during this photo shoot. Smooth jaws do less damage to the stuffing box nuts. Both of these wrenches are available at Home Depot or a hardware store.

I find it easier to use the pipe wrench on the small & thin locking nut and the spanner wrench on the big nut. It's very important to use wrenches that fit the nuts well. Water pump pliers will, in many cases, not work very well or will not get the nuts tight enough after adjustment. Use good wrenches and not pliers for safety's sake.

If you have tried the above method and the nuts don't break apart use a little bit of PB Blaster penetrating oil. Products like WD40 and Liquid Wrench DON'T WORK WELL AS A TRUE PENETRATING OIL!

Here's a direct quote from a guy who used my web site for directions. Unfortunately after three hours, Liquid Wrench and a broken tool he gave up and emailed me for advice:

"I knew where the cap and the locking nut were, I just couldn't budge them. Went out and bought PB Blaster. Ten minutes after spraying it broke loose. PBB rocks!"

Here's another view of the wrenches and the process. When loosening the nuts the two wrenches are moved towards each other. When tightening the nuts the wrenches are moved away from each other as shown here.

In this photo it's much easier to see the two distinct nuts. Again, the thin one on the left is the locking nut and the big thick nut on the right is the stuffing/packing nut.

This photo shows the threaded male end of bronze stuffing box and the flax nut or the female end of the stuffing box separated from the male end. The white PVC pipe is my mock up of a fiberglass shaft log.

The rubber hose connects the bronze stuffing box to the boat and needs to be replaced periodically. If this rubber hose cracks, and starts leaking, it could sink your boat. Most references suggest replacing the rubber hose every seven to ten years but I have seen them go 20+ if the right hose was used.

If you happen have your shaft out now would be a good time to replace your stuffing box hose. The thick hose below is specifically made for stuffing boxes, it's robust and meant to take the abuse of a drive train. The hose on top is made by Buck Algonquin a premier maker of packing boxes.

This Buck Algonquin hose sized for a 1 3/4" shaft log can be purchased from Hamilton Marine for about $9.00 or less. Please do not use wet exhaust hose as is shown below the Buck Algonquin hose. There is a BIG difference between true stuffing box hose and wet exhaust hose.

When you are replacing your flax packing you will most likely never see this view unless you remove the transmission coupling and take the nut off.

When removing the flax, with a pick, this is what you are trying to dig out! I took this photo to show the female nut with the old flax still in it. You can see the shiny surface where it meets the shaft and the thickness, 3/16", of the flax its self. This particular stuffing box is a 1 inch box from a Catalina 36 and uses three rings 3/16" flax packing.

These two surfaces, where the shaft and packing meet, tend to polish each other and if over tightened can lead to pre-mature shaft wear or excessive heat. Over tightening of the flax nut, and running the stuffing box with no water drips, will eventually wear a grove in the prop shaft and ruin it. It's very important to allow a few drops of water per minute, when the shaft is spinning for lubrication. Even the newer synthetic W.L. Gore GFO packings or their variants should have a a drip or two per minute with the shaft spinning.

This is what the female stuffing box nut should look like, after you have removed all the old packing from it.

I can't remember where I found this pick, perhaps Sears, but it used to be straight and was designed for removing engine seals! I used a blow torch and a bench vice to create my own, custom made, flax removal tool and it works remarkably well. Even a sheet rock screw can be used to remove flax but in tight spaces it's nice to have a couple of bends in your flax removal tool. Be VERY careful using screws, picks or metals harder than the shaft material to dig out the packing. If you scratch or score the shaft you will have a tough time controlling leakage.

In this photo I left about an inch between the male end of the stuffing box and the female nut. This is typical of the space you'll have on many production boats such as many Ericson's, Pearson's & Catalina's to name a few.

If you have not attempted this type of DIY job before it's best to do it with the boat out of the water for obvious reasons but it can be done in-water relatively easily once you get the hang of it. With the female flax nut removed water will flow in to the boat from between the male end of the box and the shaft.

What you can't see in this picture is that the sharp end of my pick is firmly embedded into the first flax ring and ready to pull it out of the nut.

Success. The first flax ring is on its way out.

I don't advise, and can't with a good conscience, suggest the use of "miracle lubes" such as Syntef Stuffing Box Lubricant or the moldable packings like the West Marine Moldable Packing Kit. While some have claimed good success with these miracle clays or lubes I have not and have since heard from many others who also had troubles.

On our old C-36 I installed the West Marine Moldable Dripless Stuffing Kit and it became a nightmare. The green stuff in the picture is the "moldable clay" shown with the two rings of Teflon flax that came out of my female flax nut. Read below for more info on how I had problems with this stuff.

The idea behind this green "moldable clay" is that it will attempt to make your traditional stuffing box dripless. To install it you insert the first ring of flax, then pack in the green clay like substance and insert the second ring making, in essence, a green stuff sandwich.

While the idea of a dripless shaft seal is not new this stuff is probably not the ideal way to go dripless. Not only is it very, very tough to remove with a pick, and replace once installed, it also did not work as advertised for me and the host of others who have emailed me echoing similar issues.

This stuff can plug the male end of the stuffing box with a thick black sediment as I found out. This sediment can only be described as, remnants of the Syntef lubricant and moldable clay. This gray/black goo totally plugged my stuffing box essentially preventing any cooling or lubricating water from getting to the female nut. If left alone for a long enough period it could wind up ruining your prop shaft.

Here you can see the black goo residue on the shaft caused by the "dripless" packing that was clogging my stuffing box. All traditional stuffing boxes require water for lubrication and this "dripless" stuff totally plugged the area between the shaft and the male end of the of the stuffing box as seen in the picture. I do suspect thought that this was a chicken & egg situation as you'll read below.

After the melt down, even with the female nut totally removed, in the water, I was getting, at best, 4 drips per minute with the nut totally off. Please be cautious using this stuff.

My stuffing box actually got so hot, from the lack of water lubrication, that it started to smell and I burned my fingers, enough to blister them, when checking on it.

Keep in mind this did not happen instantaneously and took about 60 hours of run time to accumulate enough Syntef/Clay gunk to clog my stuffing box or enough air trapped in the shaft log to run the box completely dry thus causing this event, chicken & egg?

It ran at a normal temp during and after break in as measured by an infrared thermometer. Some how it either slowly clogged over time or when enough air got trapped in the shaft log it just melted down.. In my opinion this stuff is not suitable for a "tight" shaft log where you don't have sufficient clearance between the shaft and the male end of the stuffing box or a boat where air becomes trapped inside the shaft log if totally made "dripless".

I highly suspect that due to the "dripless" nature of this packing air became trapped in the shaft log. This used to happen frequently with PSS seals before they went to vented or plumbed models that allowed any trapped air to escape. With entrapped air inside the shaft log the packing would have no water lubrication and could then begin to melt and clog the shaft log making it worse, as I suspect may have happened here.

How does air get in there? Docking or anchoring with quick blasts of reverse will send cavitation air bubbles up into the shaft log. I have owned two boats with PSS seals before they went to vented/plumbed models. I found I needed to burp the seal about three to four times per summer to remove trapped air or it would get very hot and begin to make a high pitched squeal from the lack of water lubrication.

If the shaft log is totally sealed or "dripless" the air accumulates up inside it until it causes no lubrication and eventually damage. There is a reason traditional style stuffing boxes are meant to drip. These newer packings should be considered "drips less" not "dripless". Beyond entrapped air, stagnant water in the shaft log can cause crevice corrosion of a prop shaft as you'll see below.

Real Tobin bronze shafting has been long gone for many years now and as such alloys in the stainless family such as Aqumet & Nitronic are now being used. These alloys, like type 304 and 316 SS can suffer from crevice corrosion. Crevice corrosion is worst when a stainless is in contact with seawater and also oxygen starved. This corrosion can happen between wet or leaking decks to the chain plates, or in keel stubs to the stainless keel bolts, but many are unaware that it can happen to prop shafts too. Allowing the packing box to drip helps keep the water in the shaft log from becoming oxygen depleted.

Over the last 10-15 years there has been a dramatic rise in crevice corrosion of prop shafting. With the newer packing materials, and misleading advertising that use phrases like drip-less that cause DIY's to think it means "dripless" not drips less, owners have been starving the packing box area of oxygen by not allowing any fresh oxygenated water to pass through it. This can lead to the destruction of your prop shafting from crevice corrosion. While some packings such as Gore GFO, Ultra-X or GTU may be able to be adjusted to be mostly dry and still some what cool to the touch it is still a bad idea from a crevice corrosion stand point.

Another pit fall when a stuffing box is run totally sealed and "drip free" they can begin to trap air up in the shaft log. All it takes is a quick blast of reverse, and the resulting cavitation bubbles forced up and in, or after sailing in rough weather. Once enough air becomes trapped up in the shaft log the packing box you thought was cool to the touch begins cooking while you least expect it. Even PSS has now moved to selling all their dripless packing boxes with an air vent.

If a stuffing box is allowed to drip it allows for excellent cooling, longer shaft life, less opportunity for crevice corrosion and less opportunity for trapped air to run the box totally dry and cook it.

This shaft had roughly .05" of stuffing box wear and was deemed "scrap metal" by the shafting shop. I have many photos like this. This owner was using Teflon impregnated natural flax and thought when the advertising said "drips less" that it meant it was supposed to be "dripless". Expensive mistake, you should aim to not repeat it.

This photo shows the old Teflon flax packing with the "miracle clay" and the new GTU packing. GTU is a knock off of Gore GFO and frays worse. I used the Gore GFO for half a season on my new boat before switching to a PSS again. The Gore is the best of the flax type packings but it too needs a few drips per minute to run cool and not damage the shaft. My one complaint with this GTU packing made by Western Pacific Trading and sold through West Marine is that it tends to fray easily and does not make the cleanest cuts even when using a brand new razor blade.

Many sail boats have a 1 or 7/8 inch prop shaft and a piece of 1" or 7/8" scrap "dodger tubing" works great as a cutting jig for new flax rings. Use a set of calipers to make sure your "jig" of choice is the same O.D. as your prop shaft and then cut away.

I usually cut the rings in this manner but you could also cut them on the actual prop shaft too. Please cut the rings on the outside of the boat where the shaft exits the hull between the strut and the hull and not at the stuffing box. If you cut the rings on the shaft, at the stuffing box, you run the risk of scoring the shaft and causing a burr that will ruin the new packing and inevitably leak more until the burr gets polished away from the friction. This could take a very long time unless you are in heavily silt laden water...

This may get a little confusing but there actually is a right way and a wrong way to cut the 45 degree angles on your flax rings. In this photo I am holding my razor blade at a 45 degree angle parallel to the shaft. Unfortunately if I cut the rings in this manner they do not seal quite as well. Yes it will work but it is not optimal. Because the shaft nut does not compress the flax on the circumference, like the action created by a hose clamp, cutting it 45 degrees & parallel creates a less than optimal seal.

Wrong Way:

In this picture it's easier to see the 45 degree cut and how the two ends of the packing will join together. The shaft nut will actually compress these two ends together and create a better butt joint than if they were cut vertically for a circumference (think hose clamp) type compression. I told you this was a little confusing. Once the ring is cut be very, very careful to minimize fraying before installing it. If you're using the "imitation" PTFE or traditional "wax" flax fraying is not an issue but with Gore GFO it is.

When cutting the rings be sure to cut them a little loose. It's easily achieved by not wrapping the flax too tightly before making the final cut. Doing this will ensure the ends meet up easily when wrapped around the shaft and that there are no gaps.

Right Way:

This is a good illustration of why the cut should be made the way I have shown above. The compressive force seals the butt ends together nearly perfectly. Little details like this make for an easily adjusted stuffing box with a correct drip to temp ratio.

Here are two of the new GTU rings and the old stuff. Note that there is some fraying even though I tried to minimize it. I have discovered that Western Pacific Tradings GTU packing frays more than Gore GFO or Duramx Ultra-X. GFO and Ultra-X barely fray at all. Perhaps, to prevent fraying with GTU, you could heat up a little wax in a bowl and as soon as you cut the ring dip the ends in the wax like whipping a line. The easy choice is of course to not use GTU and instead use GFO or Ultra-X.

There is actually a fair amount man handling, of the rings, between the time when they are cut and inserted and some measure of fray prevention should be attempted when using Western Pacific Trading GTU or just use GFO or Ultra-X.

The product I used above for this article was Western Pacific Trading GTU from West Marine. Initially I thought it was the Gore GFO I had lying around but GFO has the words "GFO" written on the packing and after going through the photos carefully I could not find the silk screened GFO logo.

I had never had GFO fray but the GTU did. The photo below is Duramax Ultra-X which has a very similar construction and braid to Gore GFO. It does not fray when cut like GTU does. I would try to avoid the GTU packing sold at West Marine if you are concerned about the ends fraying.

Johnson Duramax Ultra-X can be purchased by the foot from Hamilton Marine and it cuts cleanly and is far less money than either GTU or GFO.

Here's an image of a finished 45 degree cut. This was cut from Duramax Ultra-X. It is important to keep in mind that these Gore style packings can dull a razor blade quickly so rotate in a new blade if the old one is cutting poorly. Razor blades are cheap.

When doing this in a boat it is a very good idea to mark the exterior of the nut where each seam is so you can stagger them. Use a packing tool like I show below to compress them into the nut. Only when all rings are in the nut can you then tighten it. Tightening the nut to seat the packing, especially with the newer more slippery packing braids, WILL move the seam and you'll be blind as to where your seams are! Make yourself a seating tool.

This is the last step. In this picture I have two of the three rings wrapped around the shaft in a stepped and alternated order. You must be sure to offset the rings butt joints 1/3, 1/3, 1/3 for a three ring box or 1/2 & 1/2 or said another way 12 o'clock and 6 o'clock for a two ring box.

It's also perfectly fine to wrap one ring at a time and push the nut over it BUT WITHOUT TURNING IT until you get all three rings into the nut and staggered. It's best when using this method of "stuffing rings" to mark the outside of the nut with a Sharpie or pencil as shown above where the joints are and then when all rings are in the nut, and staggered, you can finally thread the nut onto the box.

I custom made my own tool for this & it has a similar thickness to the flax for "stuffing the nut" (see the "tool" below). I don't advise the use of a pick to stuff the flax into the nut as this can cause significant unlaying or twisting of the flax especially with GTU.

When ever possible try to get at least three rings of packing in your stuffing box as most are designed for at least three. Some nuts can actually fit four & if so go for it but make sure you have enough threads to get a good hold for the female nut.

One more very important note is that you really need to use the correct size packing. Going one size to big can eventually wear a groove in the shaft and one size to small will never seal properly. Please use due diligence to determine the proper packing size for your particular stuffing box.

Many folks have asked me how I insert the flax rings into the female nut easily. Well, like anything dealing with boating, it's not always easy but can be done with a little Yankee ingenuity. I decided that in order to keep my ring joints staggered, and to get them properly seated, I needed a new tool.

I wanted a tool that was to be perfectly parallel with the prop shaft when inserting and seating the flax. I also wanted to to seat the flax without causing any twisting and there were no commercially available tools so I made one. Using a screw driver will not give you the correct angle to seat the flax properly and could potentially mess up the joints or put twists in the flax rings which will lead to excessive leakage or heat.

Making this tool took less than five minutes but can really save time and headaches. To build this device I decided to use a short piece of 1-1/4 inch PVC pipe with about 1/3 of it cut out so it would fit over my shaft. I left just enough material so it could clip itself onto the shaft and stay in place without hand holding.

For this process I cut the 1-1/4 inch PVC pipe to 2-1/2 inches long. I then inserted this 2-1/2 inch piece into my bench vise and used a hack saw to make two more cuts. These cuts removed just enough of the 1-1/4 inch PVC to create the device. You're probably wondering why I used 1 1/4 inch PVC if I had a 1 inch prop shaft? Well.. I used it because it's all I had on hand and I also own a heat gun so it was very easy to heat the PVC and wrap it around a piece of scrap 1 inch dodger tubing for a perfect heat formed fit. If you don't own a heat gun dropping PVC into boiling water will soften it enough to "mold" it..

This photo shows the female nut sliding over the "flax seating tool" and seating the flax. The tool works very well and unfortunately no one actually makes one?? Hey I bet West Marine could sell one for $50.00......Hmmmmm...

GFO, GTU & Ultra-X Warning:

While I do like the graphite impregnated packings such as Duramax Ultra-X, Gore GFO or Western Pacific Tradings GTU they can be dangerous to underwater metals. I have used it on my own boat but inspect the Aqualoy 22 prop shaft yearly. I stopped using it in 2012 after some corrosion issues to a less than 1 year old shaft.

Graphite is one of the most noble metals on the galvanic scale and is basically at the top. As such anything in the drive train becomes anodic to the packing. Older "bronze" shafts, really more like a brass because they had high zinc content, can be damaged by these new high tech packings.

This damage happened in one season with in intact prop shaft zinc. The shaft was in fine condition when packed and a year later this is what it looked like. The packing used was Gore GFO a graphite impregnated packing. If you have a bronze shaft use extreme caution with graphite impregnated packing materials.

I don't tend to see these issues with Aqualoy or Nitronic shafting but I do see it with bronze. Please use these packings CAREFULLY, if you choose them, and do check on the shaft periodically.

It should be noted that ABYC P-6 specifically says this:

ABYC P-06

"6.7.4 Graphite impregnated packing material shall not be used because of the possibility of galvanic incompatibility with the shaft material."

That being said there are thousands of happy boaters who have had decent results with these packings but they should not be treated as a "set it and forget it" packing.After year one the shaft should be very carefully inspected for increased corrosion at the packing nut location.

This was 1 year with a bronze shaft

Below is the finished product after installing three new rings of GTU packing.

When initially installing the rings of packing LIGHTLY tighten the nut just until you start to feel some resistance then stop! DO NOT OVER TIGHTEN THE NUT EVER!! the final adjustment will be made after running the motor and shaft for a while.

Proper adjustment for GFO, GTU or Ultra-X is up to a few drops per minute when the shaft is spinning. You'll want it adjusted for nothing more than slightly different from the sea water temp,about a 15 - 20 degree differential, or slightly warmer to the touch but measuring after the shaft has spun for a while. Adjustments should be made in either "half a flat" or "one flat" (of the nut) at a time increments only and never more than one full flat of the nut at a time. W.L. Gore recommends not adjusting the stuffing box until you have run the boat in gear for about two hours of time. This allows the packing to take a set and break in.

When adjusting other types of flax the stuffing box should be relatively cool/warmish to luke warm, at most, and will drip and should drip while the shaft is spinning. The cooler your stuffing box runs means longer shaft life. With GFO they claim temps up to the 125-130F range are technically safe for the packing. This generally means there is not enough cooling flow though. Aim for 15-20 degrees warmer than the ocean or lake temp but a little higher, with GFO, GTU or Ultra-X, will not "kill the deal".

Some boxes will even drip when the shaft is not spinning and this can be entirely normal depending on the condition of your shaft. Do not get stressed if you can not make it drip free at rest as not all shafts are in good enough condition for this to always be the case.

Please do not get in the habit of tightening the stuffing box when "leaving the boat"! Natural flax packings are not elastic and do have a memory, in a sense, and they will not necessarily return to their uncompressed state. Doing this will severely shorten the life of your packing and it will start leaking continuously in short order.

I generally don't like rules-of-thumb for drip rates and really hesitated to even put one on here. My reason for this is that every shaft has differing levels of wear and thus the drip rates are usually different in every installation. The best rule of thumb I've found over the years is the least amount of drips when the shaft is spinning but before the box develops any heat. Again, it's a drip to heat ratio and little to no heat is the most desirable. Traditional flax packing can drip as little as about 5-10 drops a minute if adjusted correctly, while running, and this drip rate allows lubrication of the shaft.

Do not make adjustments to the packing nut, with traditional flax, for at least 24 hours as the plant based flax packing will absorb moisture and swell. This swelling can overheat the stuffing box if it is adjusted to quickly after launch and the swelling has not been accounted for. Pre-mature tightening of traditional flax can result in potential problems. A good and safe practice is to adjust the packing by "half a flat" turns after two hours of use or until you have your drip to heat ration correct. You can actually use an infrared thermometer, often called a pyrometer, to make this adjustment process easier but usually your hand will suffice as a good gauge.

If you want a totally dry bilge then a dripless type such as a PSS or Las-Drop is the way to go.

All done, good luck!