Stop. Do not rebed unless leaks are apparent. I got T-boned by a Coast Guard cutter last summer (my fault, don't ask for details), and have spent the past year trying to get just one stanchion rebeded correctly. In my fifth try, I've now switched from machine screw to wood screw for more bite. Leave well enough alone.

Deadline,

Leaks are not always apparent when a bolt goes through a wood cored deck as the balsa or marine ply absorb much of the leak before it has a chance to drip. Often times it is not until the wood is saturated that the moisture begins to drip on the inside of the vessel. It is always imperative to never seal the INSIDE of the deck with bedding compound. You want to see the leak so you don't require a 20-30k deck job. A moisture meter and spot soundings around deck hardware are often the only signs of moisture ingress.

Add hull liners and bolts that are not visible to the mix and you can turn a deck into a pile of mushy oatmeal in rather short order if you are not watching it. I own a moisture meter for more than just looking at new boats. I monitor my own decks with it.

Are you really serious that you have stanchions held in by screws? I certainly hope for your safety,and the safety of your guests, that they are going into an embedded metal plate and are tapped into it.

Catalina is using embedded aluminum plates in the deck, I really, really dislike this construction. I ripped one clean out of the aluminum and had to through bolt it to repair when my boat was hit on her mooring by another boat. In one season I already had the beginnings of aluminum/stainless corrosion on some of the fittings. When re-bedding I used Tef-Gell on all the threads contacts of stainless to aluminum.

Generally the best course of action is through bolted with large backing plates or fender washers. Re-bedding is really not that difficult except for access. Many of the production builders do a REALLY poor job of bedding. I rebedded my 2005 Catalina 310 in 2006 cause I had MULTIPLE leaks. This is 150% unacceptable on a 1 year old boat. Heck it would be unacceptable on a ten year old boat with the exception of perhaps the occasional stanchion.

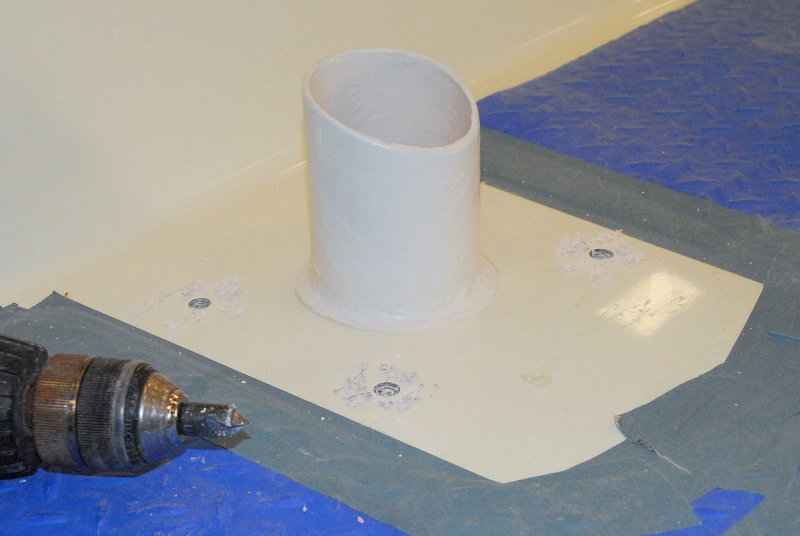

If they would just take the time to countersink/bevel/chamfer the deck, leaks would mostly be a thing of the past and greatly reduced. Sadly, I guess the extra 30 seconds per fitting is too much to ask from a production builder...

Morris Yachts and Hinckley & J Boat, among other quality builders, all countersink the holes slightly before bedding. The big three don't...

Also keep in mind that your leaking stanchion may be the EXIT source for a leak further up the deck that is migrating through the deck and out your stanchion. If that is the case you will never seal it up until you find the primary leak.

A Morris Yachts deck fitting hole getting countersunk:

All four of these chamfers, combined, took under 30 seconds: