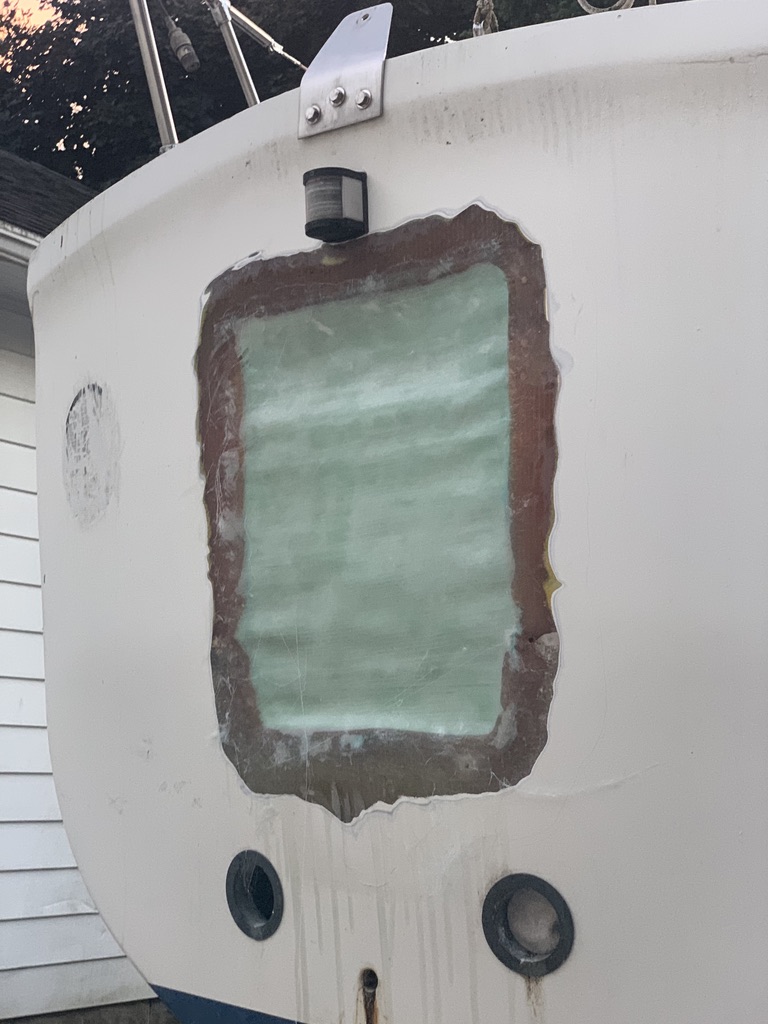

I'm repairing the hole in the transom seen here. There are dimples near the top and bottom of the base layer of fiberglass. Since the photo, I've sanded back/added a few more layers of glass. In the top dimple, I tried to fill it in by adding 5 or so extra layers of 1708 biaxial glass but even that didn't bring the dent out much. I wanted to ask. Is it okay for use thickened epoxy/ (west systems 708 fairing filler) to bring those dimples out a bit? and then after it's all a bit more smooth - start adding layers of glass again? Thanks!

Putting Fairing/Filler Between Fiberglass Layers? Filling Dimples

- Thread starter withintheruins14

- Start date

I’d be inclined to just keep going with layers of glass over the whole section, then fair it out with epoxy fairing compound after you’ve built up the thickness.

You could try using chopped strand mat instead of cloth to get a thicker layer.

Epoxy and chopped strand mat do not play well together. The mat is held together with a styrene based glue that dissolves in polyester resin but not in epoxy. This makes it harder for the epoxy to saturate the cloth and requires more epoxy.You could try using chopped strand mat instead of cloth to get a thicker layer.

I believe there are mat products that are epoxy compatible, if you go this route, be sure to get the correct cloth.

I'm inclined to follow @Davidasailor26's advice. The important dimension is the thickness of the patch. Once it is thick enough, then use fairing compound to smooth it out.

OP doesn't say whether he's using polyester or epoxy resin. My suggestion was based on his using polyester.Epoxy and chopped strand mat do not play well together. The mat is held together with a styrene based glue that dissolves in polyester resin but not in epoxy. This makes it harder for the epoxy to saturate the cloth and requires more epoxy.

I believe there are mat products that are epoxy compatible, if you go this route, be sure to get the correct cloth.

I'm inclined to follow @Davidasailor26's advice. The important dimension is the thickness of the patch. Once it is thick enough, then use fairing compound to smooth it out.

epoxy resin, but TY for the suggestionOP doesn't say whether he's using polyester or epoxy resin. My suggestion was based on his using polyester.

Those look like sags. Did you just lay glass across a big opening, without using a backing/form, tacking in core, or prelaminating a sheet? I don't understand why there are such big ripples. The most common method would be to screw a sheet metal form to one side and lay glass against that, and then grind out and fishing the other side. You need to have something firm to roll against.

jssailem

SBO Weather and Forecasting Forum Jim & John

- Oct 22, 2014

- 23,796

Once committed to epoxy you are in for a penny in for a pound.

Just epoxy no glass will become brittle. The strength is in the glass soaked with resin. You can get different glass cloth thicknesses all require careful soaking of the fibers to cure without voids. Mat fibers have a styrene binder to hold them together. Polyester Resin breaks down the styrene. Epoxy resin does not so some fibers are left not soaked, and weak.

The dimples you are seeing is why most patches of this size are made with glass over a stiff core that "fills" the hole.

Now you need to continue laying the layers till you are "Close to even" with the top edges of the original transom. You can then sand smooth and fill the voids revealed from sanding with the epoxy filler. Be sure to wash the layers to remove any amine blush that appears on the epoxy surface as it becomes solid. It will foul your ability to add more layers by inhibiting thte chemical bond.

The filler is similar to bondo. You add too much bondo and the surface is never right. The filler allows you to fill the small indentations so that you get a smooth finished surface.

Just epoxy no glass will become brittle. The strength is in the glass soaked with resin. You can get different glass cloth thicknesses all require careful soaking of the fibers to cure without voids. Mat fibers have a styrene binder to hold them together. Polyester Resin breaks down the styrene. Epoxy resin does not so some fibers are left not soaked, and weak.

The dimples you are seeing is why most patches of this size are made with glass over a stiff core that "fills" the hole.

Now you need to continue laying the layers till you are "Close to even" with the top edges of the original transom. You can then sand smooth and fill the voids revealed from sanding with the epoxy filler. Be sure to wash the layers to remove any amine blush that appears on the epoxy surface as it becomes solid. It will foul your ability to add more layers by inhibiting thte chemical bond.

The filler is similar to bondo. You add too much bondo and the surface is never right. The filler allows you to fill the small indentations so that you get a smooth finished surface.

In my case, I used multiple layers of tape to form the backing and pushed a piece of plywood against that as best as I could from the inside. We went on for a long time about this in another post so - topic of this post is not why they are there but what can I do ;P Thanks all!Those look like sags. Did you just lay glass across a big opening, without using a backing/form, tacking in core, or prelaminating a sheet? I don't understand why there are such big ripples. The most common method would be to screw a sheet metal form to one side and lay glass against that, and then grind out and fishing the other side. You need to have something firm to roll against.

The reason I asked is that it could actually be easier to start over with a better form. I can't lay eyes on, but sometimes. like parralel parking, it's best to start over with the lessons learned. I've built hull extensions and filled holes that big, and the starting point is a good, strong, fair form that will NOT require significant fairing. I resently made a cabin-top plate for a hull about that size, and I spent a few hours making a form from fiberglass shower suround material and 1x4 ribs that was stiff and matched the curve. The time was amply repaid by time saved later on. Virtually no fairing and a good surface to roll against.In my case, I used multiple layers of tape to form the backing and pushed a piece of plywood against that as best as I could from the inside. We went on for a long time about this in another post so - topic of this post is not why they are there but what can I do ;P Thanks all!

My first fiberglass projects were a trainwreck I'm not proud of. I'm not trying to criticize, I promise. But that was 30 years ago and I've learned a lot.

jssailem

SBO Weather and Forecasting Forum Jim & John

- Oct 22, 2014

- 23,796

You are correct. Not the end of the world.

More than I would want to fill with "filler".

I would use a straight edge to identify the major high and low points. Then concentrate on just those areas. Using a felt tip pen to outline the areas to work on.

More than I would want to fill with "filler".

I would use a straight edge to identify the major high and low points. Then concentrate on just those areas. Using a felt tip pen to outline the areas to work on.

There is nothing wrong with using some filler, just top it with a few layers of finish cloth to reinforce it. Just make up some thickened epoxy and screed it across with a board. Repeat as needed.I've laid 2-3 layers of glass over the area and a few extra layers in the top dimple. Raining today or I'd have finished it up.

Video from today: