The 'seal' for straight thread pipe connections is not the threads but the 'butt end' forming a 'ring seal' with the mating part. The threads primarily to apply the correct force to drive the butt end into the other fitting, etc. For straight thread connections its the butt end that makes the 'seal' --- just like with compression or flared connections.Neil, if you are saying you used 4200 to seal the threads between the thru-hull and the ball valve you will have an extremely difficult time removing those valves without spinning the thru-hull fitting. You or the next owner will be cursing you when that day comes.

pipe tape or pipe dope?

- Thread starter gettinthere

- Start date

- Status

- Not open for further replies.

The only straight threaded fittings I know of for below water use are Marelon and that is how they seal but you become very limited in valve handle angle because once bottomed there is very little room for adjustment.The 'seal' for straight thread pipe connections is not the threads but the 'butt end' forming a 'ring seal' with the mating part. The threads primarily to apply the correct force to drive the butt end into the other fitting, etc. For straight thread connections its the butt end that makes the 'seal' --- just like with compression or flared connections.

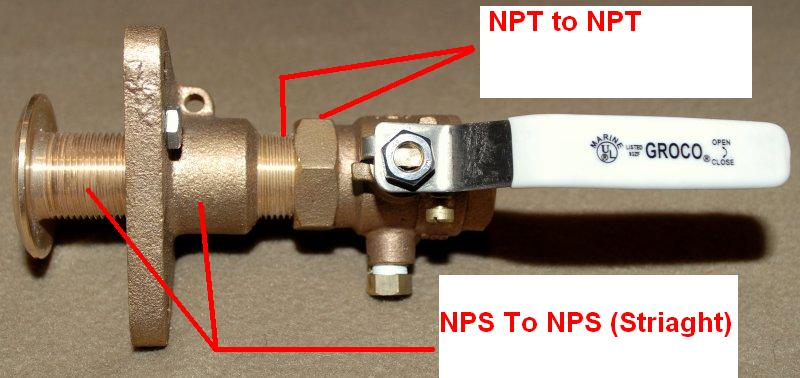

With NPT to NPT you have a lot more no-leak range for adjustment. All the UL Marine bronze fittings are NPT-NPT unless you mismatch an NPS thru-hull with an NPT valve which is against manufacturer suggestions and the ABYC standards.

The only one that is not NPT-NPT is the thru-hulls to seacock but they do not bottom out in a seacock for their seal as they are most often cut to length on the job. They seal around the mushroom head, why it is dished out for sealant, not as an NPS-NPS seal does. A marine sealant is preferred for this seal. But once inside the boat and dealing with NPT to NPT tape, dope or a combo of both is the standard sealing method for an NPT-NPT interface across all industries I know of...

Most seacock have NPS, etc. (straight threads) on the side that connect/mate to the thruhull, and with NPT on the 'inside' side. You usually have to 'special order' the throuhull fitting with STRAIGHT threads from marine suppliers - NPT (tapered thread) wont properly MATE with NPS straight thread profiles, they are incompatible.

(Somewhere in the dim past I think I remember you did an 'article' on this) ;-)

www.groco.net/00-scks-valves/bv-dimens-w-chart.htm

(Somewhere in the dim past I think I remember you did an 'article' on this) ;-)

www.groco.net/00-scks-valves/bv-dimens-w-chart.htm

MS

You were the person who turned me on to the thruhull-flange adapter-valve setup that Groco makes.

Care to repost that info here?

I bed the thru hull, backing block & the flange adapter with 4200, then use dope & tape to attach the valve, hose barb and whatever on top of that.

You were the person who turned me on to the thruhull-flange adapter-valve setup that Groco makes.

Care to repost that info here?

I bed the thru hull, backing block & the flange adapter with 4200, then use dope & tape to attach the valve, hose barb and whatever on top of that.

Here it is:MS

You were the person who turned me on to the thruhull-flange adapter-valve setup that Groco makes.

Care to repost that info here?

I bed the thru hull, backing block & the flange adapter with 4200, then use dope & tape to attach the valve, hose barb and whatever on top of that.

Flanged adapter:

NPS to NPT (on left) NPT to NPT (on right):

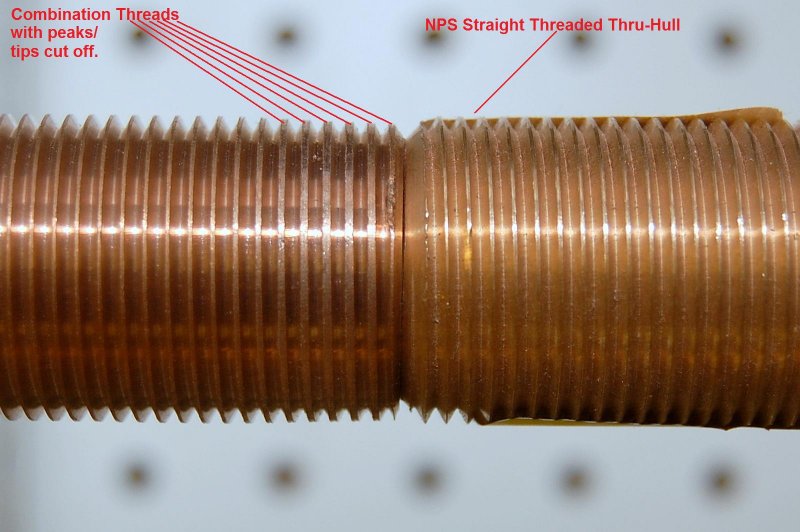

Rich,The mating of an NPS male fitting to a female NPT fitting can be improved somewhat by running a NPT die over the end (to put a taper on the threads) of the NPS threads.

Rich

With the thickness of today's thru-hulls that is likely the last thing you want to do as you'd have very little wall thickness left.. The wall thickness is already about equal to that of a penny and in some thru-hulls less than that.

The manufacturers do sell "combination threaded" thru-hulls but this is NOT a true NPT thread. It is an NPS thread with the peaks of the first few threads shaved off so it can bury deeper and have some more thread engagement. It is a band-aid approach but certainly better than a full thread mis-match.

Here is a combination thread compared to a straight thread:

Being a retired pipefitter with 35 years in a large integrated steel mill, I can appreciate the discussion on sealants and threaded fittings. Especially Maine Sails input from the "supply side". We preferred using teflon tape because it was easy to carry and no mess to apply. It was the only sealant allowed on oxygen lines because it was oil free. It also the preferred sealant for steam lines as dope would dry up and set from the heat and would make later disassembly a real PITA. We did all the maintenance and a lot of our own construction. The only thing it wasn't used on was high pressure hydraulic systems because we were told that it would "creep" out of the threads from the pressure. Otherwise tape and dope was used interchangeably on any other application. Funny, but, using both at the same time I guess didn't occur to us. Least-wise I don't recall seeing it.

Teflon tape had other uses. It could be unrolled and twisted into a string and used to fill gaps and as a makeshift gasket. Great stuff. In fact round and square packing used in the glands of pump shafts and valve stems was made up of bundles of teflon tape.

Rich

Teflon tape had other uses. It could be unrolled and twisted into a string and used to fill gaps and as a makeshift gasket. Great stuff. In fact round and square packing used in the glands of pump shafts and valve stems was made up of bundles of teflon tape.

Rich

Point taken. I spun one replacing a valve on my last haulout. No big deal, really. Rebedded the thru-hull and was good to go, felt better about it too. Note that the original valve wasn't leaking, just getting a little too stiff for my liking.Neil, if you are saying you used 4200 to seal the threads between the thru-hull and the ball valve you will have an extremely difficult time removing those valves without spinning the thru-hull fitting. You or the next owner will be cursing you when that day comes.

- Status

- Not open for further replies.