Rob,

What I see here are a few

compounded issues:

#1 I see what looks a lot like silicone contamination. The 5200 appears to have separated

cleanly from the deck and this is highly indicative of gelcoat silicone contamination. 3M5200 is tenacious stuff but even silicone contamination can cause 5200 to fail to adhere, I see it regularly.

#2 I also see a welded chain plate cover on an application that ideally should have a free-floating plate (non-welded). There is clearly movement between the hull liner anchor point and the deck, and with a welded plate it will move more than the 5200 can accommodate. All polyurethane sealants continue to harden over time despite reaching a high level of fairly elastic cure pretty quickly. As they age they become less elastic. The ratings for elongation do not take aging into account and IMHO are a bit misleading. Still even if you planned on 500% elongation before failure, and your plate squished the 5200 to 1/64", you only have about 0.06" of allowable movement before a failure. This is why the chainplate hole through the deck needs plenty of chamfered gap around it so your allowable movement before failure is sufficient.

#3 When it comes time to make new chain-plates, and yours already have some corrosion, I would

not go with welded covers. It is a rare production boat that can pull off welded covers. To do welded covers means ZERO movement between anchor point and deck and that rarely happens on boats like this.. I would urge you to make the cover plates large enough so they can be through bolted using machine screws, washers and nylock nuts.. This way the chain plate can move independently of the cover plate, and with a highly elastic sealant like Bed-It, you will not have these issues. You still need to sand away the silicone but once that is done you should be leak free for a long while.

When I am rebedding chain plates this is the process I use:

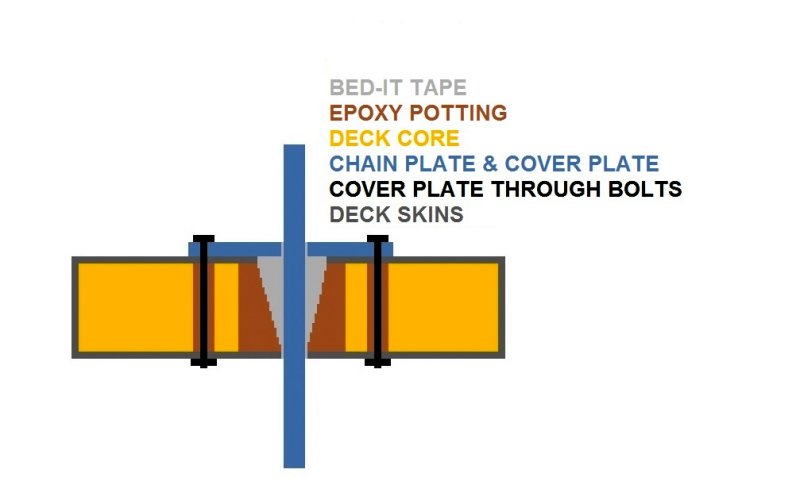

-- Chamfer hole through deck so it is slightly wider at top than bottom. This allows for sufficient movement of the chain plate. On most many boats the chain plates will move slightly.

-- Route core away and epoxy pot the chain plate deck penetration hole as well as cover plate through bolt holes.

-- Pack in the Bed-It Tape using a silicone kitchen tool so it is still slightly proud of deck.

-- Cover back of cover plate with Bed-It and follow bedding procedure for standard deck hardware. Tighten the cover plate slowly..