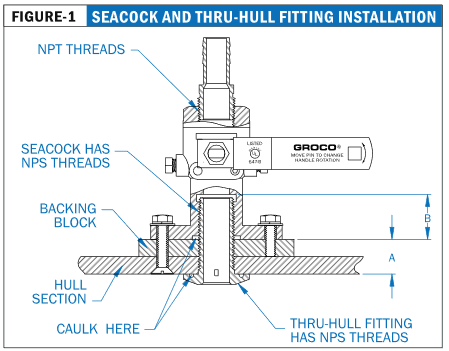

Hi, new to the forum here. I have been reading up on seacocks and thru hulls as i will be replacing them on my new-to-me Hunter. I am familiar with NPT threaded fittings which form a seal by interference between the two parts, with some help from a lubricant or sealer. And also that we shouldn't force NPT female threads onto NPS male threads and hope for the best. What I can't quite see is, if a "proper" thru hull has NPS male theads, and a "proper" seacock has NPS female threads, where does the actual seal take place? Reading the installation instructions that Groco for instance publishes it is not clear what seals the NPS threads. The instructions call for the installer to shorten the thru hull to 1/4" less than the full threaded depth of the seacock. So the seal doesn't take place there as it does with some hydraulic fittings (JIS for example). Apparently the inboard end of the seacock is NPT, so easy going from there. Are the NPS threads t be coated with a sealer and ther eis no actual mechanical interference fit?

NPS threads question

- Thread starter pbknowles

- Start date

Thru-Hulls are straight thread and ball valves are tapered thread. To comply with the ABYC standards threads need to be be compatible. There is a thru-hull with a "combination thread" but they are hard to find and won't meet the ABYC standards, strengths wise, in smaller sizes. Best to use a proper flanged seacock, not a ball valve stuck on a thru-hull fitting.

Start with these articles:

https://marinehowto.com/category/plumbing/

.

Start with these articles:

https://marinehowto.com/category/plumbing/

.

Thanks for the reply and link. I now see where the seal takes place. Unfortunately the design leaves the section of the thru hull extending up into the seacock living perpetually in stagnant seawater as there is no seal created by the NPS threads. This seems far from ideal, but I guess it has been done this way a long time and as long as everything is bronze and not brass ok.

Having just re-read a couple of the articles, I still can't find any mention of how the NPS threaded through-hull seals. Isn't it so that an NPS plumbing joint requires a seal of some kind, a washer, gasket, O-ring, something? Where does that go in this assembly?

Last edited:

The seal takes place at the spots marked "caulk here". this makes sense for the mushroom head where it passes through the skin. But for the interior, it leaves the extended length of the through hull as well as the female threads of the seacock soaking in stagnant seawater.

John, do you have a reference for that? I don't think it's so. the NPS threaded fixtures I have, including a Scandvik sill cock, European tempering valve, water meter, and almost all of my brewery equipment, require a gasket, usually a flat, fiber or bonded washer, sometimes a flat neoprene washer. I don't think "goo" on a straight pipe thread is going to seriously seal anything.The NPS plumbing seals with the application of a plumbing goo or sealant applied to the thread.

Interesting, I found the Groco instruction sheet from which @pbknowles excerpted the figure, and it seems they don't specify a gasket, only the caulk.

@jviss, you make a good point.

In NPS plumbing around my house and rentals, I have opted to use a product like "Blue Monster Heavy-Duty Industrial Grade Thread Sealant" generally referred to as "pipe Dope".

In reviewing the work of MaineSail, (Replacing Thru-Hulls and Seacocks - Marine How To) you can see in the images a use of pipe dope.

Not sure is intended, or referenced as an example of what not to use as the text does not mention any specific "doping" of the thru hull threads when inserting the thru hull into the flanged base shown above. The flanged base is NPS on the hull side and NPT on the valve side.

Maine Sail does state that he uses SikaFlex 291. He prefers it to 3M's 4200 product.

Here is the SikaFlex 291 on the bottom of the flanged base. It looks to be a to form a seal and I would expect that some of the "goo" when assembled will get into the NPS threads on the Flange Base.

In completing the thru hull assembly, his advise is to

Trying to follow this sequence the probability of SikaFlex291 filling the threads of the NPS flange is high. Since the manufacture of the flange base with the NPS threads does not provide an "O" ring or any "gasket" material I am left to conclude the splashed over sealant used to fit the parts together serves to seal the fitting.

Anecdotal evidence at best, but in my opinion likely.

In NPS plumbing around my house and rentals, I have opted to use a product like "Blue Monster Heavy-Duty Industrial Grade Thread Sealant" generally referred to as "pipe Dope".

In reviewing the work of MaineSail, (Replacing Thru-Hulls and Seacocks - Marine How To) you can see in the images a use of pipe dope.

Not sure is intended, or referenced as an example of what not to use as the text does not mention any specific "doping" of the thru hull threads when inserting the thru hull into the flanged base shown above. The flanged base is NPS on the hull side and NPT on the valve side.

Maine Sail does state that he uses SikaFlex 291. He prefers it to 3M's 4200 product.

Here is the SikaFlex 291 on the bottom of the flanged base. It looks to be a to form a seal and I would expect that some of the "goo" when assembled will get into the NPS threads on the Flange Base.

In completing the thru hull assembly, his advise is to

"Once the nuts are tight climb back out of the boat and remove the thru-hull fitting. Clean it with Acetone then lather it up with a marine sealant of your choice. Now use a step wrench, and a large adjustable wrench, and tighten the thru-hull into the flange from outside the boat.

Once everything is tight clean up the ooze from the sealant, including any that oozed out up inside the through hull and around the exterior. Be sure to clean excess sealant from the counter sunk bolt heads so you’re ready to fill and fair the exterior with a vinyl ester filler such as 3M Marine Premium Filler"

Trying to follow this sequence the probability of SikaFlex291 filling the threads of the NPS flange is high. Since the manufacture of the flange base with the NPS threads does not provide an "O" ring or any "gasket" material I am left to conclude the splashed over sealant used to fit the parts together serves to seal the fitting.

Anecdotal evidence at best, but in my opinion likely.

From Groco's document on this topic:

https://www.groco.net/media/file/file/i/b/ibv-fbv-tech-blltn.pdf

NPS THREADS Standard straight pipe threads that when assembled with other NPS threaded components will provide free and loose fitting mechanical joints without pressure tightness. (Emphasis mine. jv)

NPT THREADS Standard tapered pipe threads that when assembled with other NPT threaded components and a sealer will produce a pressure tight joint.

Here's another article on this:

What is the difference between NPT and NPS thread? | U.S. Plastic

What is the difference between NPT and NPS thread?

NPS = National Pipe Straight

NPT = National Pipe Thread

Both NPT and NPS have the same thread angle, shape, and pitch (threads per inch). However, NPT threads are tapered and NPS threads are straight (parallel). Both threads have a 60° included angle and have flat peaks and valleys.

Tapered Pipe Thread is commonly found on ends of pipe, nipples and fittings (i.e. couplings, elbows, tees, etc.). Note: Sharply angled threads are very critical to joint being tight with no leaks. Thread sealant or tape is typically required to complete the seal.

Straight Pipe Threads need a gasket or O-ring to create a seal. (Emphasis mine. jv)

While NPT and NPS threads will engage, they do not seal properly with each other.

https://www.groco.net/media/file/file/i/b/ibv-fbv-tech-blltn.pdf

NPS THREADS Standard straight pipe threads that when assembled with other NPS threaded components will provide free and loose fitting mechanical joints without pressure tightness. (Emphasis mine. jv)

NPT THREADS Standard tapered pipe threads that when assembled with other NPT threaded components and a sealer will produce a pressure tight joint.

Here's another article on this:

What is the difference between NPT and NPS thread? | U.S. Plastic

What is the difference between NPT and NPS thread?

NPS = National Pipe Straight

NPT = National Pipe Thread

Both NPT and NPS have the same thread angle, shape, and pitch (threads per inch). However, NPT threads are tapered and NPS threads are straight (parallel). Both threads have a 60° included angle and have flat peaks and valleys.

Tapered Pipe Thread is commonly found on ends of pipe, nipples and fittings (i.e. couplings, elbows, tees, etc.). Note: Sharply angled threads are very critical to joint being tight with no leaks. Thread sealant or tape is typically required to complete the seal.

Straight Pipe Threads need a gasket or O-ring to create a seal. (Emphasis mine. jv)

While NPT and NPS threads will engage, they do not seal properly with each other.

I agree. Never disagreed. The question is how do you seal the NPS thread thru hull?

No gasket or O ring is designed nor provided for the groco flange fitting. At least not that I find.

Further NPT threaded thru hulls though mentioned and rumored were not to be found.

So how do you suggest you install the thru hull? I have at the least offered an argument that appears to address the issue.

No gasket or O ring is designed nor provided for the groco flange fitting. At least not that I find.

Further NPT threaded thru hulls though mentioned and rumored were not to be found.

So how do you suggest you install the thru hull? I have at the least offered an argument that appears to address the issue.

I'm not disagreeing with you John, you obviously seal it as Groco recommends. It's just that this is not the 'conventional' method of sealing NPS pipe threads.So how do you suggest you install the thru hull? I have at the least offered an argument that appears to address the issue.

Here's my conclusion on this. Groco and others are using NPS threads not as pipe threads per se, but simply as machine threads, to clamp the mushroom head against the hull. They might as well be any machine thread. The seal comes from the sealant that is applied to the mushroom thru-hull, and the seacock flange. The top end of the seacock, or the top of a thru-hole with combination threads have NPT threads, and we know how these seal.

I disagree, and apparently, so does Groco. The bit I quoted earlier comes from their seacocks instruction sheet:Sealant will work on the threads. There is very little pressure involved here. There are millions of these in service without leaks. The gaskets and O rings you refer to are used only on machine applications typically with much higher pressures involved.

The static pressure is about 1/2 psi per foot of depth. The dynamic can be several times that. A couple of psi will eventually push past NPS threads.NPS THREADS Standard straight pipe threads that when assembled with other NPS threaded components will provide free and loose fitting mechanical joints without pressure tightness.

Note that Groco doesn't say to coat the NPS threads, they say where to apply the sealant, and it's under the head of the mushroom and under the flange.

The Teflon tape and most pipe "Dope" used with NPT threads are not sealants but primarily lubricants used so that the NPT threads jam tighter together creating a better seal. This is absolutely true of Teflon tape and mostly true of pipe dopes, though some of them have some sealing properties. Pipe dopes typically do not harden in the anaerobic (oxygen excluded) part of the joint, so it can be seen that they are not "sealants".

I agree that the NPS threads only purpose in life is to create clamping force, and that it could be any thread. If you do goop up the entire length of the NPS threads, even with something soft like silicone it will be very tough to get it apart again as that stuff will firm up and assuming the parts were clean when gooped, you will be fighting shearing that stuff off the threads all the way out.

Having access to machining capability, I think when the time comes I will machine the inboard faces of my new through hulls true and also machine a Teflon washer/seal to the correct thickness and diameter to fit at the gap indicated at the top of dimension "B" in the illustration. That should keep the threads dry, and no need for goop on them.

I agree that the NPS threads only purpose in life is to create clamping force, and that it could be any thread. If you do goop up the entire length of the NPS threads, even with something soft like silicone it will be very tough to get it apart again as that stuff will firm up and assuming the parts were clean when gooped, you will be fighting shearing that stuff off the threads all the way out.

Having access to machining capability, I think when the time comes I will machine the inboard faces of my new through hulls true and also machine a Teflon washer/seal to the correct thickness and diameter to fit at the gap indicated at the top of dimension "B" in the illustration. That should keep the threads dry, and no need for goop on them.

Well, mine do not leak. I would advise against a gasket because it will be difficult to have the gasket compress and have the mushroom just tight against the hull at the same time. Most likely either the hull to mushroom will be tight and the gasket loose or worse, the gasket tight and the hull to mushroom loose. No need to overthink this simple installation, IMHO. Another useful point; If you do not own the special tool to hold the mushroom portion during installation, you can insert a box wrench end into the opening and hold it with another wrench or channel locks. Just select one that fits well. Also, if you ever have to remove a seacock that has hardened sealant inside the threads; apply some heat and then turn it right off.