Mooring Line Lengths

- Thread starter Peregrine

- Start date

- Status

- Not open for further replies.

It will

It will depend on local ordinances. Around here the system shown in the Hamilton marine catalog is the preferred system and many municipalities have adopted it.

This is probably a lot more info than you want or need but why not..

Mooring tips:

#1 Big heavy chain gives good caternary effect and prevents shock loading.

#2 Moorings are usually designed at a 2:1 or 3:1 max scope, depending upon local regulations, so this means heavy chain is a must if you want any caternary and protection from shock loading.

#3 Chain wears where the links meet. Anchors are not constant duty but moorings are. Moorings are exposed to wear & link degradation 24/7 365 though they should always be winterized to prevent additional chain wear..

#4 The biggest chain, or wire diameter, you can buy will last you the longest.

#5 Galvanized chain adds no real long term benefit as the link wear chews through it rather quickly anyway so self colored chain is fine.

#6 Long link mooing chain is a good option because shackles fit better through it.

#7 You should have a top chain and a bottom chain. The top chain will be lighter than the bottom chain. A good rule of thumb is that the bottom or really heavy chain be 1.5 times max water depth. You will replace the top chain every three to four years depending on your location but bottom chain can last as long as 7-10 if big enough..

#8 Depending on the bottom type you can use: Mud = Mushroom, pyramid or screw. Hard bottoms = Large diameter granite (low and flat is generally considered best). Cement is generally considered a bad idea, by just about every municipality that has studied mooring field failures, and some municipalities have banned it's use as it loses a significant amount of weight bellow water and there are no real "standards". In this vein many have also banned "home made" moorings of engine blocks, cement filled barrels and such. Lots of municipalities now require any home made mooring to first be inspected by the local harbor master.

#9 Many municipalities only allow certain approved mooring companies to set, retrieve, inspect and maintain moorings. The anchorage I'm in now has over 1200 boats and they are very, very strict as to what you can and can not do and who can actually set, retrieve, inspect or work on moorings!

#10 Buy and use the biggest swivel you can. The swivel sees the most wear in the system. I use a 1" swivel and it is money well spent. The swivel should be located just under the ball so you can easily visually inspect it. In areas like a river, with reversing currents, sometimes two swivels are necessary, one below the ball and one between the top and bottom chain.

Feel free to watch this video and you'll see the types of mooring conditions boats in Maine can deal with in the winter and during Nor' Easters. Most boats up here use the Wayne Hamilton mooring protocol as shown bellow. None of the boats in the video broke free despite a few of them having huge breaking waves bashing them. One actually rolled about 80 degrees and popped back up but did not break free.

Please ignore my video skills..

Enjoy...

Why Not to Cut Corners On Your Mooring System (LINK)

Photo Courtesy of Hamilton Marine (LINK)

This is my bottom chain for a 36 footer..

I would not advise an above the ball connection for a number of reasons one being hull scratches and gouges from the shackles the other is tangles & wraps.

Bellow the ball pendant attachments, at least in our anchorage and along the Maine Coast, cause the least amount of problems if done correctly.

With above ball connections, unless you have multiple floats, and this is key, the equator, waist or widest portion of your mooring ball sits bellow the surface of the water you will have problems. If the waist or "equator" of your above the ball connection floats above the surface of the water, seemingly no matter how many floats you have, it will wrap the ball and then get sucked down to the chain as the boat pulls. If the waist is below the surface the floats make the pendants pull over the ball, not under, causing no tangles. With ten+ foot tides up here it is tough to always keep the waist of the ball below the surface as the chain gets lighter and heavier as the tide rises and falls.

I have studied this rather extensively if Falmouth, and by a large margin, below the ball connections wrap much less than above the ball despite the judicious use of floats. It is my conclusion, after physically watching it actually take place, that the "waist" factor is the single biggest problem and cause of wraps not the amount of floats you have.

The ball below marked "Mahoney" is my boat neighbor. I was on board when we had a lull and wind shift. His boat gently moved around the ball and the floats kept the pendants on the surface but circled around the ball. As soon as the wind came up from the other direction and the pendants tightened they were immediately sucked down and into the chain because they were caught under the waist. I took the photo the rowed over and untangled his pendants..

Above ball tangle with floats:

Another one:

Oops another:

Pendants:

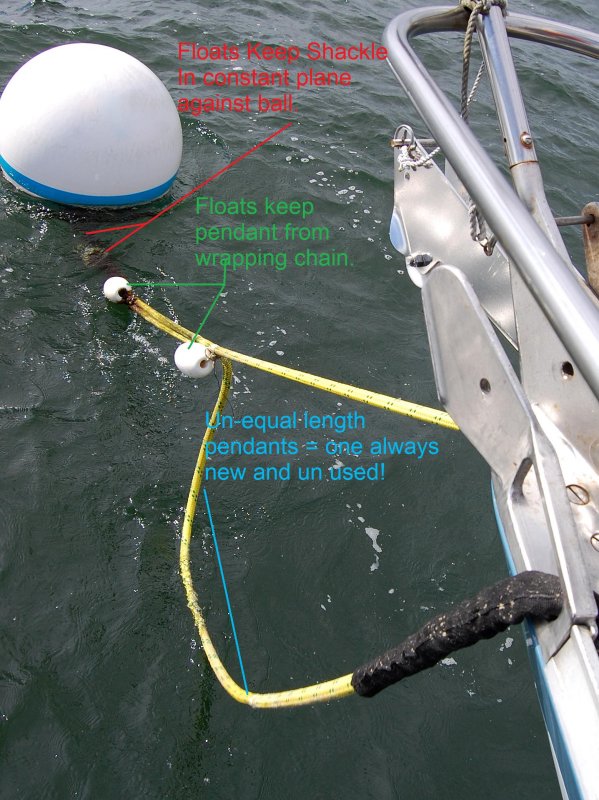

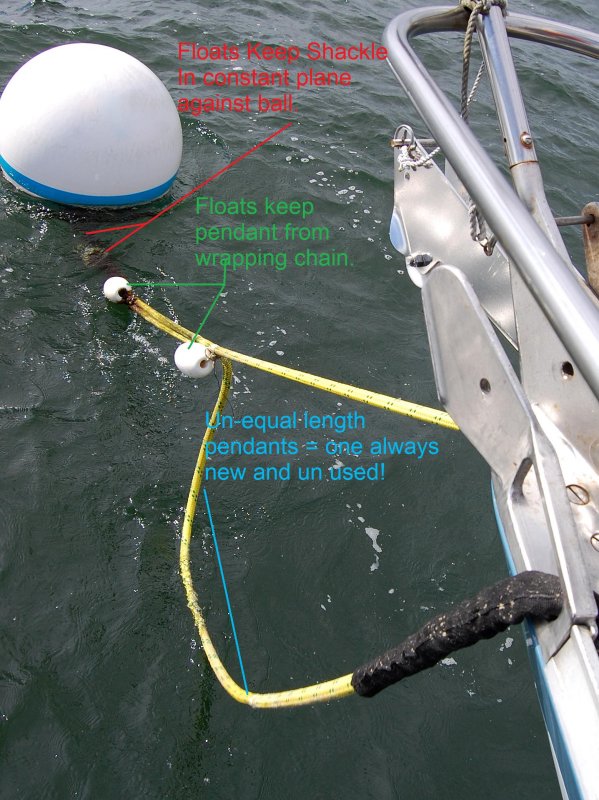

Keeping the shackles in a constant plane, no drooping, is something many mooring installers over look let alone boat owners. It is perhaps one of the single most important aspects to prevent bellow the ball pendant chafe & wraps. The floats should be doubled or have enough flotation to keep the shackles in the same position whether the boat is pulling on the mooring or just sitting idle.

Double floats that remain under the ball & below water keeping the pendants against the under side of it, not out away from it, keep the shackles under constant tension & never let them droop or tangle. I have been lacing pendants like this for well over 12 years and not once have I had a chain wrap or shackle chafe. You also need to continue them to about 4-6 feet from the ball but the most important floats are the ones under water pushing up against the underside of the ball.

This pick is fairly self explanatory:

If you look closely in this photo you'll notice one side of the mooring ball is clean. This is the side where the floats keep the shackles up against the underside of the ball. The shackles are attached to the top of the swivel so are always on the same side of the ball.

It will depend on local ordinances. Around here the system shown in the Hamilton marine catalog is the preferred system and many municipalities have adopted it.

This is probably a lot more info than you want or need but why not..

Mooring tips:

#1 Big heavy chain gives good caternary effect and prevents shock loading.

#2 Moorings are usually designed at a 2:1 or 3:1 max scope, depending upon local regulations, so this means heavy chain is a must if you want any caternary and protection from shock loading.

#3 Chain wears where the links meet. Anchors are not constant duty but moorings are. Moorings are exposed to wear & link degradation 24/7 365 though they should always be winterized to prevent additional chain wear..

#4 The biggest chain, or wire diameter, you can buy will last you the longest.

#5 Galvanized chain adds no real long term benefit as the link wear chews through it rather quickly anyway so self colored chain is fine.

#6 Long link mooing chain is a good option because shackles fit better through it.

#7 You should have a top chain and a bottom chain. The top chain will be lighter than the bottom chain. A good rule of thumb is that the bottom or really heavy chain be 1.5 times max water depth. You will replace the top chain every three to four years depending on your location but bottom chain can last as long as 7-10 if big enough..

#8 Depending on the bottom type you can use: Mud = Mushroom, pyramid or screw. Hard bottoms = Large diameter granite (low and flat is generally considered best). Cement is generally considered a bad idea, by just about every municipality that has studied mooring field failures, and some municipalities have banned it's use as it loses a significant amount of weight bellow water and there are no real "standards". In this vein many have also banned "home made" moorings of engine blocks, cement filled barrels and such. Lots of municipalities now require any home made mooring to first be inspected by the local harbor master.

#9 Many municipalities only allow certain approved mooring companies to set, retrieve, inspect and maintain moorings. The anchorage I'm in now has over 1200 boats and they are very, very strict as to what you can and can not do and who can actually set, retrieve, inspect or work on moorings!

#10 Buy and use the biggest swivel you can. The swivel sees the most wear in the system. I use a 1" swivel and it is money well spent. The swivel should be located just under the ball so you can easily visually inspect it. In areas like a river, with reversing currents, sometimes two swivels are necessary, one below the ball and one between the top and bottom chain.

Feel free to watch this video and you'll see the types of mooring conditions boats in Maine can deal with in the winter and during Nor' Easters. Most boats up here use the Wayne Hamilton mooring protocol as shown bellow. None of the boats in the video broke free despite a few of them having huge breaking waves bashing them. One actually rolled about 80 degrees and popped back up but did not break free.

Please ignore my video skills..

Enjoy...

Why Not to Cut Corners On Your Mooring System (LINK)

Photo Courtesy of Hamilton Marine (LINK)

This is my bottom chain for a 36 footer..

I would not advise an above the ball connection for a number of reasons one being hull scratches and gouges from the shackles the other is tangles & wraps.

Bellow the ball pendant attachments, at least in our anchorage and along the Maine Coast, cause the least amount of problems if done correctly.

With above ball connections, unless you have multiple floats, and this is key, the equator, waist or widest portion of your mooring ball sits bellow the surface of the water you will have problems. If the waist or "equator" of your above the ball connection floats above the surface of the water, seemingly no matter how many floats you have, it will wrap the ball and then get sucked down to the chain as the boat pulls. If the waist is below the surface the floats make the pendants pull over the ball, not under, causing no tangles. With ten+ foot tides up here it is tough to always keep the waist of the ball below the surface as the chain gets lighter and heavier as the tide rises and falls.

I have studied this rather extensively if Falmouth, and by a large margin, below the ball connections wrap much less than above the ball despite the judicious use of floats. It is my conclusion, after physically watching it actually take place, that the "waist" factor is the single biggest problem and cause of wraps not the amount of floats you have.

The ball below marked "Mahoney" is my boat neighbor. I was on board when we had a lull and wind shift. His boat gently moved around the ball and the floats kept the pendants on the surface but circled around the ball. As soon as the wind came up from the other direction and the pendants tightened they were immediately sucked down and into the chain because they were caught under the waist. I took the photo the rowed over and untangled his pendants..

Above ball tangle with floats:

Another one:

Oops another:

Pendants:

Keeping the shackles in a constant plane, no drooping, is something many mooring installers over look let alone boat owners. It is perhaps one of the single most important aspects to prevent bellow the ball pendant chafe & wraps. The floats should be doubled or have enough flotation to keep the shackles in the same position whether the boat is pulling on the mooring or just sitting idle.

Double floats that remain under the ball & below water keeping the pendants against the under side of it, not out away from it, keep the shackles under constant tension & never let them droop or tangle. I have been lacing pendants like this for well over 12 years and not once have I had a chain wrap or shackle chafe. You also need to continue them to about 4-6 feet from the ball but the most important floats are the ones under water pushing up against the underside of the ball.

This pick is fairly self explanatory:

If you look closely in this photo you'll notice one side of the mooring ball is clean. This is the side where the floats keep the shackles up against the underside of the ball. The shackles are attached to the top of the swivel so are always on the same side of the ball.

- Status

- Not open for further replies.