I finally started to do some projects on my trailer. The main thing I wanted to for sure do was to put in a new set of bearings and races, new grease. So far, I have removed one side and found the bearings apearing to be in great shape after nearly 10 years but Ill replace them anyhow.

Im a fan of this trailer.. it looks too simple (like the boat also) but both the boat and trailer now are 26 years old with dang little sign of wear. Ive personally put maybe 15K miles on that trailer.

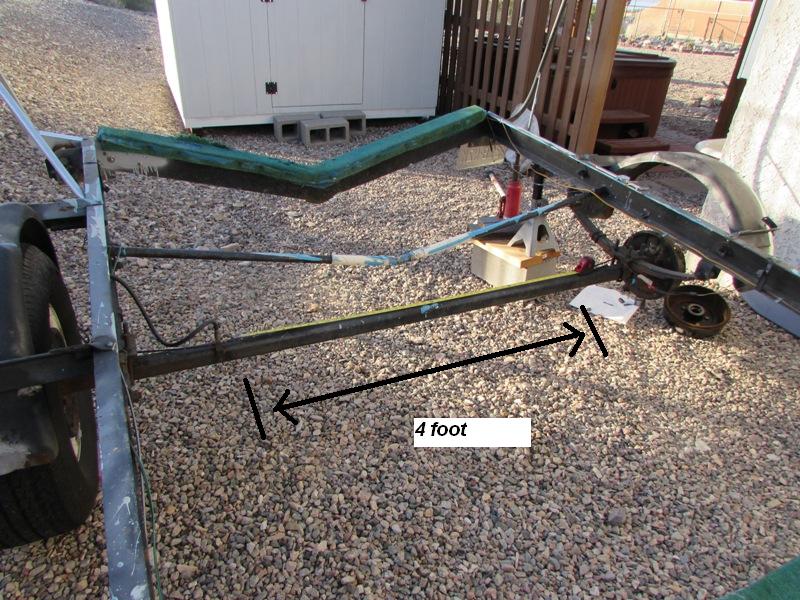

I like the single axle (for a bunch of reasons - but this thread is not about single or double axle) and thought about replacing the axle as mine has a slight bend to it but apparently the Mac trailer axle is some custom size. The axles I found on etrailer were 89 inch hub face to hub face, 74 inch spring to spring or the lighter duty axles are 72 inch hub face to hub face. The axle that is on my 26S trailer is around 81 inch hub face to hub face and 68 inch spring to spring. If I could find a heavy duty "bolt in" axle, I might go that route but will just leave it as is if a hassle is involved.

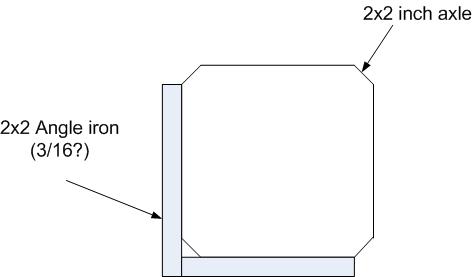

One simple thing I was just thinking about... is to add about a four foot length of angle iron to the axle to stiffen it a little. Four foot length was chosen as I would not have to modify anything on the axle for this to fit. The stiffener would be held on with 4 to 6 Ubolts or something like that. No welding.. just bolt it on with some consideration for corrosion from trapped water.

Is this a bad idea.. dangerous.. etc.. That last picture is the hub after 26 years.. I may also replace the hub and go with disk brakes this year.. or maybe not.. after all, its worked fine for 26 years.

Im a fan of this trailer.. it looks too simple (like the boat also) but both the boat and trailer now are 26 years old with dang little sign of wear. Ive personally put maybe 15K miles on that trailer.

I like the single axle (for a bunch of reasons - but this thread is not about single or double axle) and thought about replacing the axle as mine has a slight bend to it but apparently the Mac trailer axle is some custom size. The axles I found on etrailer were 89 inch hub face to hub face, 74 inch spring to spring or the lighter duty axles are 72 inch hub face to hub face. The axle that is on my 26S trailer is around 81 inch hub face to hub face and 68 inch spring to spring. If I could find a heavy duty "bolt in" axle, I might go that route but will just leave it as is if a hassle is involved.

One simple thing I was just thinking about... is to add about a four foot length of angle iron to the axle to stiffen it a little. Four foot length was chosen as I would not have to modify anything on the axle for this to fit. The stiffener would be held on with 4 to 6 Ubolts or something like that. No welding.. just bolt it on with some consideration for corrosion from trapped water.

Is this a bad idea.. dangerous.. etc.. That last picture is the hub after 26 years.. I may also replace the hub and go with disk brakes this year.. or maybe not.. after all, its worked fine for 26 years.

Last edited: