what a mess! I stripped the nut on the crankshaft pulley while trying to un seize the engine! I took the nut off and tried reversing the nut and when I cranked it down it kept turning without locking down! I was told that the nut is tapered and niw I can’t get it off it keeps spinning and there is not enough room behind it to put a cats paw behind! Any ideas on how I can get it off without destroying the pulley? I tried with a forward cutting blade 1 inch wide for steel but it wasn’t getting anywhere with that plus I had to ride above the crankshaft threads! All ideas welcome here o how to get the nut off without ruining the threads?

Hunter 34 stripped nut on crankshaft pulley

- Thread starter hunter healer

- Start date

Dremel type tool with a diamond cutting wheel. Cut the nut across a flat (fore/aft cut) then chisel it open with chisel horizontal and aimed aft so as to not booger the threads on the crankshaft (if they aren't already toast)

Good luck..

Good luck..

There is a tool for cracking open a nut. looks a bit like a c-clamp with a chisel point at one end and a hex bolt opposite. Just clamp it over the flats on the subject nut and crank it down until the nut fractures. (the tool is available in different sizes) As I recall, they are not very expensive,and probably available at an auto parts store.

There is a tool for cracking open a nut. looks a bit like a c-clamp with a chisel point at one end and a hex bolt opposite. Just clamp it over the flats on the subject nut and crank it down until the nut fractures. (the tool is available in different sizes) As I recall, they are not very expensive,and probably available at an auto parts store.

Thanks for you reply! Unfortunately the crankshaft stub with threads is recessed inside the pulley and the nut has only 1/2 inch clearance around the nut inside the pulley.

This is what I thought and the reason I suggested putting up a photo, pictures worth a thousand words.....Thanks for you reply! Unfortunately the crankshaft stub with threads is recessed inside the pulley and the nut has only 1/2 inch clearance around the nut inside the pulley.

Here's an idea that I used successfully on a similar issue: Using a small drill bit, drill a hole exactly in the middle of the nut, from the face you're looking at. Once you're through, go up to the next size bit and enlarge the hole. And so on until there is very little material left on the i.d. and o.d. You can then possibly break that material by prying it open with a large flat blade screw driver. Good luckThanks for you reply! Unfortunately the crankshaft stub with threads is recessed inside the pulley and the nut has only 1/2 inch clearance around the nut inside the pulley.

yup.. maybe a little saw? https://www.dremel.com/en_US/products/-/show-product/tools/ms400-multisaw-attachment

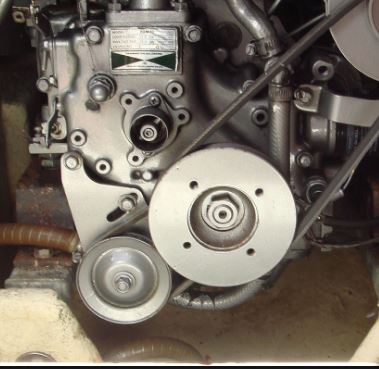

Picture shows recess..

I like Claude's idea of drilling. Probably the most expeditious way to deal with it..

Picture shows recess..

I like Claude's idea of drilling. Probably the most expeditious way to deal with it..

OK I am thinking it looks like this? (upper pulley) which means there is absolutely no room to come at it from the sides, which only leaves looking at this from the end. Drill through the nut with progressively larger sizes until you can break the nut away from the safe. The tough part here is what to do once you have the nut off? sounds like the end of the shaft is devoid of threads which is a big problem, how does one hold the pulley on with no threads left on the end of the crankshaft.

You can re-thread the shaft once you have the pulley off. The trick there is to have enough swing on the die holder tool so you can make a full revolution. While I have; moved the die, back rotated the shaft, move the die again, repeat till done, it is not a very fun process to get started. Once you have two threads cut it is pretty straight forward.

I've had great success using a small WELL GROUND(= 60 degree angle) chisel and a baby sledge hammer. acetylene torches also work if you know what you are doing. they also can make things a LOT WORSE if you don't know what you are doing.

The good news is you now know what it "feels like" when you shear off threads and will never have to deal with it again (until your uncle Bob has an issue and remembers you bragging about your success)

I've had great success using a small WELL GROUND(= 60 degree angle) chisel and a baby sledge hammer. acetylene torches also work if you know what you are doing. they also can make things a LOT WORSE if you don't know what you are doing.

The good news is you now know what it "feels like" when you shear off threads and will never have to deal with it again (until your uncle Bob has an issue and remembers you bragging about your success)