The rudder mount rebuild is progressing. The G10 backer plate is on order and i even picked up a little MMA adhesive.

The first order of business is to replace the gap that used to be wood with replacement polyurethane foam. I still had some 4lb 2-part mix from a deck repair so used that, but if had to buy new, it would be 6lb foam. A form was created inside the rudder mount to copy the internal shape, and some cardboard was duct taped to the outside.

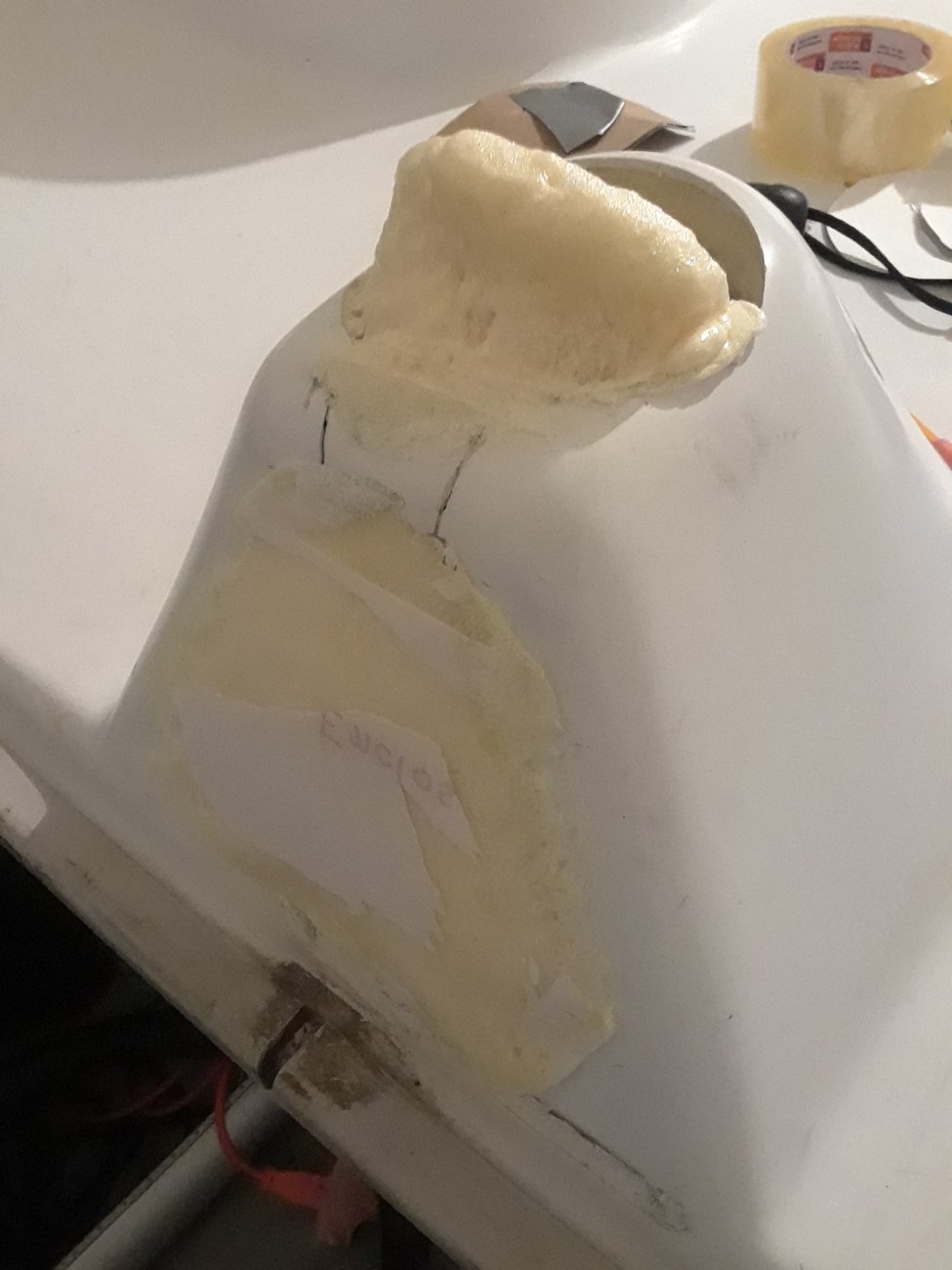

In case of overflow a shield was placed near the top.

The pour went well and overflowed just a little bit. The form was peeled off to expose the new core.

Tomorrow or this weekend the excess will be cut off and the section where the rudder gudgeon attaches will be cleared with a plunge router so the panel can be placed back on.

Ill glass the inside with a couple layers, then glass over the cut out panel to grab the corners. When the G10 arrives ill cut a triangle and epoxy that over the new glass. With excess G10 there should be enough for backer plates on the inside.

In theory, the two G10 layers will compress against new glass, luran, core, and more glass.

The new core is extremely solid even by itself.

Any ideas for a cap for that 4" hole on top. Ill seal it up if i have to but it would be nice to have acess.

The first order of business is to replace the gap that used to be wood with replacement polyurethane foam. I still had some 4lb 2-part mix from a deck repair so used that, but if had to buy new, it would be 6lb foam. A form was created inside the rudder mount to copy the internal shape, and some cardboard was duct taped to the outside.

In case of overflow a shield was placed near the top.

The pour went well and overflowed just a little bit. The form was peeled off to expose the new core.

Tomorrow or this weekend the excess will be cut off and the section where the rudder gudgeon attaches will be cleared with a plunge router so the panel can be placed back on.

Ill glass the inside with a couple layers, then glass over the cut out panel to grab the corners. When the G10 arrives ill cut a triangle and epoxy that over the new glass. With excess G10 there should be enough for backer plates on the inside.

In theory, the two G10 layers will compress against new glass, luran, core, and more glass.

The new core is extremely solid even by itself.

Any ideas for a cap for that 4" hole on top. Ill seal it up if i have to but it would be nice to have acess.

Attachments

-

133.2 KB Views: 408

-

99.5 KB Views: 424