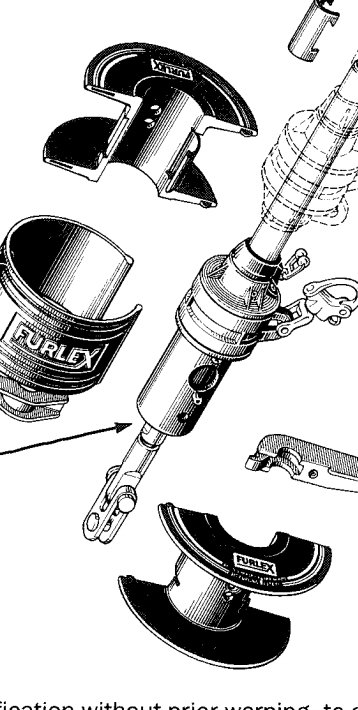

I have a crack in one of the discs in my Furlex Type B MKII roller furler. I am hoping to repair it and wonder if anyone knows what sort of resin it is mace off to help me best select the repair material. Worse come to worse I may just screw half a metal disc to its underside.

Furlex B drum repair

- Thread starter Nesdon

- Start date

In another thread a poster mentioned he found the lid of a large coffee can made a good replacement for the same part... I dont remember the unit type.

Hi Nesdon.

For the time being, your plan to attach a metal disc will se you on the water.

Sam Holmes is printing replacement parts for his rebuild.

This vid is his original 3D printing set up. He has developed it and is using stronger stock.

Worth a try to se what is available in your area or even contact Sam.

Gary

For the time being, your plan to attach a metal disc will se you on the water.

Sam Holmes is printing replacement parts for his rebuild.

This vid is his original 3D printing set up. He has developed it and is using stronger stock.

Worth a try to se what is available in your area or even contact Sam.

Gary

I was thinking of trying to scan it and print it, but this two part drum that snaps together needs some pretty specific sorts of strength and close dimensions

.

It looks like it might be some sort of composite, but it also looks like it might be polypropylene (PP) structural foam, as it has the telltale texture, but it seems too hard and stiff. Maybe structural foam in some other resin? Epoxy sticks well to most stuff, except PP and PE. There are some two part acrylate adhesives that are supposed to bond PP, but my first pass is going to be to rough it up for tooth, and laminate a layer of 3oz cloth on the bottom with epoxy and see what happens.

If one had a decent model and found the right 3D printing filament (polycarbonate?), they could probably sell a lot these things. On my T30, this drum is actually the furthest forward part of the boat, so I expect someone bumped into it at some point. I' ve seen lots of other people looking for the same thing on various forums. It's kind of lame that Selden doesn't stock parts for discontinued systems. They made a die for this thing, which is where most of the cost is, and could probably run them off for a couple of bucks. I get that it complicates their warehousing and supply chain, but for a select few parts with a high failure rate, like this one, I'd think it would be worth it in customer good will. They were selling this model until 10 years ago, and I've read 5 year old posts where folks couldn't find them. I will look for another manufacturer when and if I replace it. This feels, on something as long lived and failure critical as a sailboat, as a sort of planned obsolescence. No thanks.

I had another boat with an Yacht Specialties pedestal steering that had an ABS compass base that was also the boss for the shift and throttle levers. It deteriorated and fell apart, but the company is out of business, so no replacements, tho just like with this drum, while searching for it I found lots of other folks with the same issue needing the same part. I was quoted $700 to scan and print it in ABS by a small shop, so I just built a box out of HDPE board. But a printed version would also likely find quite a few customers.

.

It looks like it might be some sort of composite, but it also looks like it might be polypropylene (PP) structural foam, as it has the telltale texture, but it seems too hard and stiff. Maybe structural foam in some other resin? Epoxy sticks well to most stuff, except PP and PE. There are some two part acrylate adhesives that are supposed to bond PP, but my first pass is going to be to rough it up for tooth, and laminate a layer of 3oz cloth on the bottom with epoxy and see what happens.

If one had a decent model and found the right 3D printing filament (polycarbonate?), they could probably sell a lot these things. On my T30, this drum is actually the furthest forward part of the boat, so I expect someone bumped into it at some point. I' ve seen lots of other people looking for the same thing on various forums. It's kind of lame that Selden doesn't stock parts for discontinued systems. They made a die for this thing, which is where most of the cost is, and could probably run them off for a couple of bucks. I get that it complicates their warehousing and supply chain, but for a select few parts with a high failure rate, like this one, I'd think it would be worth it in customer good will. They were selling this model until 10 years ago, and I've read 5 year old posts where folks couldn't find them. I will look for another manufacturer when and if I replace it. This feels, on something as long lived and failure critical as a sailboat, as a sort of planned obsolescence. No thanks.

I had another boat with an Yacht Specialties pedestal steering that had an ABS compass base that was also the boss for the shift and throttle levers. It deteriorated and fell apart, but the company is out of business, so no replacements, tho just like with this drum, while searching for it I found lots of other folks with the same issue needing the same part. I was quoted $700 to scan and print it in ABS by a small shop, so I just built a box out of HDPE board. But a printed version would also likely find quite a few customers.

Because the choose not to stock them. They were selling these in 2011, and they stopped stocking replacement parts in 2015. Screw them, they lost my business. I will try to find a manufacturer who supports their products better.

BTW they replied with a non answer to my question about which resin was used in the composite fabrication of the drum with "It is a composite blend." I used epoxy to laminate one layer of 3 oz cloth on the inside, and a rope of roving along the crack on the outside, assuming that the rope wrap would only apply outward force. It seems to be working fine.

BTW they replied with a non answer to my question about which resin was used in the composite fabrication of the drum with "It is a composite blend." I used epoxy to laminate one layer of 3 oz cloth on the inside, and a rope of roving along the crack on the outside, assuming that the rope wrap would only apply outward force. It seems to be working fine.