My Cal 27 freshwater system has never really worked since purchasing the boat last fall. I day sail mostly and use bottled water so it's not been an issue, but I"m planning on a short 2-3 day cruise to see what it's like living aboard, etc., and would like the water system to work for that trip

The issues are the pump runs and water/air is expelled from the two faucets on that boat (galley & head). The PO said the system took 5 minutes or so to fully pressurize before the pump stopped, but my test for 18 minutes with one-stop halfway would indicate otherwise. I need to trace hunt down whatever is causing the failure that keeps the pump running, and started with the pump line stuff in the quest, and am a bit confused about what I see installed presently.

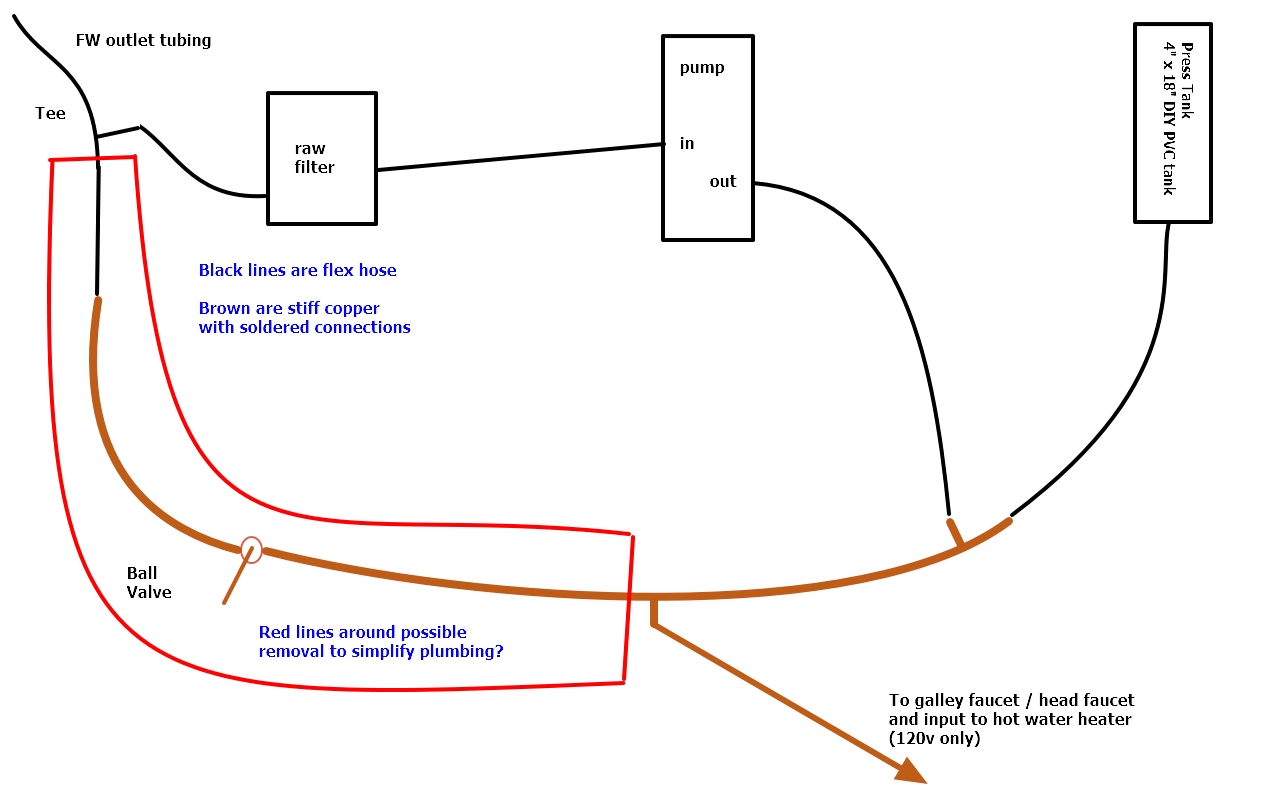

Here is my rather poor drawing of what I have now.

What are the thoughts on removing the valve and stuff inside the red line area in the image? Currently when the valve is closed the pump spits water/air - when open nothing comes out of the faucets.

There is no freshwater hose attachment or fill plate on the boat. Filling the tank means a hose into the opening port below the v-berth.

Thoughts?

The issues are the pump runs and water/air is expelled from the two faucets on that boat (galley & head). The PO said the system took 5 minutes or so to fully pressurize before the pump stopped, but my test for 18 minutes with one-stop halfway would indicate otherwise. I need to trace hunt down whatever is causing the failure that keeps the pump running, and started with the pump line stuff in the quest, and am a bit confused about what I see installed presently.

Here is my rather poor drawing of what I have now.

What are the thoughts on removing the valve and stuff inside the red line area in the image? Currently when the valve is closed the pump spits water/air - when open nothing comes out of the faucets.

There is no freshwater hose attachment or fill plate on the boat. Filling the tank means a hose into the opening port below the v-berth.

Thoughts?